Method of incorporating carbon nanotubes in a medical appliance, a carbon nanotube medical appliance, and a medical appliance coated using carbon nanotube technology

a carbon nanotube and medical device technology, applied in the field of coating methods, can solve the problems of uneven bioactive agent concentration on the surface of the device, limited ability to apply thin coatings on products, and affecting the treatment of the affected part of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

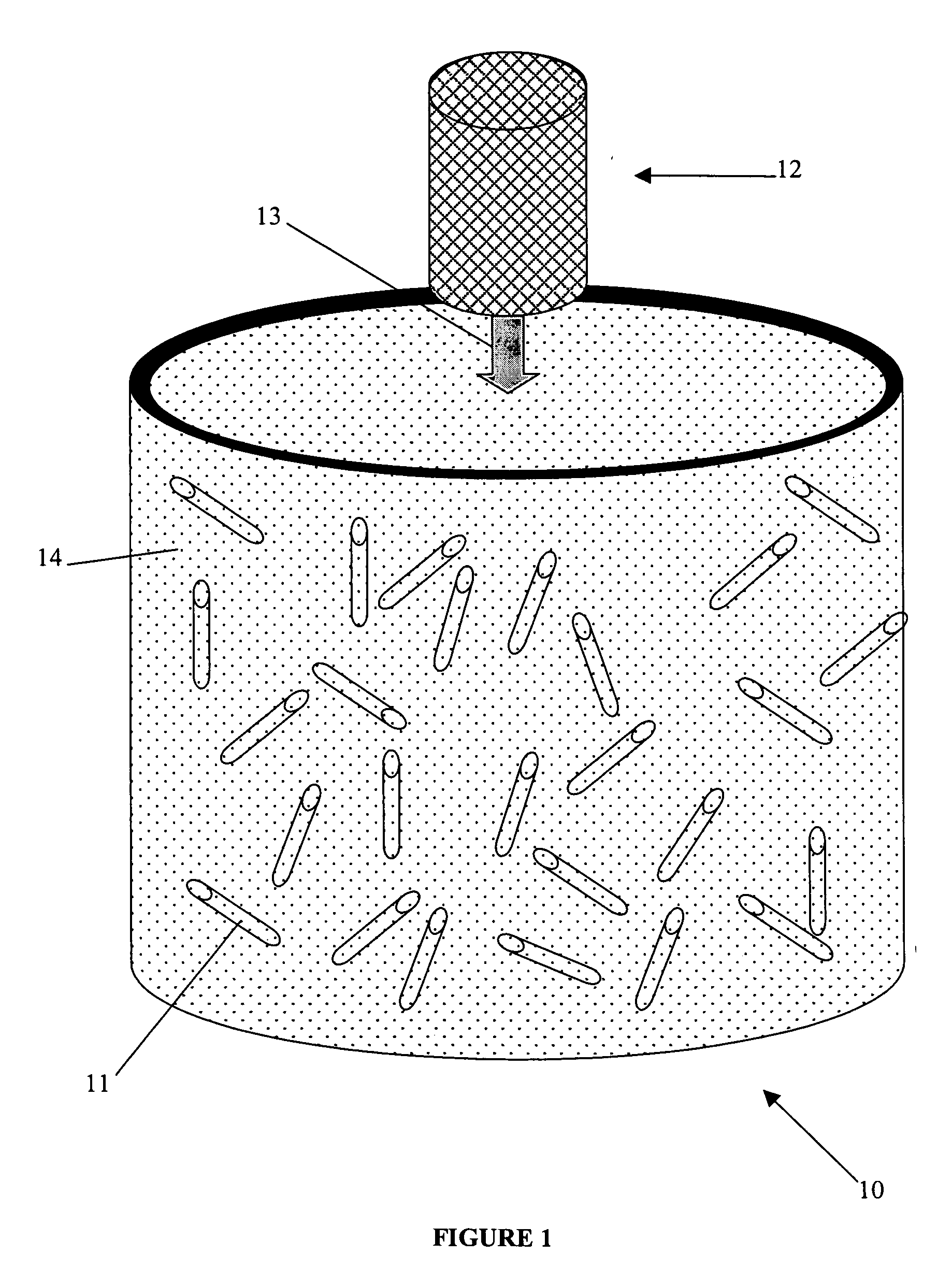

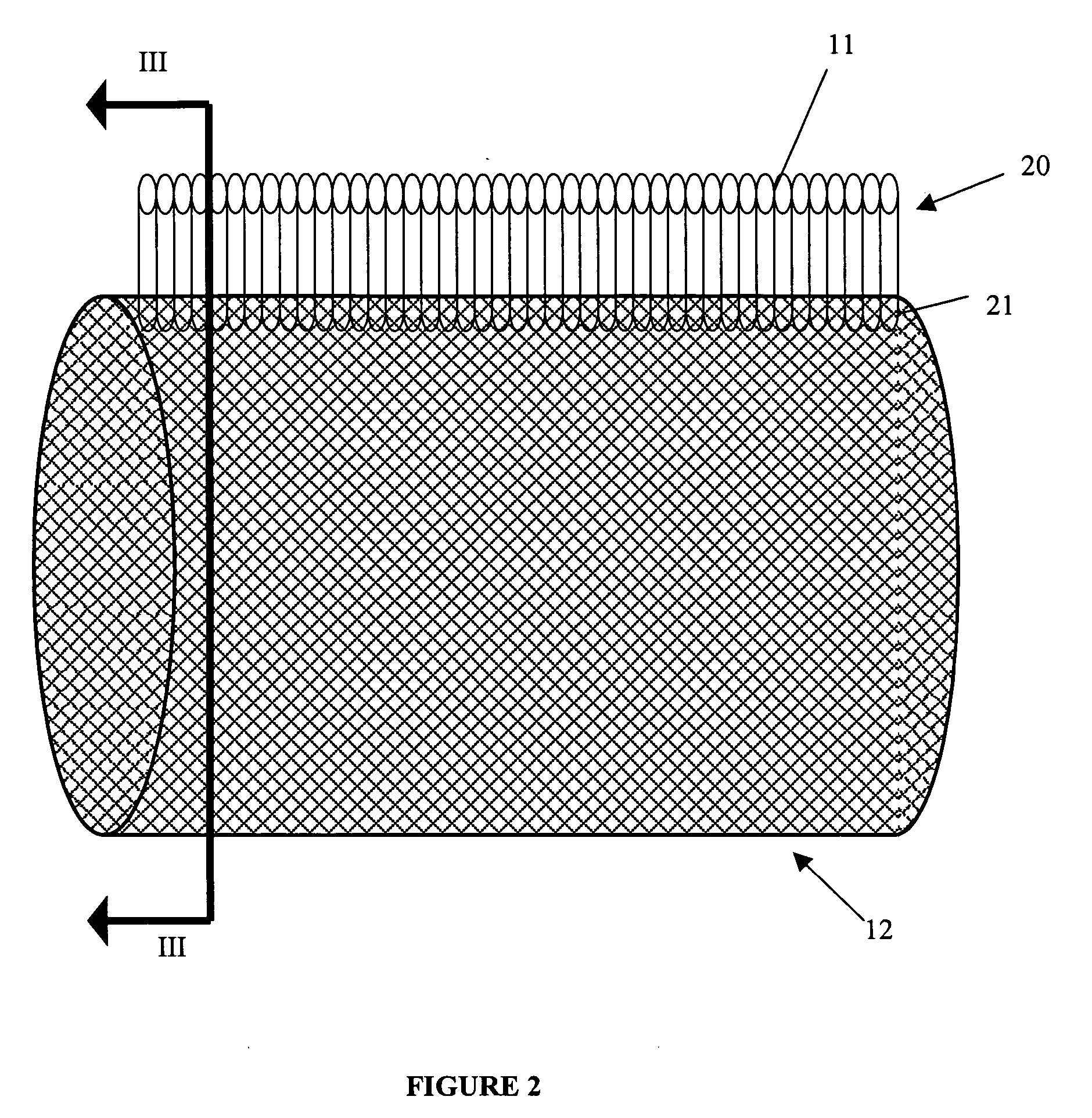

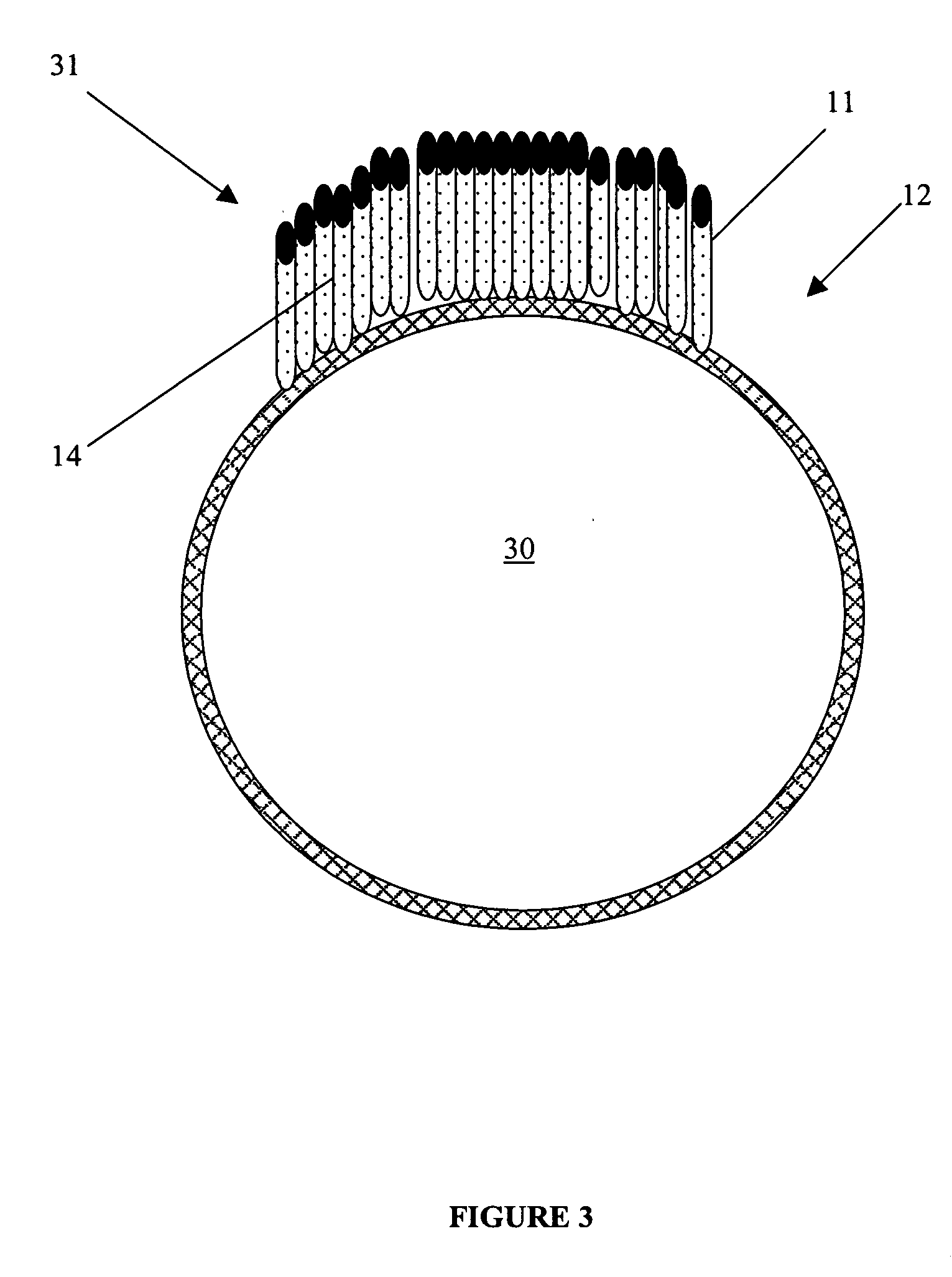

[0031] A nanoporous or mesoporous drug delivery coating or tissue engineering scaffold may be formed by the use of self-assembled cellular carbon nanotube foams (as a coating by itself) or may be blended in with another drug delivery carrier such as a polymer. The polymer may include polystrene, polyisobutylene copolymers, and / or styrene-isobutylene-styrene block copolymers such as styrene-isobutylene-styrene tert-block copolymers (SIBS). The incorporation of carbon nanotubes into the polymer may generate a nanoporous structure within the polymer drug delivery carrier.

[0032] Multi-walled carbon nanotube (MWNT) arrays may be assembled into contiguous cellular foams via the use of capillary forces that arise during the evaporation of liquids. For example, see the article “Capillarity-driven assembly of two-dimensional cellular nanotube foams” by Chakrapani et al, PNAS, Mar. 23, 2004, pages 4009-4012.

[0033] Nanotube foams may be formed in-situ in a coating formulation via the self-as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com