Semiconductor device and method of manufacturing same

a semiconductor and semiconductor technology, applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of difficult local stress application to soi devices, limited application range of soi technology, and self-heating problems of devices formed on silicon layers, etc., to achieve effective address the floating effect of substrates, reduce junction resistance, and increase carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments of the invention are described below with reference to the corresponding drawings. These embodiments are presented as teaching examples. The actual scope of the invention is defined by the claims that follow.

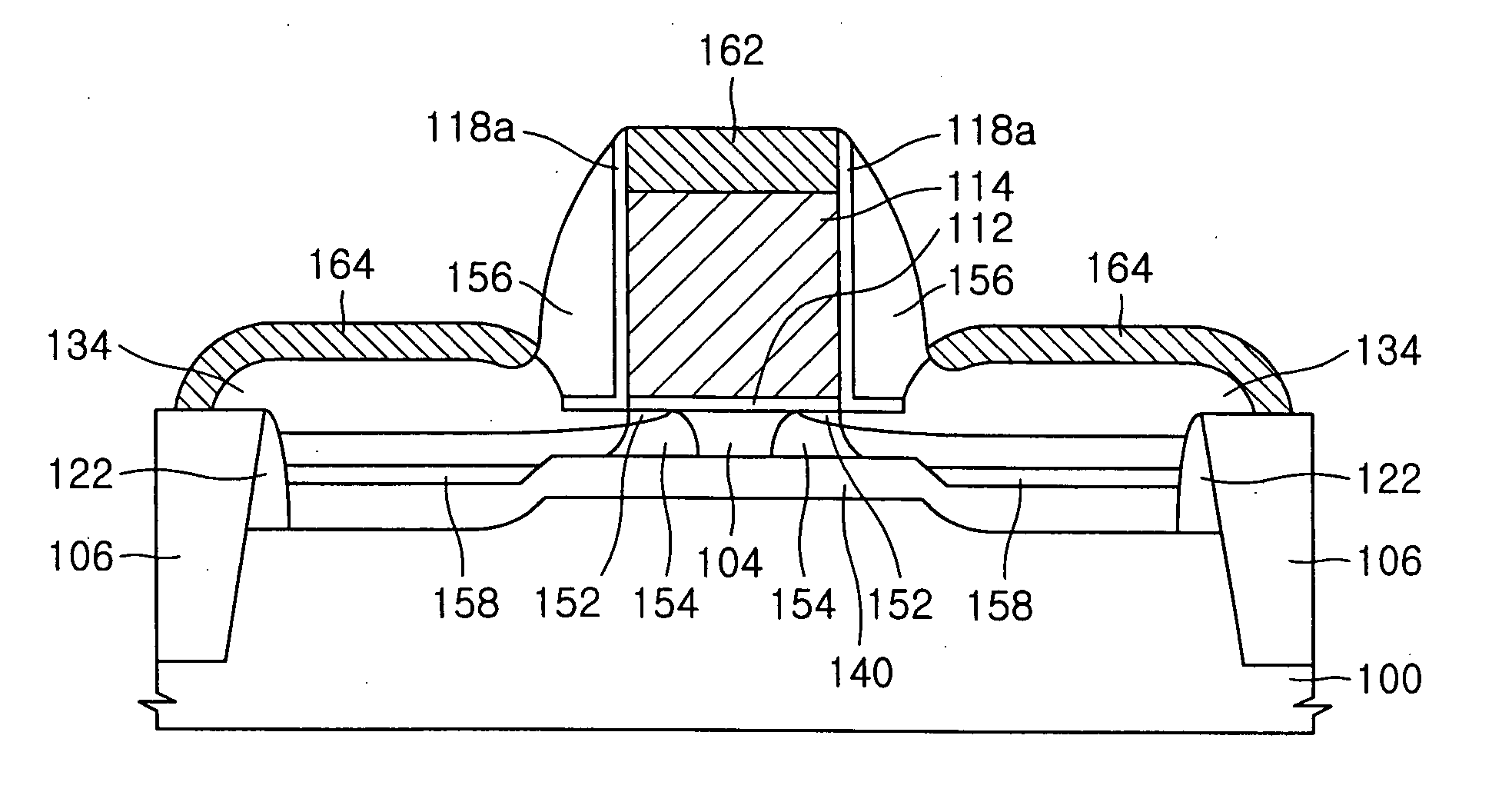

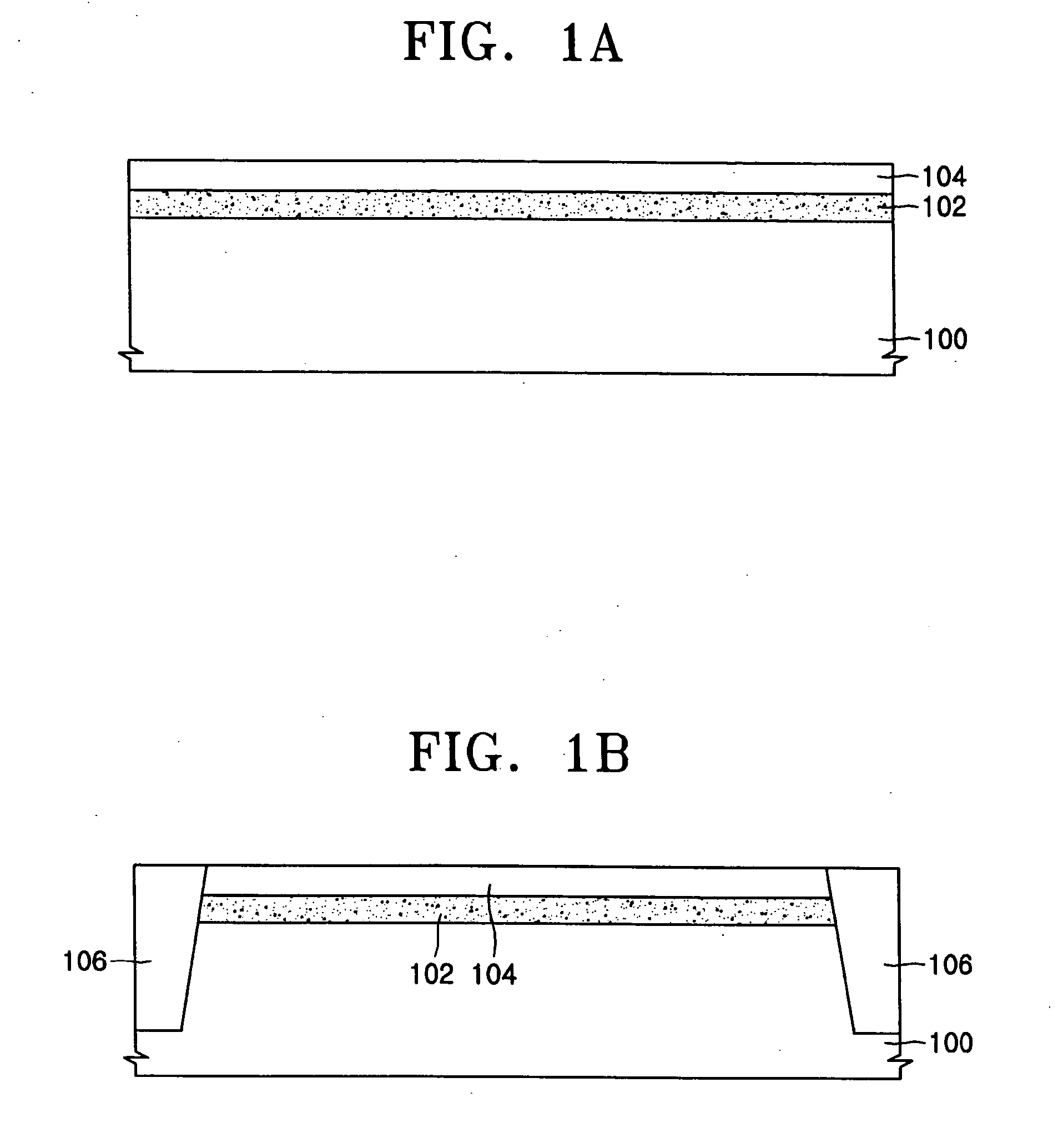

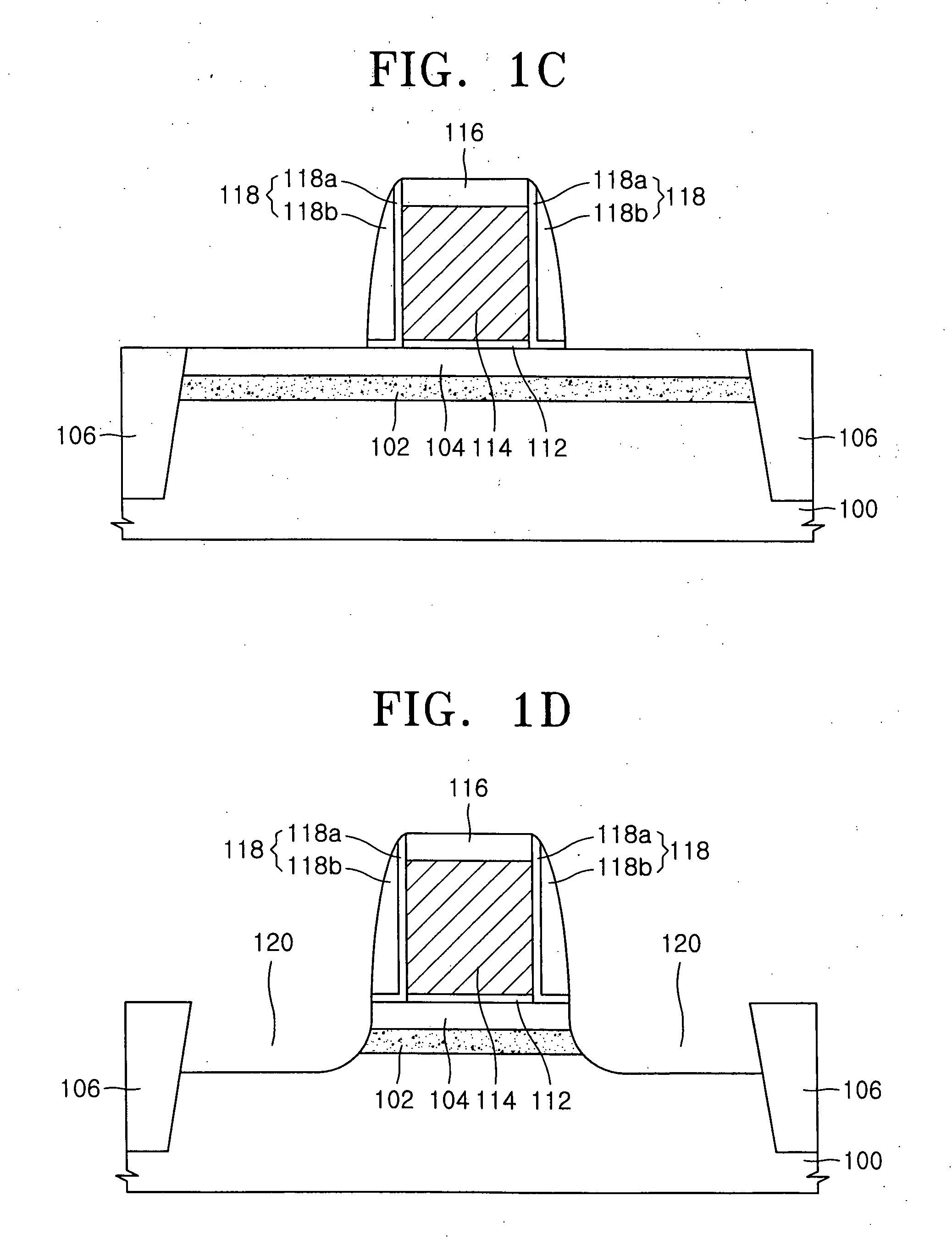

[0022]FIGS. 1A through 1M are cross-sectional views illustrating a method of manufacturing a semiconductor device according to one embodiment of the present invention.

[0023] Referring to FIG. 1A, a first silicon germanium (SiGe) layer 102 is formed on a bulk semiconductor substrate 100 such as a silicon substrate. First SiGe layer 102 is generally formed to a thickness of about 10 to 100 nm using a selective epitaxial growth technology. A silicon (Si) layer 104 is then formed on first SiGe layer 102 to a thickness of about 5 to 50 nm.

[0024] Referring to FIG. 1B, an active region is defined by forming a device isolation region 106 on semiconductor substrate 100 using a conventional isolation method such as a trench isolation method. In other words,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com