Arc-electrolysis steam generator with energy recovery, and method therefor

a technology of arc-electrolysis and steam generator, which is applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of electromagnetic energy and plasma currents not being presently recovered in existing arc-electrolysis processes, and the vastness of the recovery of energy lost during such processes, etc., to achieve high efficiency in the generation of electrical energy and steam, and the effect of reclaiming otherwise wasted energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

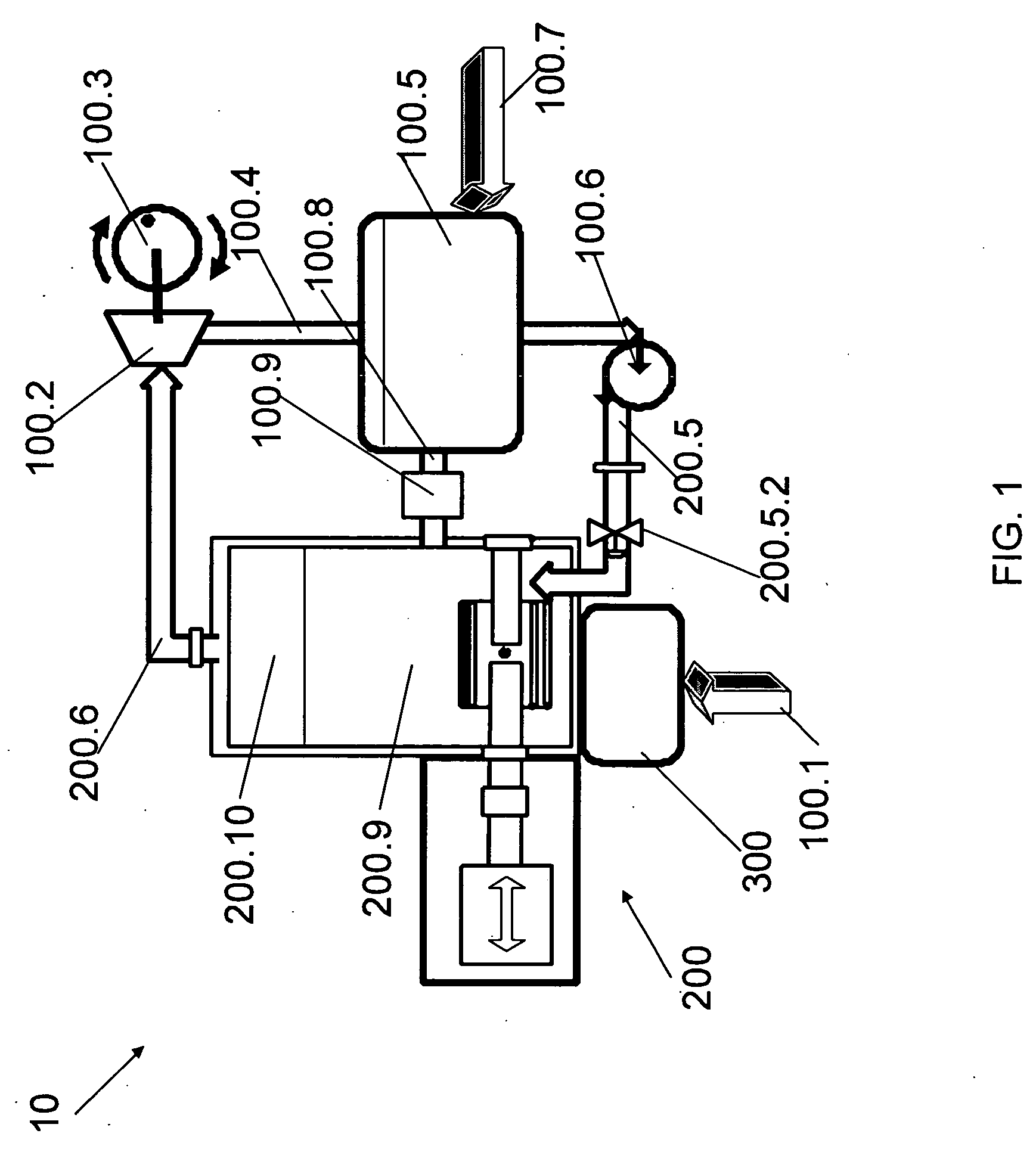

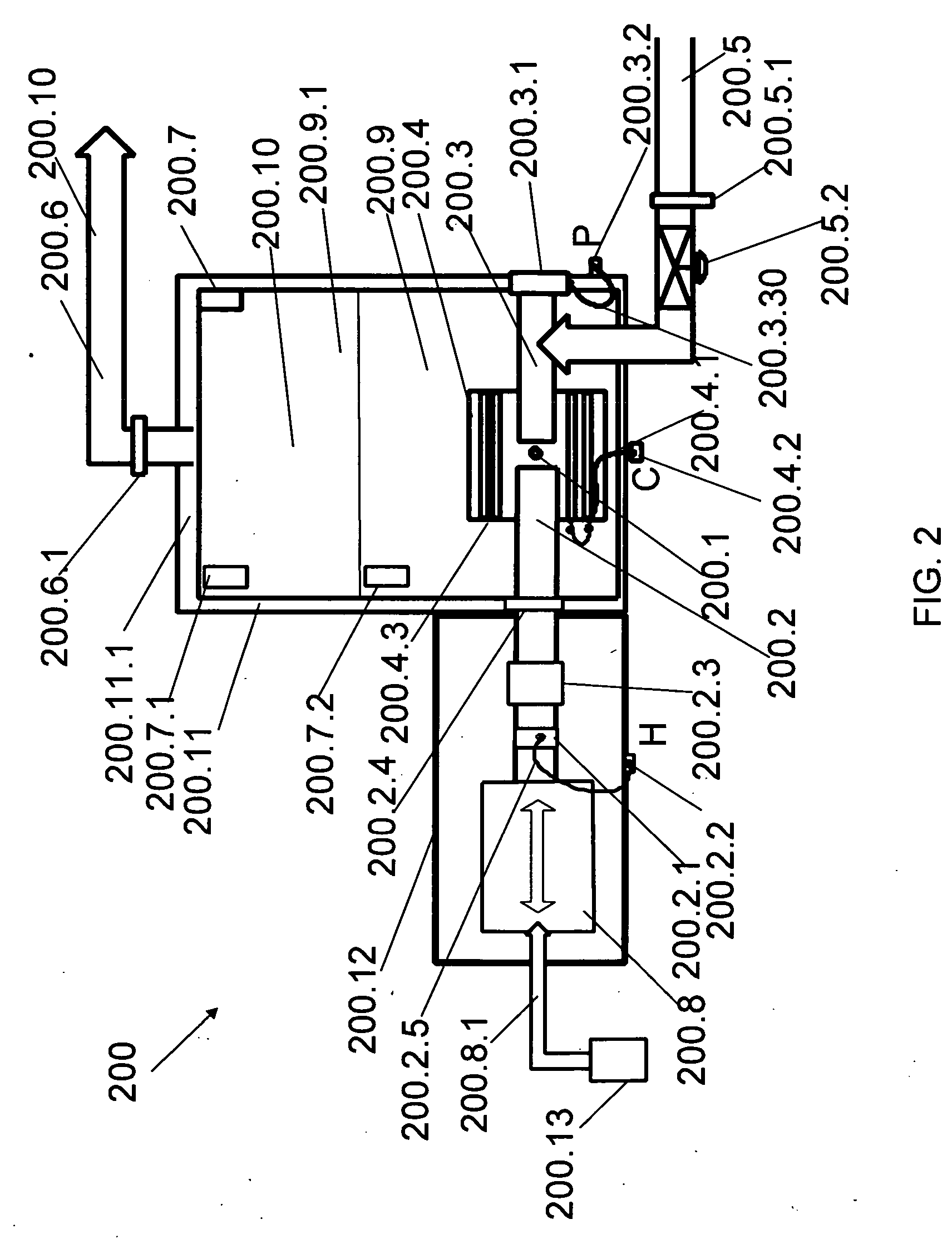

[0046] In describing the preferred and selected alternate embodiments of the present invention, as illustrated in FIGS. 1-4, specific terminology is employed for the sake of clarity. The invention, however, is not intended to be limited to the specific terminology so selected, and it is to be understood that each specific element includes all technical equivalents that operate in a similar manner to accomplish similar functions.

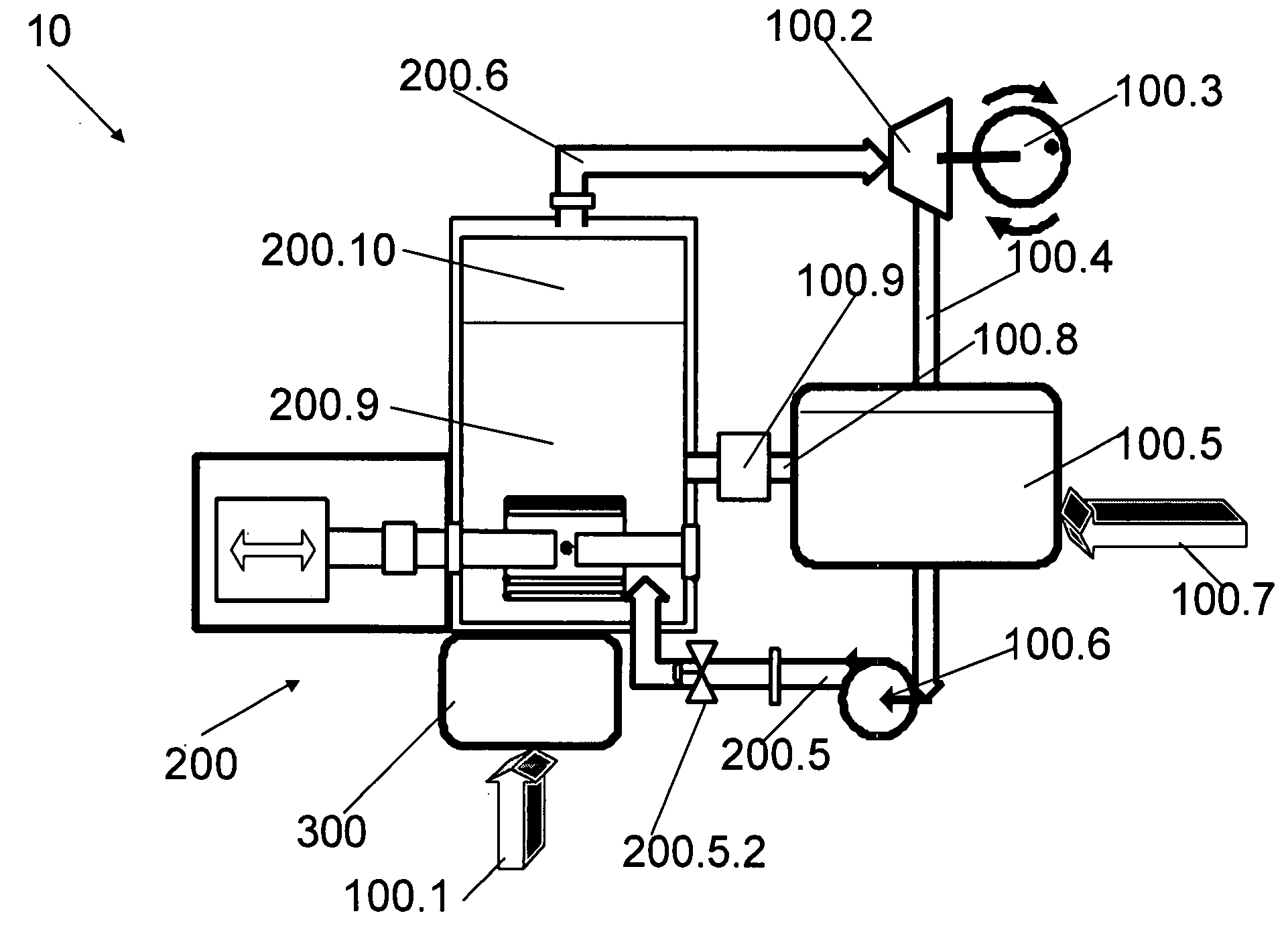

[0047] Referring now more specifically to FIG. 1, the present invention in its preferred embodiment is arc-electrolysis steam generator 10 comprising supplemental electrical external power 100.1, electrical system 300, steam generation system 200 comprising steam turbine 100.2, rotational energy system 103.3, condensate return pipe 100.4, condensate tank 100.5 and condensate pump 100.6. Arc-electrolysis steam generator 10 preferably utilizes electrical energy to power an arc-discharge at arc point 200.1 to ionize solution 200.9 via electrodes 200.2, 200.3 (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com