Flexible puncture resistant sole

a flexible, puncture-resistant technology, applied in the direction of clothing, weaving, fabrics, etc., can solve the problems of inconvenient wear, easy piercing of the sole, injuring the wearer's foot, etc., and achieve the effect of strengthening the piercing resistance function of the composite layer material and high shearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

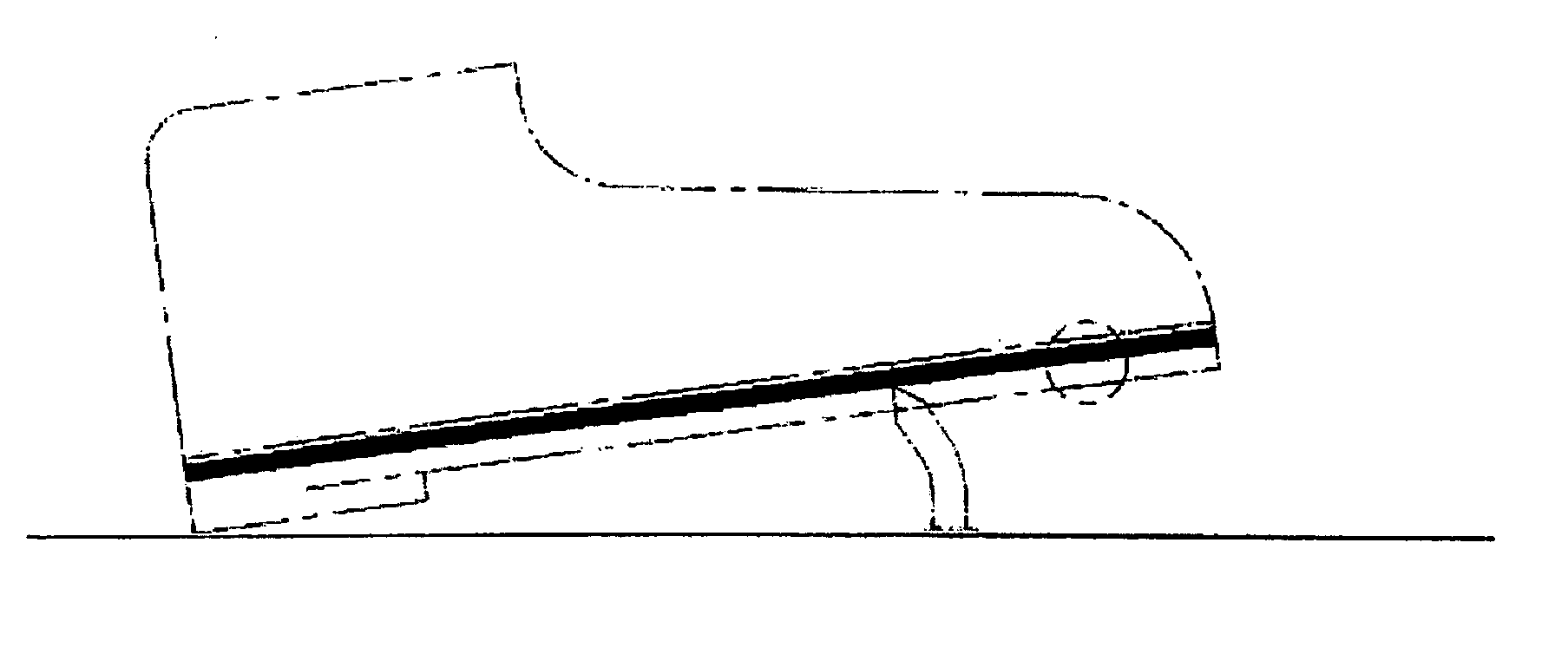

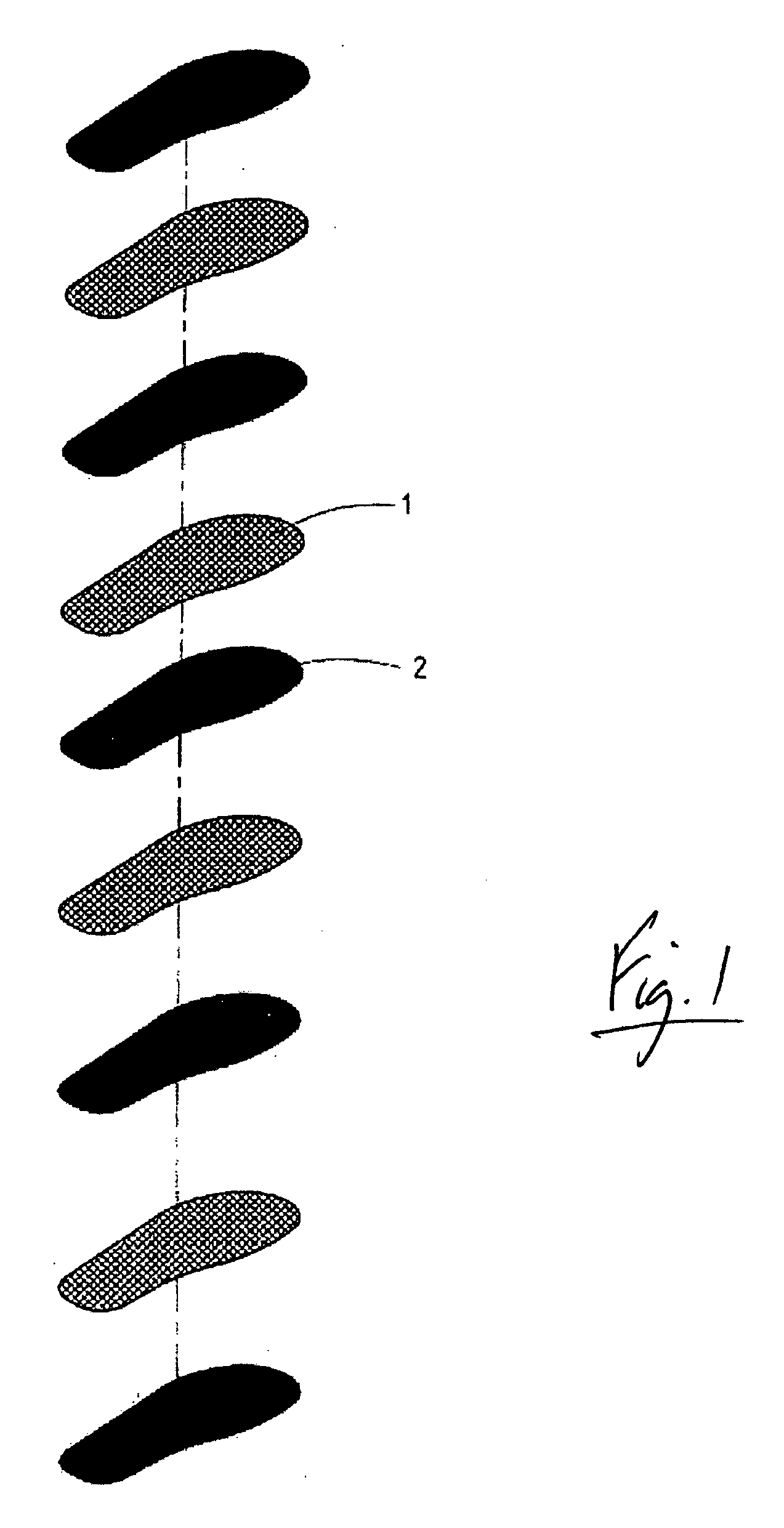

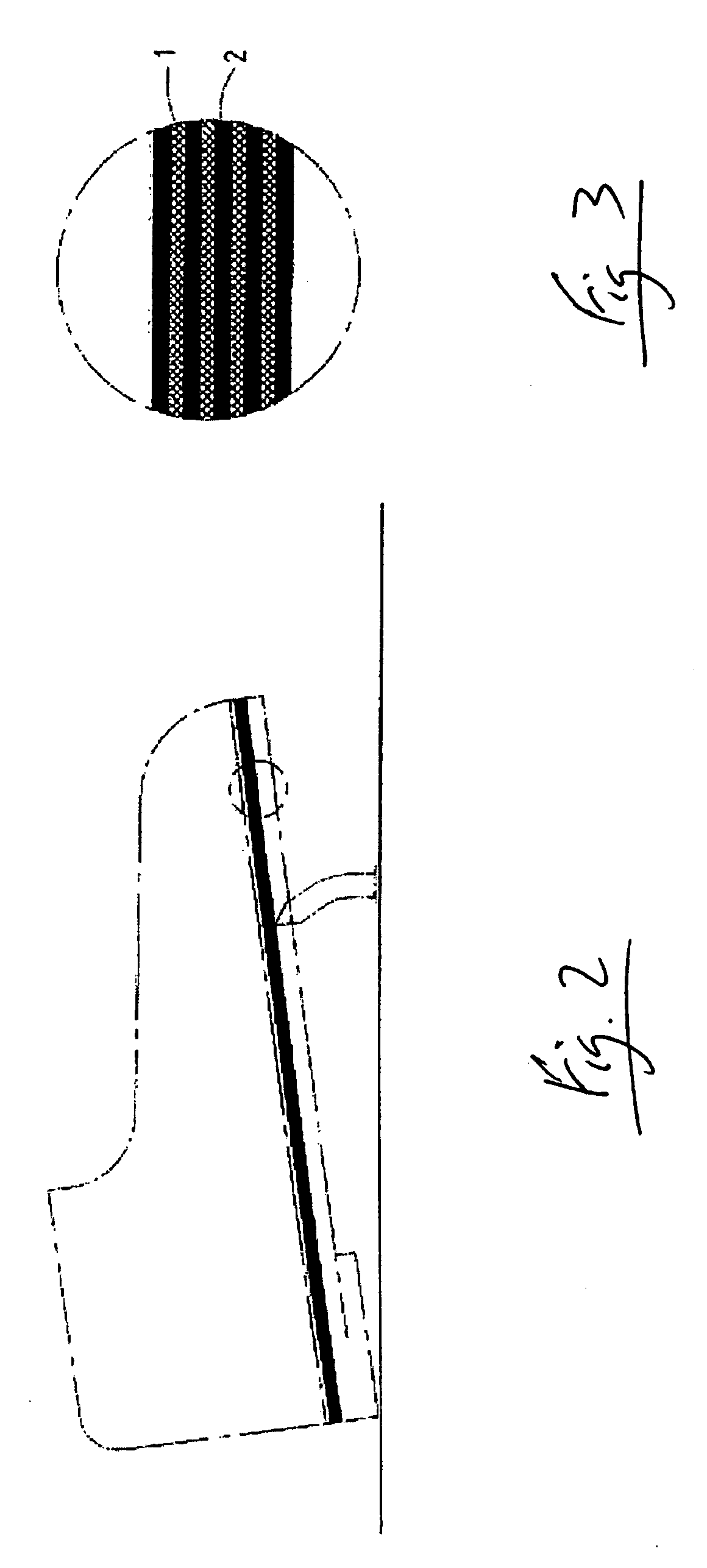

[0015] As shown in FIGS. 1-4, the present invention relates to a puncture preventive structure for the sole of footwear, comprising several woven fiber plies 1 and a layer of bonding agent such as plastic or rubber plies 2 which can be bonded by mutual thermo compression. The material for the woven fiber ply 1 is a high-crystallized polymer fiber polyamide having high shear strength and high tensile strength, for example with tensile strength five times that of a mild steel wire. The woven fiber ply 1 is woven in a common or staggered densely crisscrossed pattern, to improve the resistance to puncture by sharp-pointed articles. The woven fiber plies 1 are bonded with the bonding agent ply 2 which can be rubber or plastic preferably by thermo-compression. Through thermo compression the voids or gaps in the woven fiber ply 1 are filled and smoothed over by the infilling of the bonding agent 2, and yarns or fibers are bonded together to resist movement to strengthen the resistance to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com