Multiple fluid heat pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following description of the preferred embodiment is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

[0016] According to the prior art, certain problems occur in the efficient transfer of a thermal load when a hot body to be cooled is located over or above the cold body. That is, in order to accomplish such cooling of the hot body, fluid would flow against its natural tendency (i.e. heat rises and cold sinks).

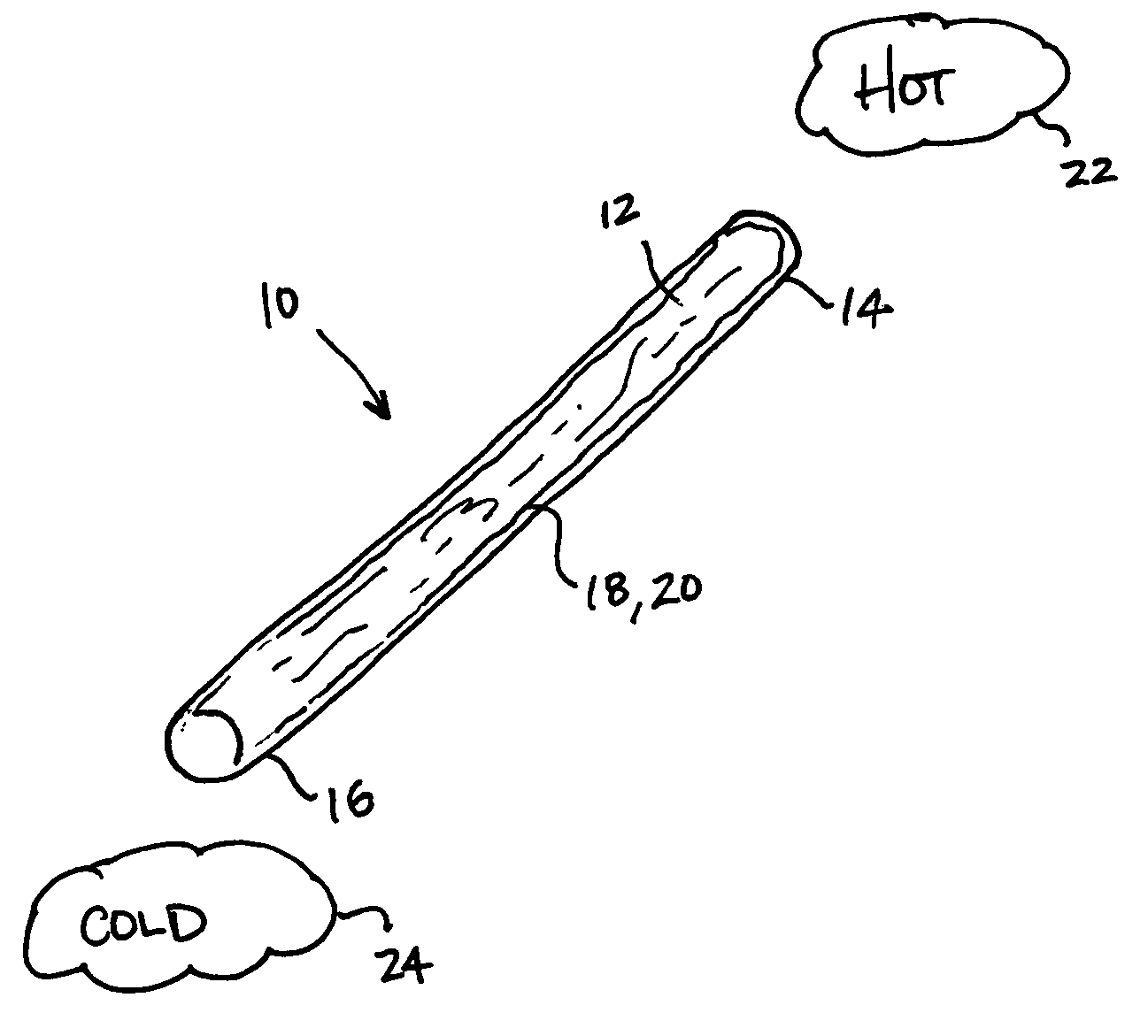

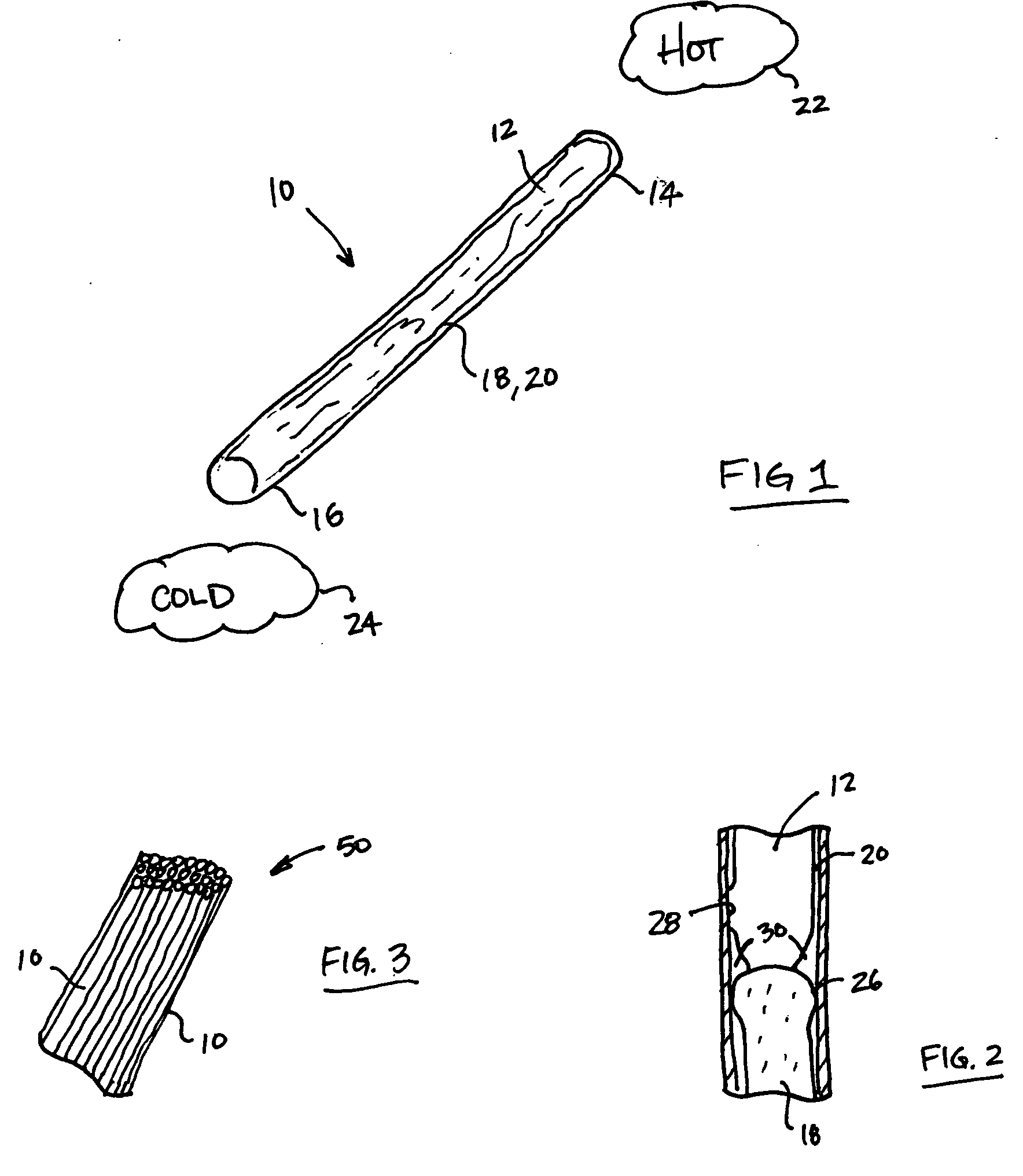

[0017] Typically, a heat pipe is a vacuum vessel containing a relatively small amount of working fluid. The vessel's inner surface is constructed or treated such that the working fluid covers the entire inner surface of the vessel as a thin layer. The vessel is initially evacuated and, thus, it only contains the liquid working fluid on the inner surface and the vapor phase of the fluid throughout the inner volume.

[0018] The amount of heat exchange a heat pipe can handle can be enormous. However, it is usually l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com