Methods and apparatus for drilling, completing and configuring U-tube boreholes

a technology for completing and drilling u-tubes, which is applied in the direction of borehole/well accessories, directional drilling, artificial islands, etc. it can solve the problems of affecting the environment, affecting the environment, and affecting the environment, and conventional above-ground pipelines are simply not acceptabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

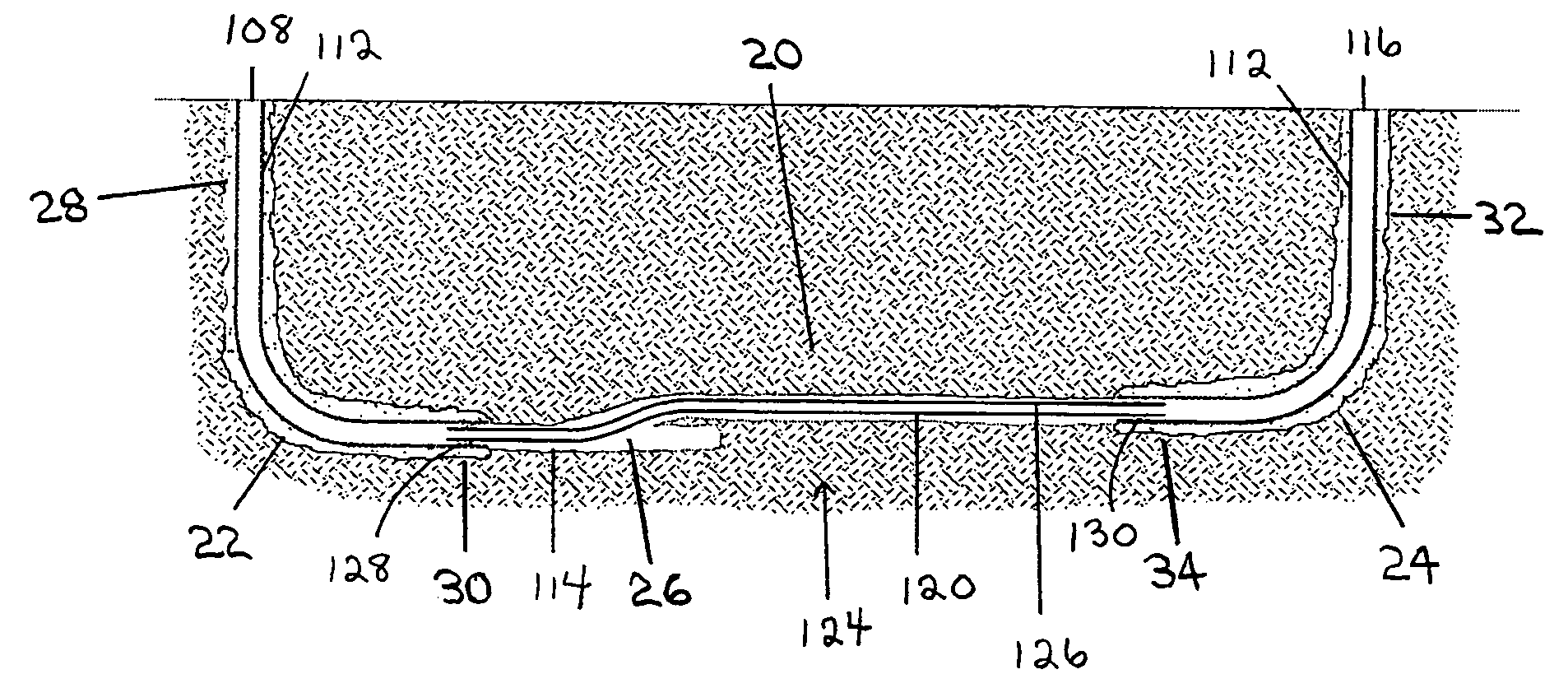

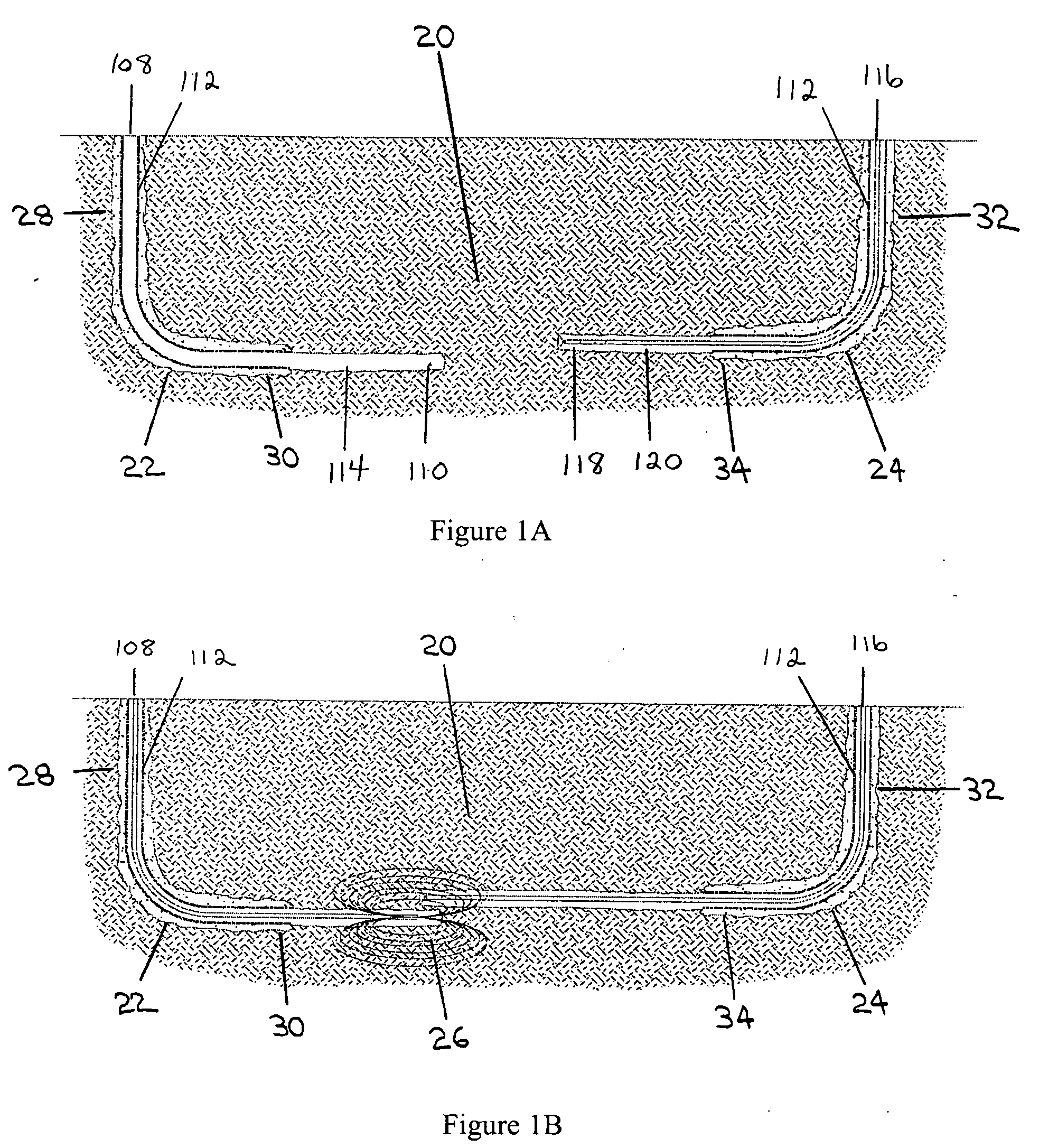

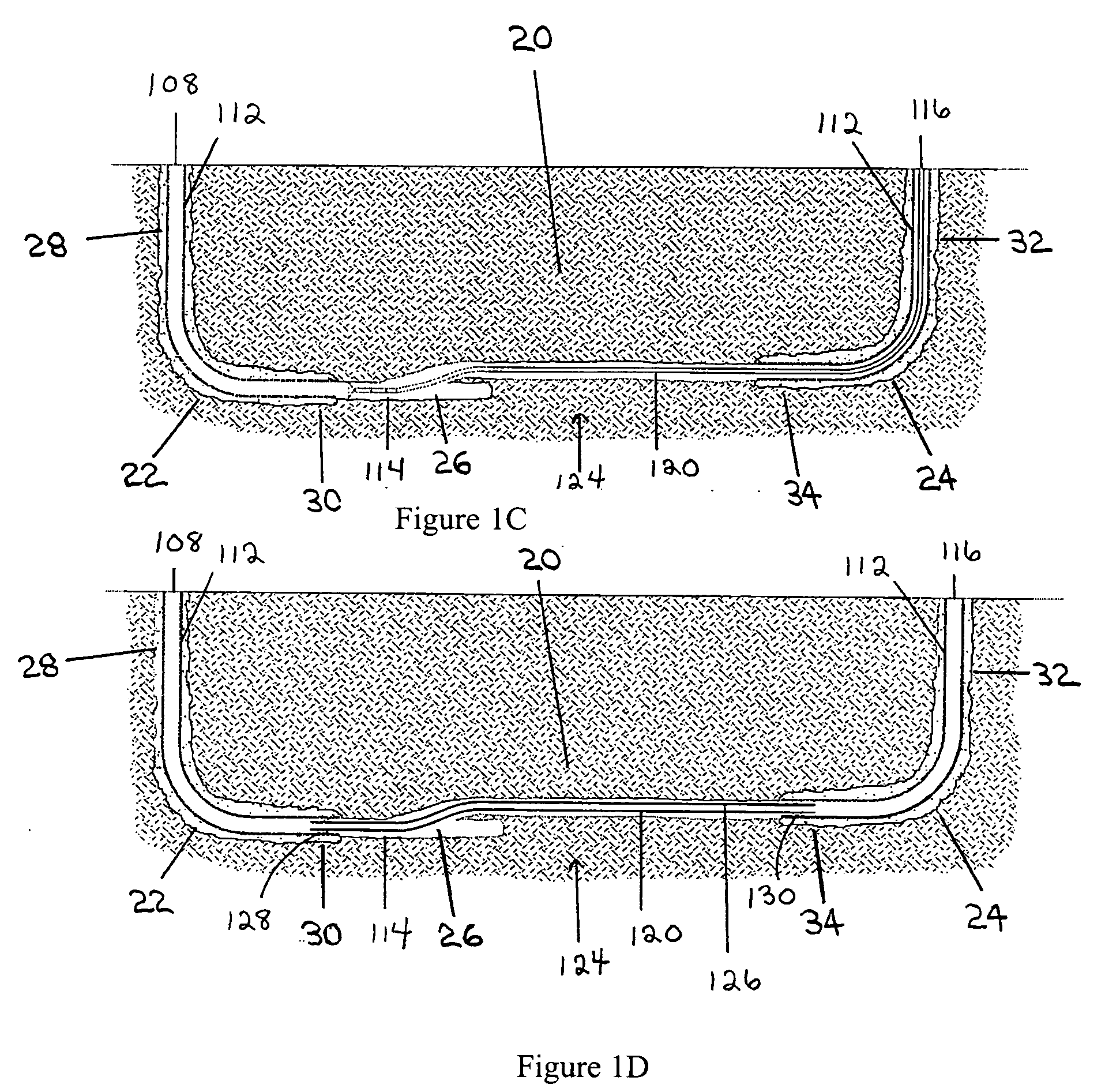

Drilling of a U-Tube Borehole Using an MGT Ranging System

Project Goals and Objectives

[0350] The goals of this project were laid out as follows: [0351] 1. Apply current directional drilling technology to see if two horizontal wellbores could be intersected end to end. Success was defined as intersecting the two wellbores with the drill bit, and being able to enter the wellbore of the second well with the drilling assembly. [0352] 2. Run standard steel casing through the intersection to prove that the two wellbores could be linked with solid tubulars. Success was defined as being able to run regular 7″ casing through an 8¾″ intersection point without getting the casing stuck in the hole. [0353] 3. Join the two casing strings with a connection technique that eliminated sand production. It was agreed that the connection technique used on this first well would be as simple as possible. If this initial trial was successful, future work could be done on a more advanced connection techniq...

example 2

Drilling of a U-Tube Borehole Using RMRS

[0411] This Example details the drilling of a pipeline comprising a U-tube borehole using RMRS as a magnetic ranging system. After months of drilling difficulties, and over 5900 meters of drilled borehole, the borehole intersection was achieved and successful fluid communication between the first borehole and the second borehole was established. A full drift junction between the first borehole and the second borehole was established to facilitate casing the U-tube borehole. Liner was run into both boreholes and placed 3 meters apart, with the liner covering the borehole intersection. Cementing the liner was performed by pumping down the annulus of one of the boreholes, and up the annulus of the other of the boreholes. Conventional drilling bottom hole assemblies were used to clean out the liner's float equipment before the rigs positioned at the surface locations of the two boreholes were moved off location so the well head could be tied into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com