Sealed rolling bearing

a rolling bearing and sealing technology, applied in the direction of shafts, bearings, transportation and packaging, etc., can solve the problems of increasing the torque loss of the bearing and not effectively reducing the attendant friction torque, so as to achieve high sealing performance and reduce the effect of torque loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

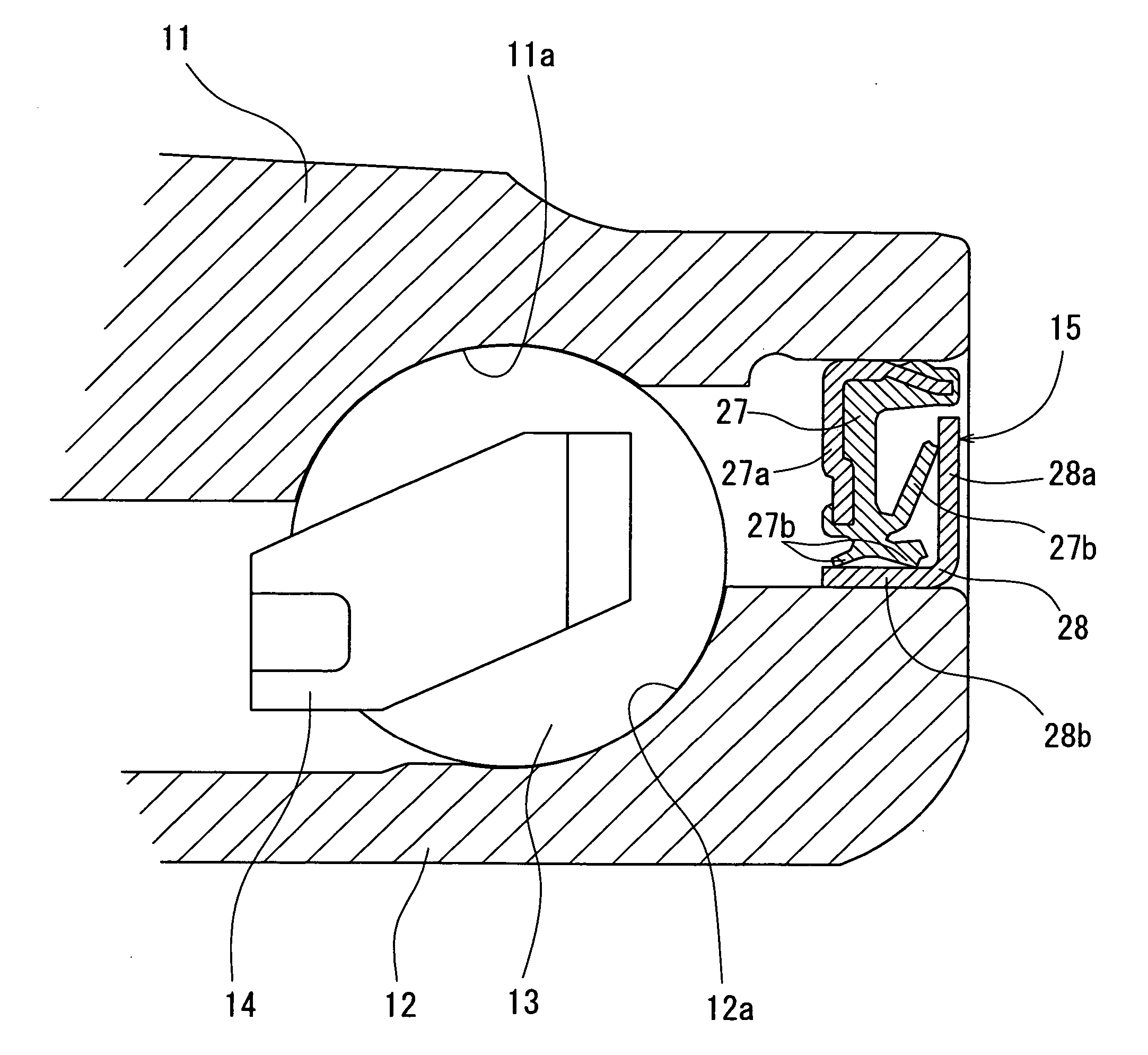

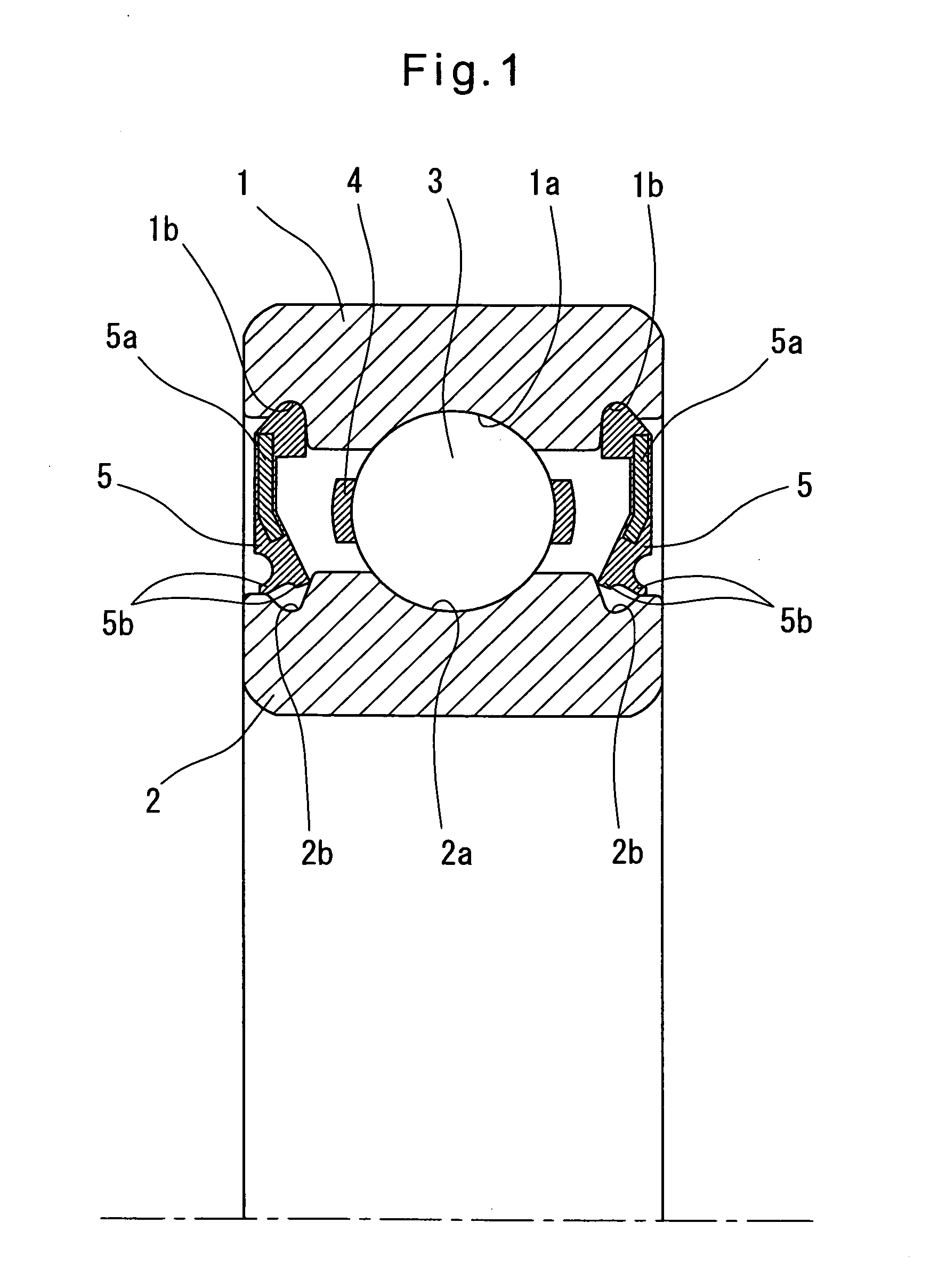

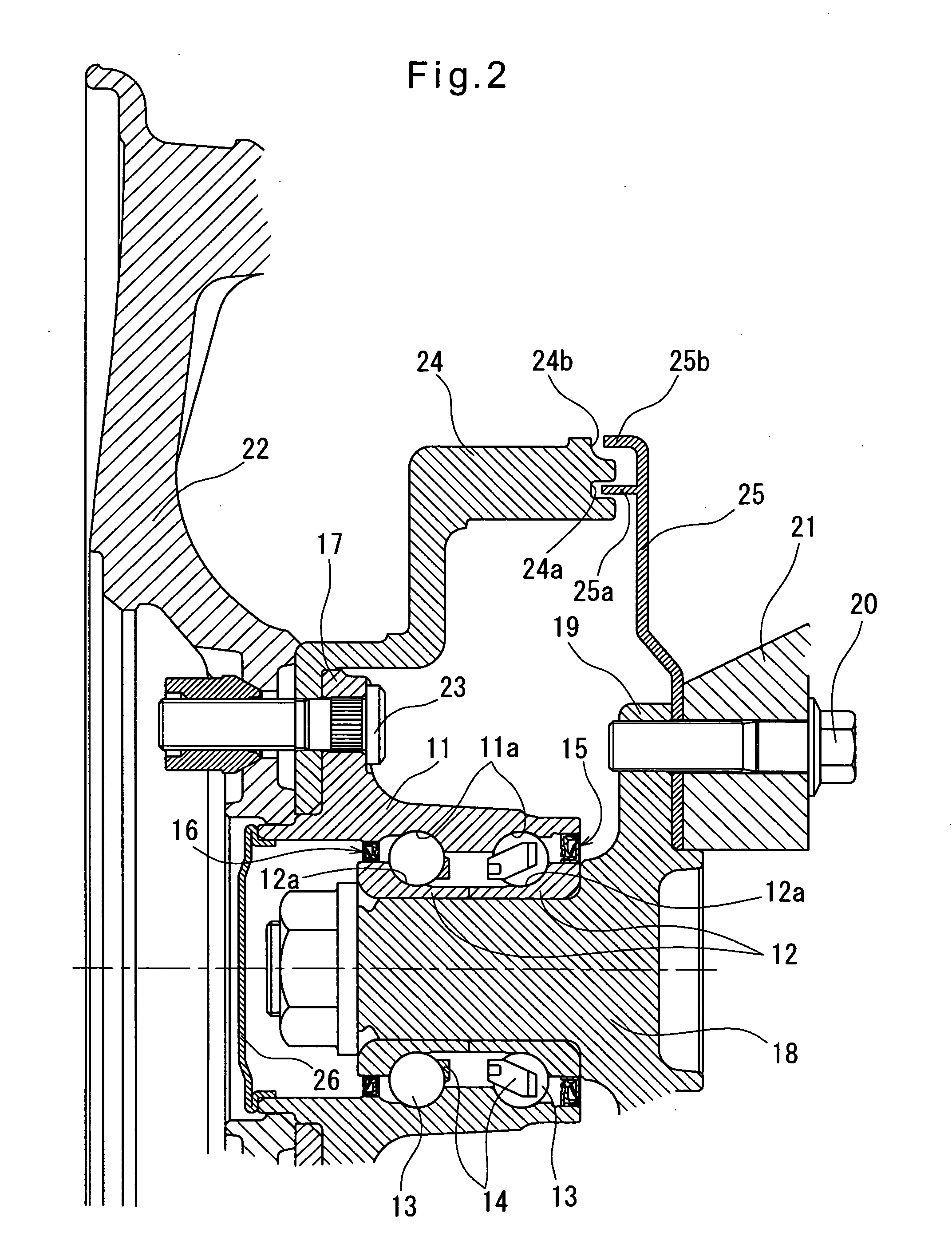

Image

Examples

example

[0037] As Examples, tubular test specimens were prepared which were formed of a stainless steel plate of SUS304 and had their outer peripheral surface subjected to minute shot peening in which minute shots of molybdenum disulfide having a particle diameter of 20 to 200 micrometers were struck against the outer peripheral surface at a speed of 50 meters per second or over. Also, as Comparative Examples, tubular test specimens were prepared which were formed of a stainless steel plate of SUS304, and not subjected to minute shot peening. The tubular test specimens of Examples and Comparative Examples were mounted on a rotary shaft of a rotation tester with lips made of synthetic rubber in sliding contact with the outer periphery of each specimen under a constant pressure, and the rotary shaft was rotated to measure changes in the friction torque between the lips and the respective specimens. The rotation speed of the rotary shaft was changed over between low speed (300 rpm) and high sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com