Decorative components for motor vehicle interiors

a technology for decorative components and motor vehicles, applied in the field of decorative components for motor vehicles, can solve the problems of inability to produce pieces with attachment or locking rims or undercuts, requires manual finishing steps, and expensive production processes, and achieves the effect of improving flexibility and adhesion of injected materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

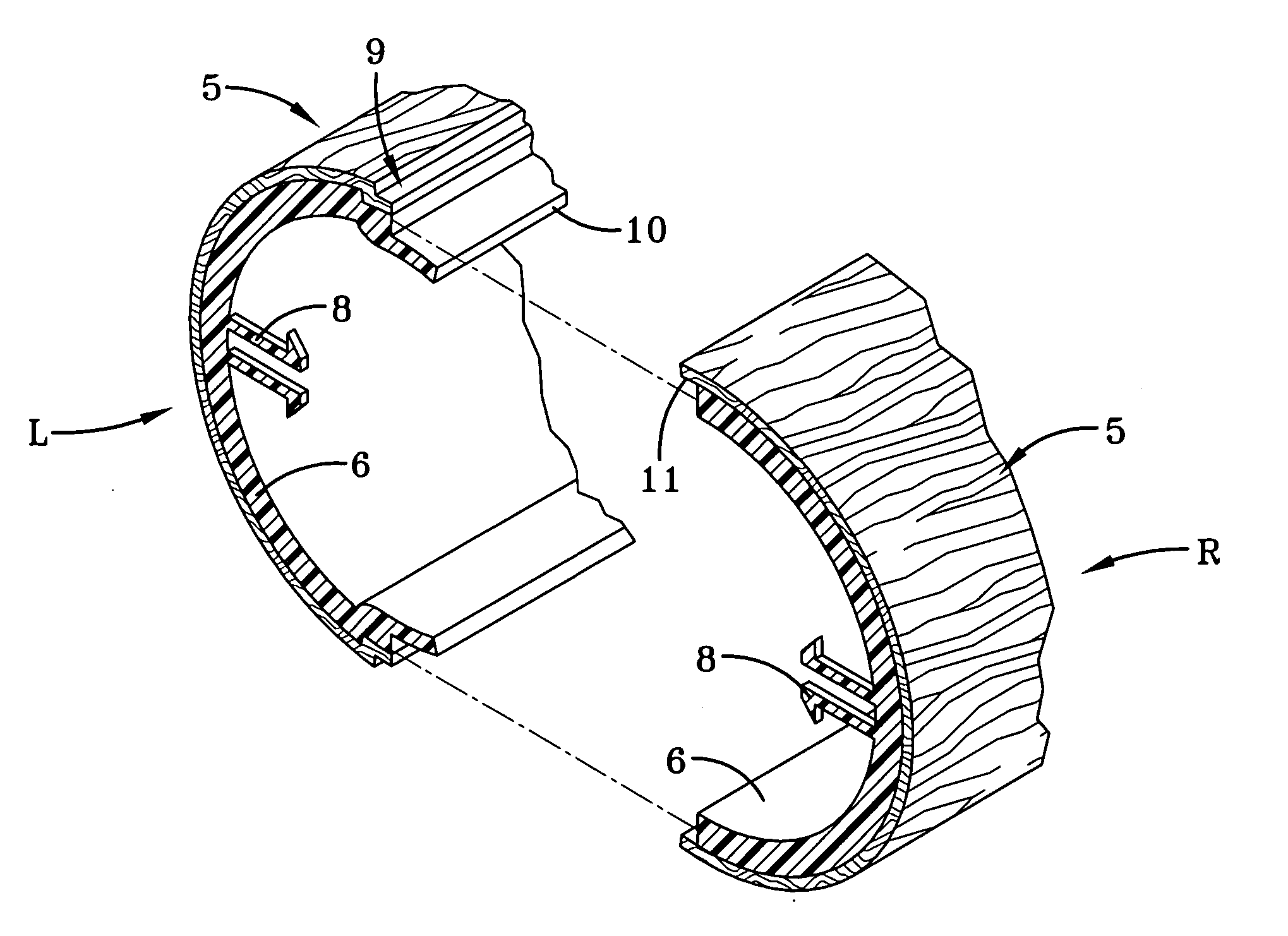

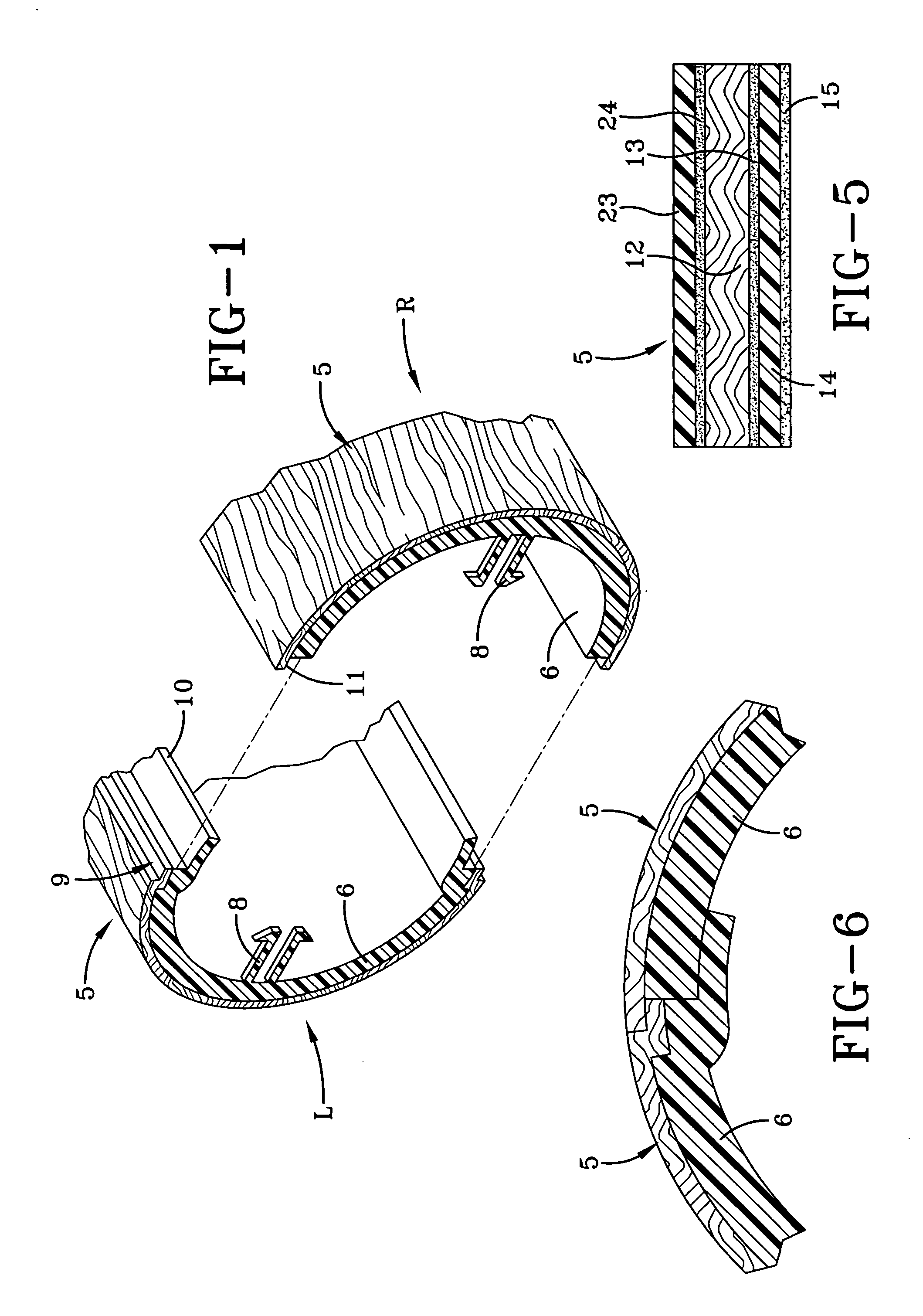

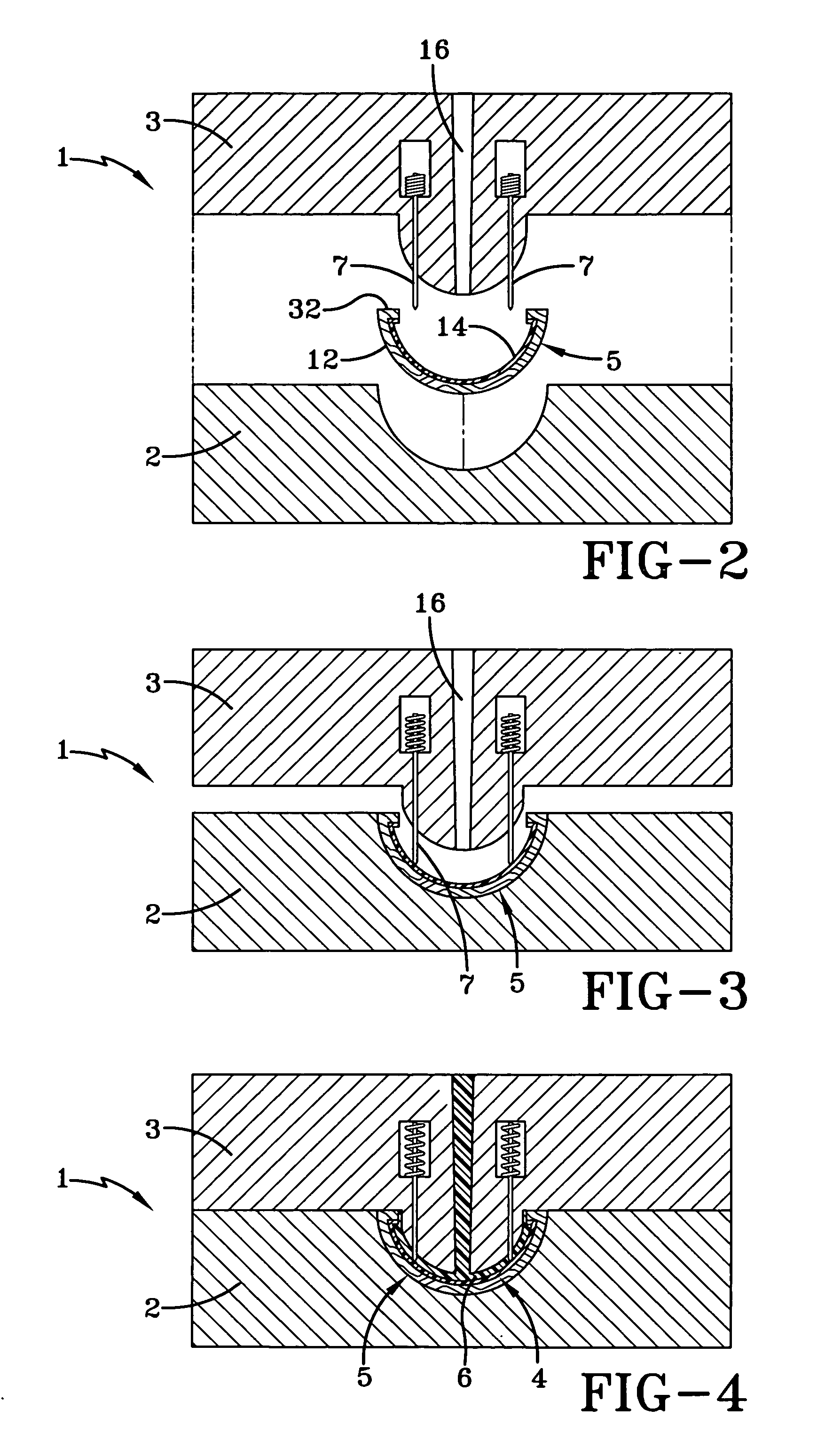

[0054] A formable laminate comprising a wood veneer layer 0.75 mm thick, a thermoplastic material layer 0.21 mm thick and a backing fabric layer, having a total thickness of 1.1 mm is cut to an arched shape of 130° C. The thus cut laminate is preformed in a pre-forming mold as above disclosed for 50 sec at 90° C. and 4.8 bar (pressure of the fluid fed to the inflatable bladder). The pre-formed laminate was then positioned in a mold and retained in position by suction means. A 30% fiberglass reinforced polyamide was injected on the back of the laminate to give a half shell with a perfect shape and without cracks of the wood layer. The injected supporting layer of thermoplastic material is provided with integral hooks for mounting on the steering wheel structure. After finishing and light sanding the shell is lacquered and polished to give an excellent decorative component that can be fit to a steering wheel.

[0055] Returning to the “In Mold” molding step of the pre-formed sheet, it h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com