Synthetic hydrocarbon products

a technology of synthetic hydrocarbons and hydrocarbon products, which is applied in the direction of hydrocarbon oil treatment products, naphtha treatment, thickeners, etc., can solve the problems of uneconomical formation, high final cost of natural gas, and technological challenges in transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

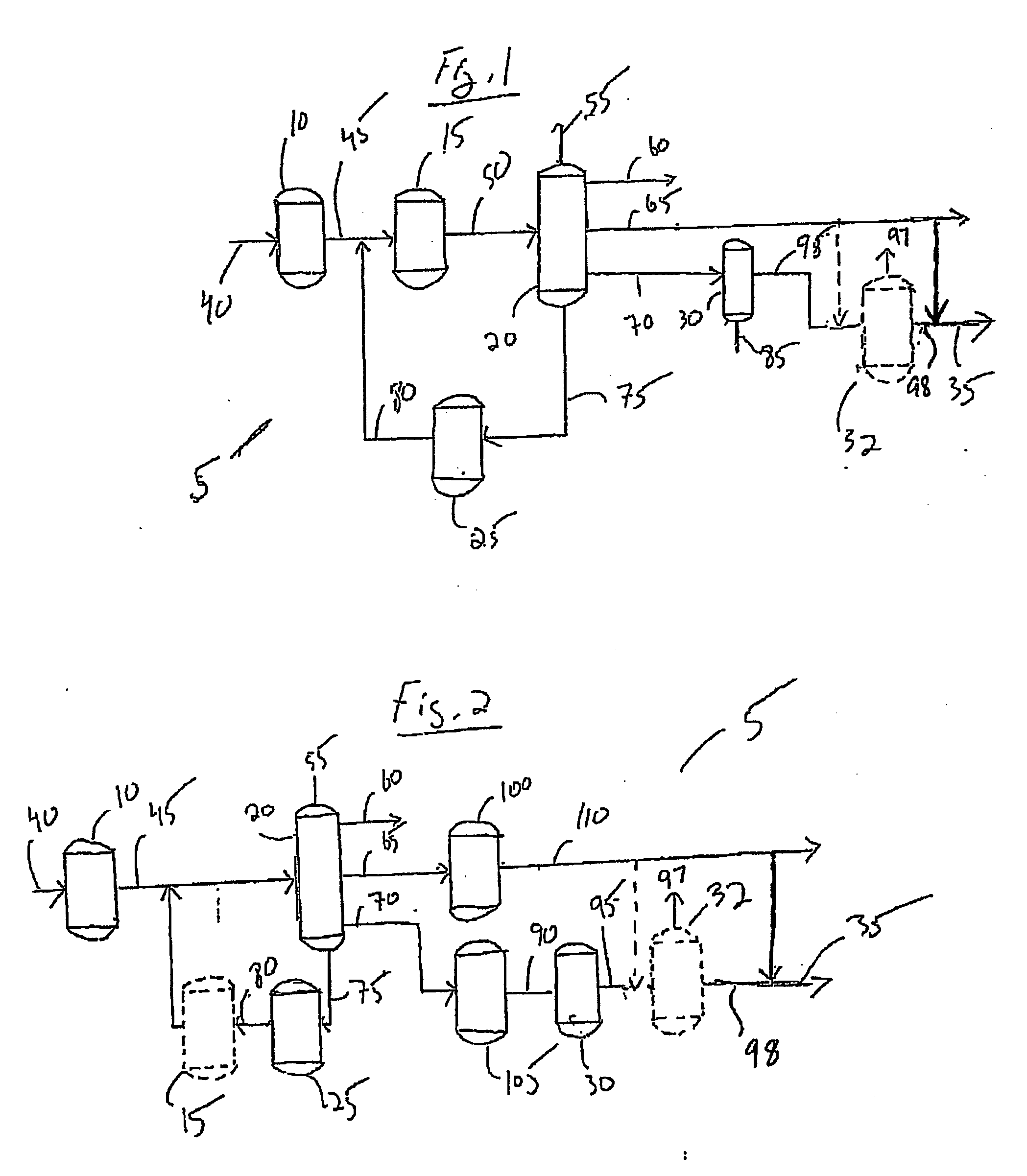

Image

Examples

example 1

[0088] A diesel fraction of straight-run Fischer-Tropsch product was distilled into two cuts, one light cut boiling between 300° F. and 640° F. and a heavy fraction boiling between 640° F. and 1100° F. This straight-run Fischer-Tropsch product was generated by contacting a synthesis gas mixture (with a H2:CO molar ratio of about 2:1) with a cobalt catalyst under typical Fischer-Tropsch reaction conditions (about 430° F. or 221° C.; about 350 psia or 2410 kPa). The straight-run Fischer-Tropsch product was hydrotreated in a hydrotreater comprising a catalytic bed containing about 154 g (200 ml) of a commercial nickel based material (NI-3298 E1 / 16 3F from Engelhard), at a temperature of 375° F. (190° C.), at 390 psia of hydrogen partial pressure in the hydrotreater outlet with a hydrogen flow of 2000 standard cubic feet per barrel of hydrotreater liquid feed (scf / bbl) at a liquid hourly space velocity of 3 hr−1 in trickle flow mode. The heavy hydrocarbon cut obtained after distillation...

example 2

[0089] Using the configuration discussed above, tables II and III below demonstrate the improvement (% or absolute) in the theoretical cloud point relative to 100% straight-run middle distillate as a function of the heavy diesel fraction isomerized and degree of isomerization of that fraction.

TABLE II% ImprovementHeavy DieselDegree of IsomerizationFraction Isomerized0.330.50.850.9576-695° F.8.9%15.4%40.7%48.9%650-695° F.8.9%15.4%39.7%39.7%

[0090]

TABLE IIIAbsolute ImprovementHeavy DieselDegree of IsomerizationFraction Isomerized0.330.50.850.9576-695° F.5.8° F.9.9° F.26.3° F.31.6° F.650-695° F.5.8° F.9.9° F.25.7° F.25.7° F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com