Control valve assembly for controlling gas flow in gas combustion systems

a gas combustion system and control valve technology, applied in combustion control, household stoves or ranges, gaseous heating fuels, etc., can solve the problems of difficult packaging and integration of small size chips of mems devices as a part of a macro scale system, and the design of such systems is difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

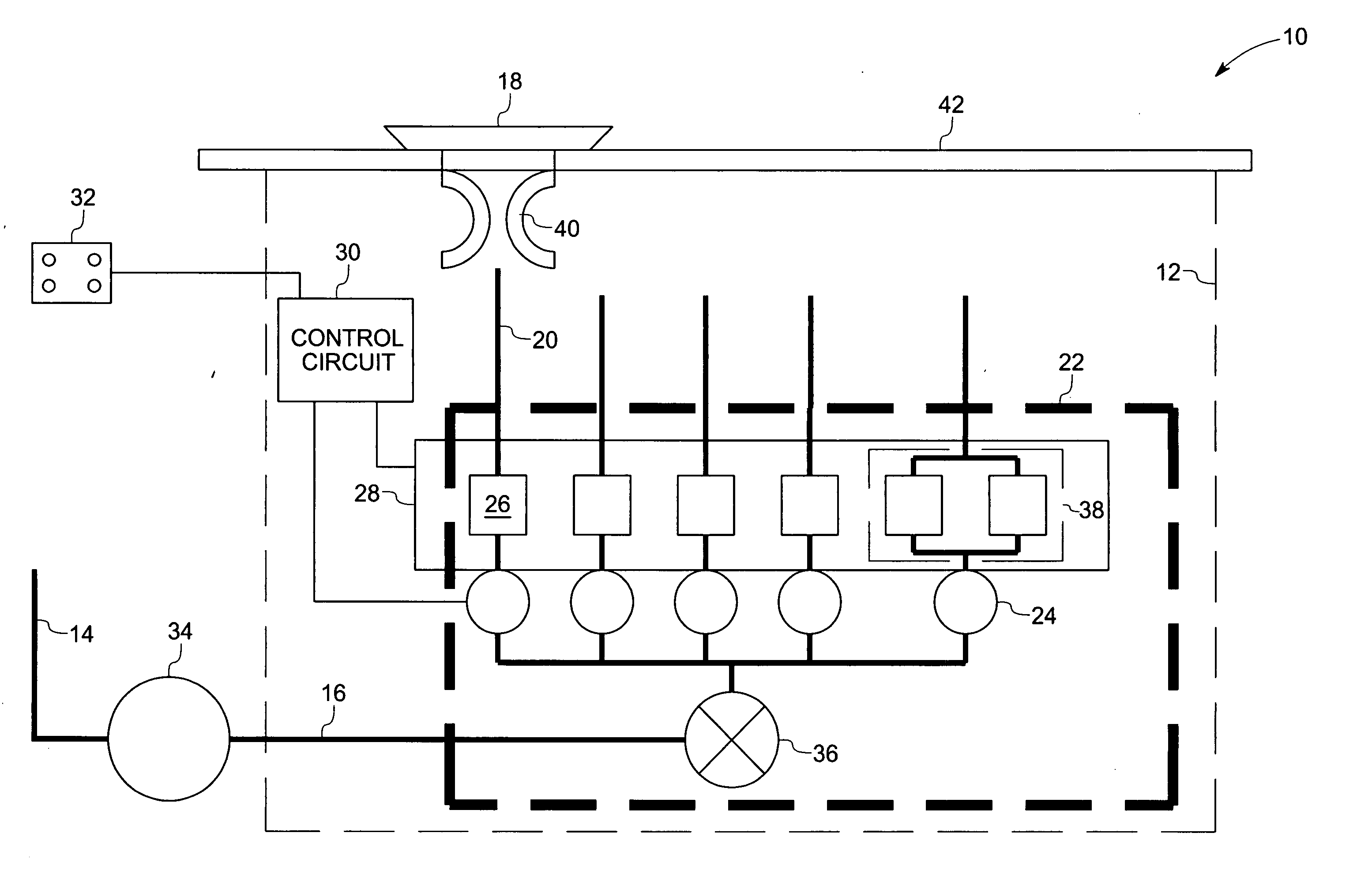

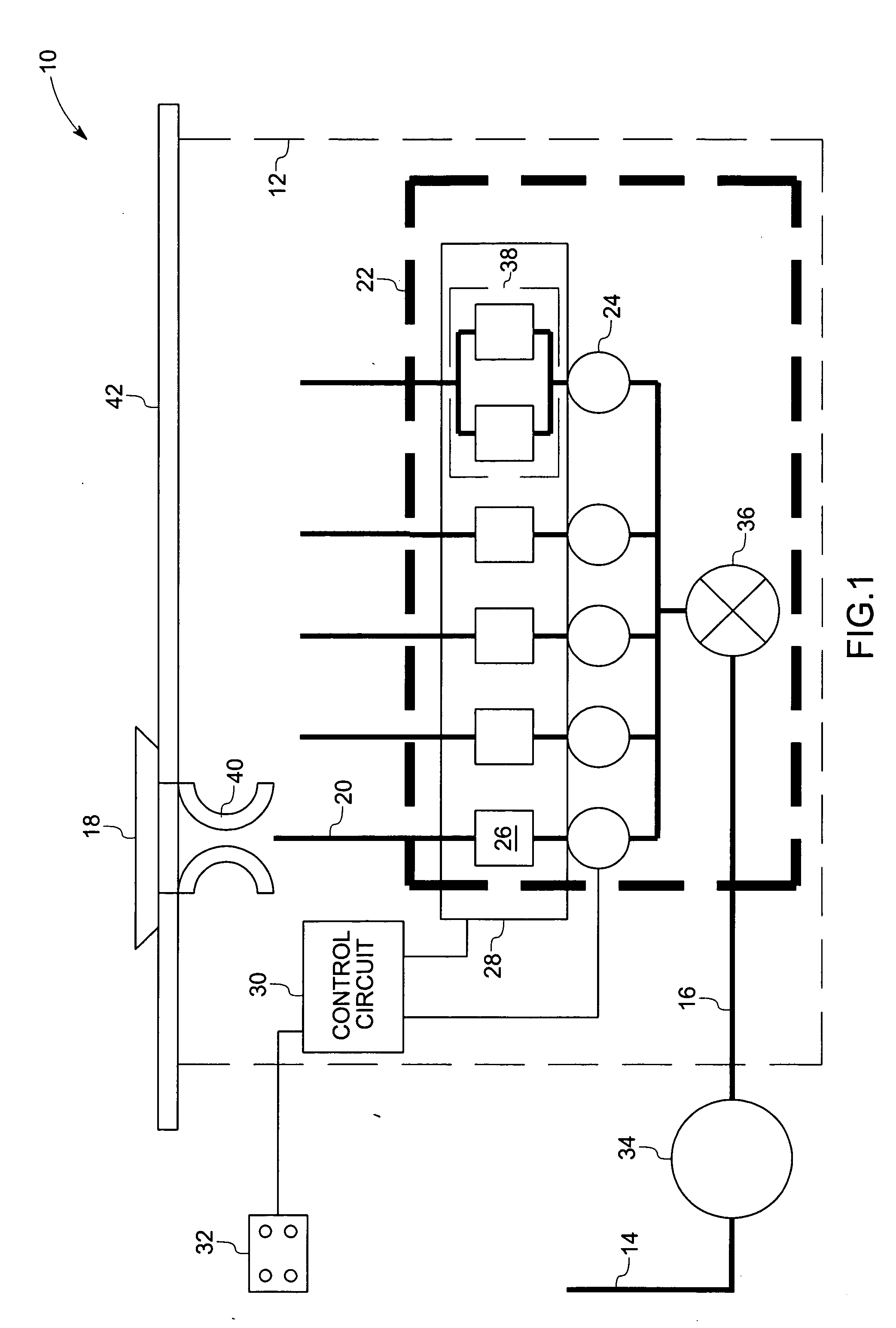

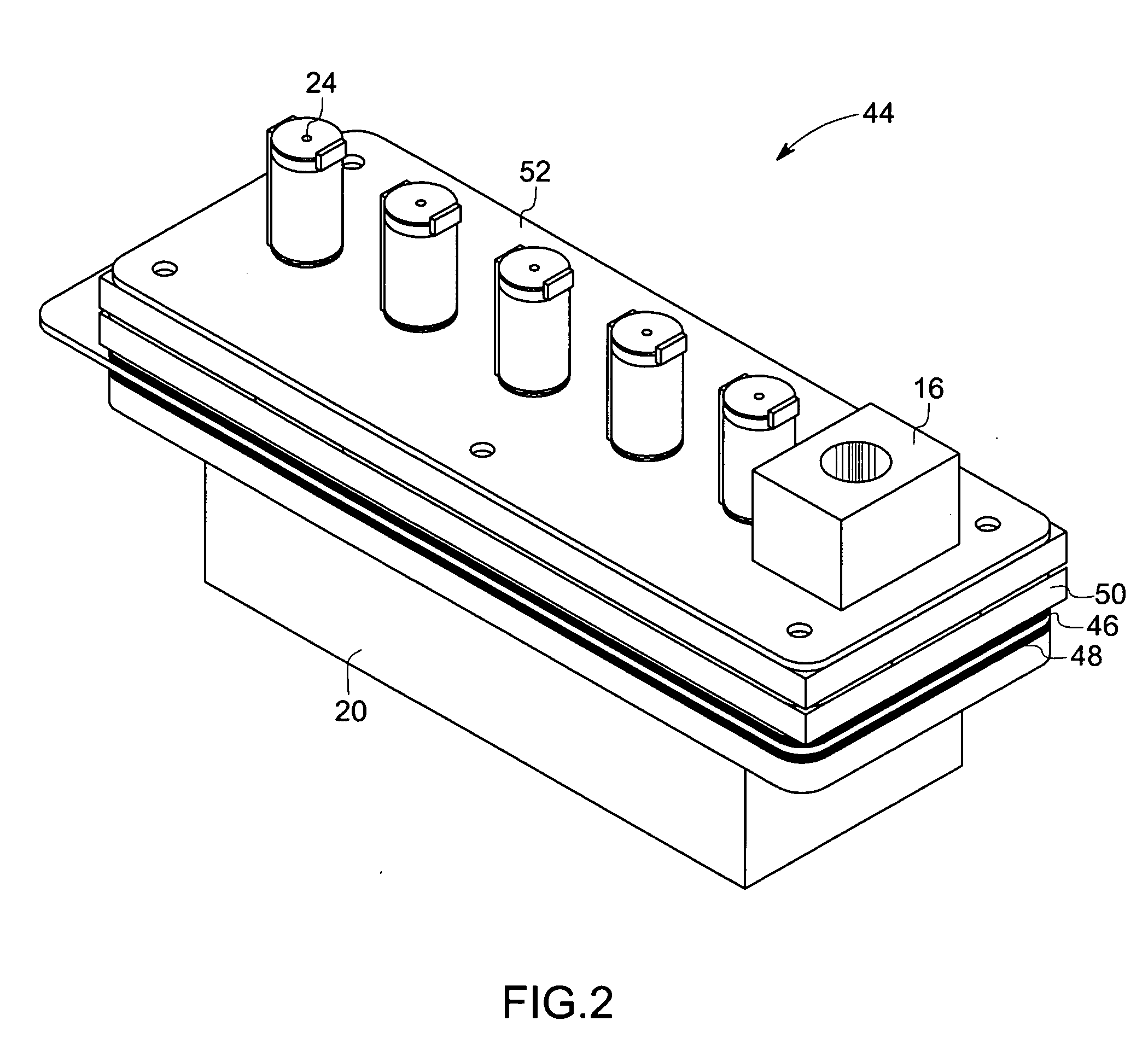

[0021]FIG. 1 illustrates a gas burner system 10 with a control valve assembly, according to an embodiment, for use in a gas operated cooking appliance, such as, but not limited to, gas stove, gas hobs, and gas ovens. In the embodiment illustrated in FIG. 1, the gas burner system 10 includes a series of components disposed in a housing 12. In a presently contemplated configuration, the gas burner system 10 receives a gas flow from a supply 14 via an inlet 16 and the gas flow is delivered to a gas burner 18 via an outlet 20 for use in various cooking activities. A valve assembly 22 with a positive-shutoff valve 24 and a micro electromechanical system (MEMS) valve 26 is coupled between the inlet 16 and the outlet 20 for regulating the gas flow from the inlet 16 to the outlet 20. It should be noted that, the MEMS valve 26 is coupled in series to the positive-shutoff valve 24. In this embodiment, the positive-shutoff valve 24 is disposed upstream of the MEMS valve 26. Further, the MEMS v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com