Ceramic sprayed member-cleaning method, program for implementing the method, storage medium storing the program, and ceramic sprayed member

a technology of ceramic sprayed member and cleaning method, which is applied in the direction of cleaning using liquids, superimposed coating process, liquid/solution decomposition chemical coating, etc., can solve the problems of abnormal film formation, lowering the operation rate of processing apparatus, and increasing the chamber size, etc., to achieve the effect of reliably suppressing the desorption and attachment of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will now be described in detail with reference to the drawings showing a preferred embodiment thereof.

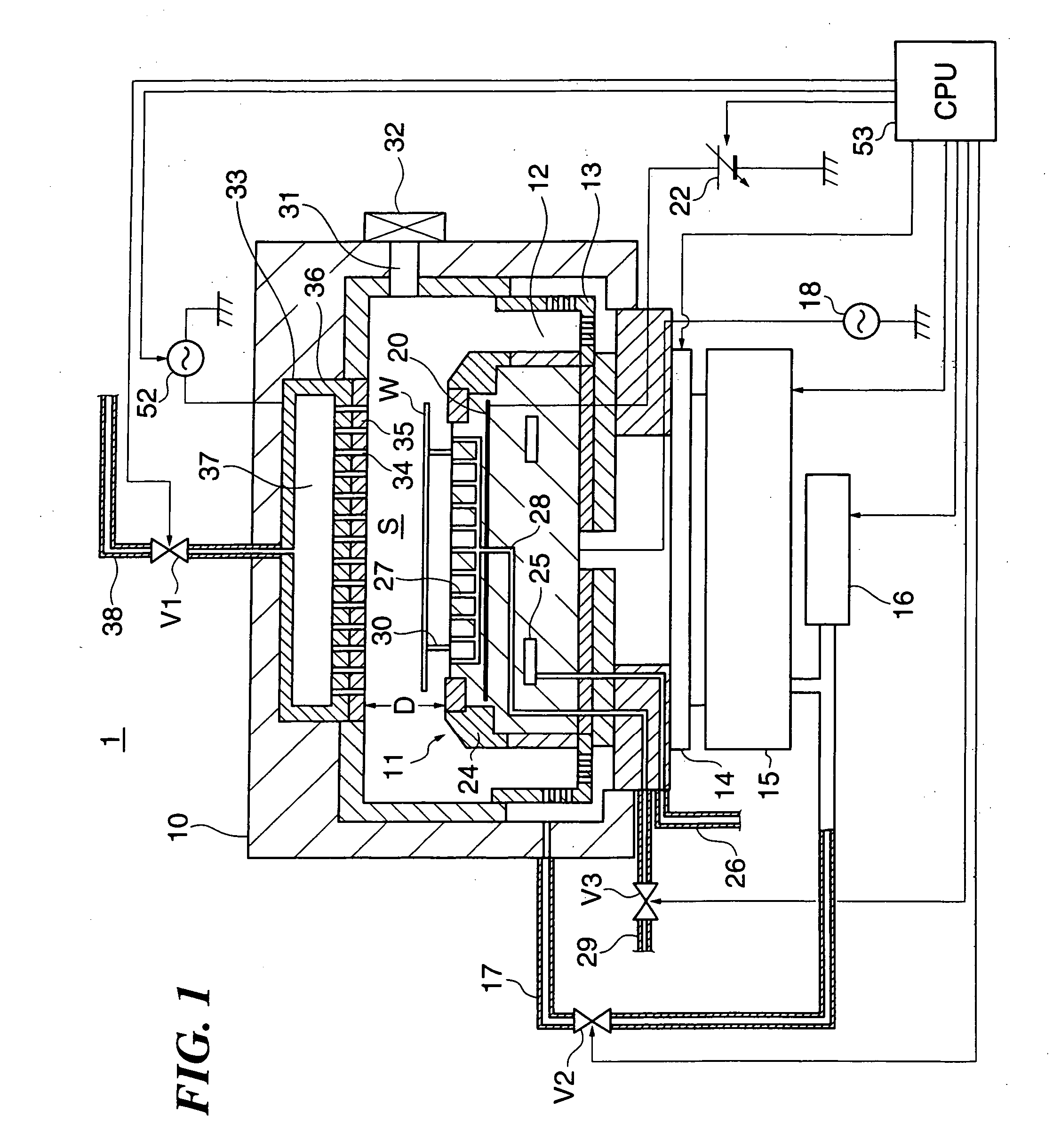

[0052]FIG. 1 is a cross-sectional view schematically showing the construction of a plasma processing apparatus in which is used a ceramic sprayed member according to an embodiment of the present invention.

[0053] Referring to FIG. 1, the plasma processing apparatus 1 as an etching apparatus for carrying out etching on wafers has formed therein a cylindrical chamber (processing chamber) 10 formed of metal, e.g. aluminum or stainless steel. Disposed within the chamber 10 is a cylindrical susceptor 11 on which is placed a wafer W having a diameter e.g. of 300 mm.

[0054] Formed between an inner side wall of the chamber 10 and the susceptor 11 is an exhaust passage 12 functioning as a flow path for discharging a gas above the susceptor 11 out of the chamber 10. An annular baffle plate 13 is disposed in an intermediate portion of the exhaust passage 12. A por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com