Liquid composition, recording liquid, liquid catridge, liquid ejection cartridge, liquid ejection unit and method of liquid ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

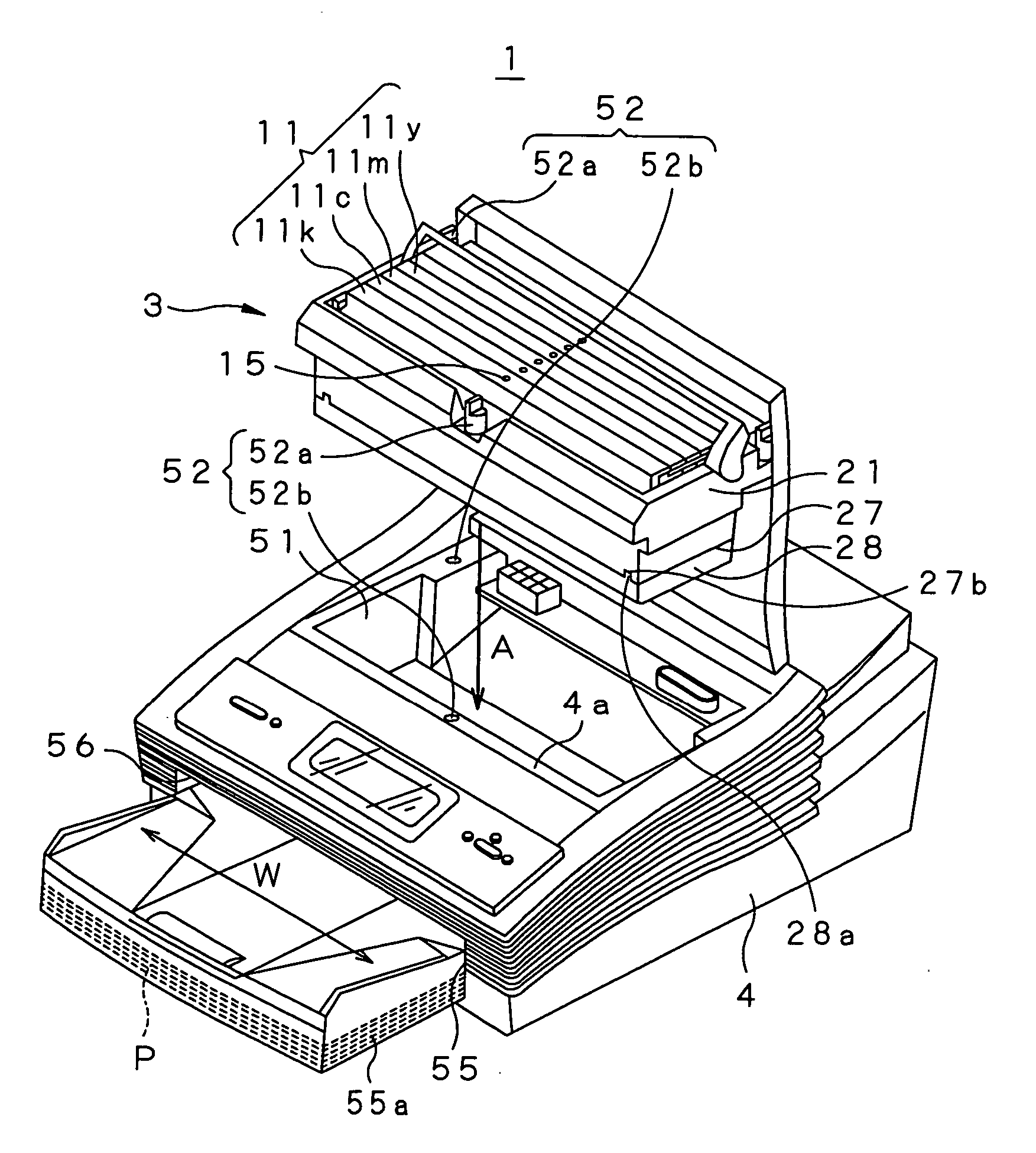

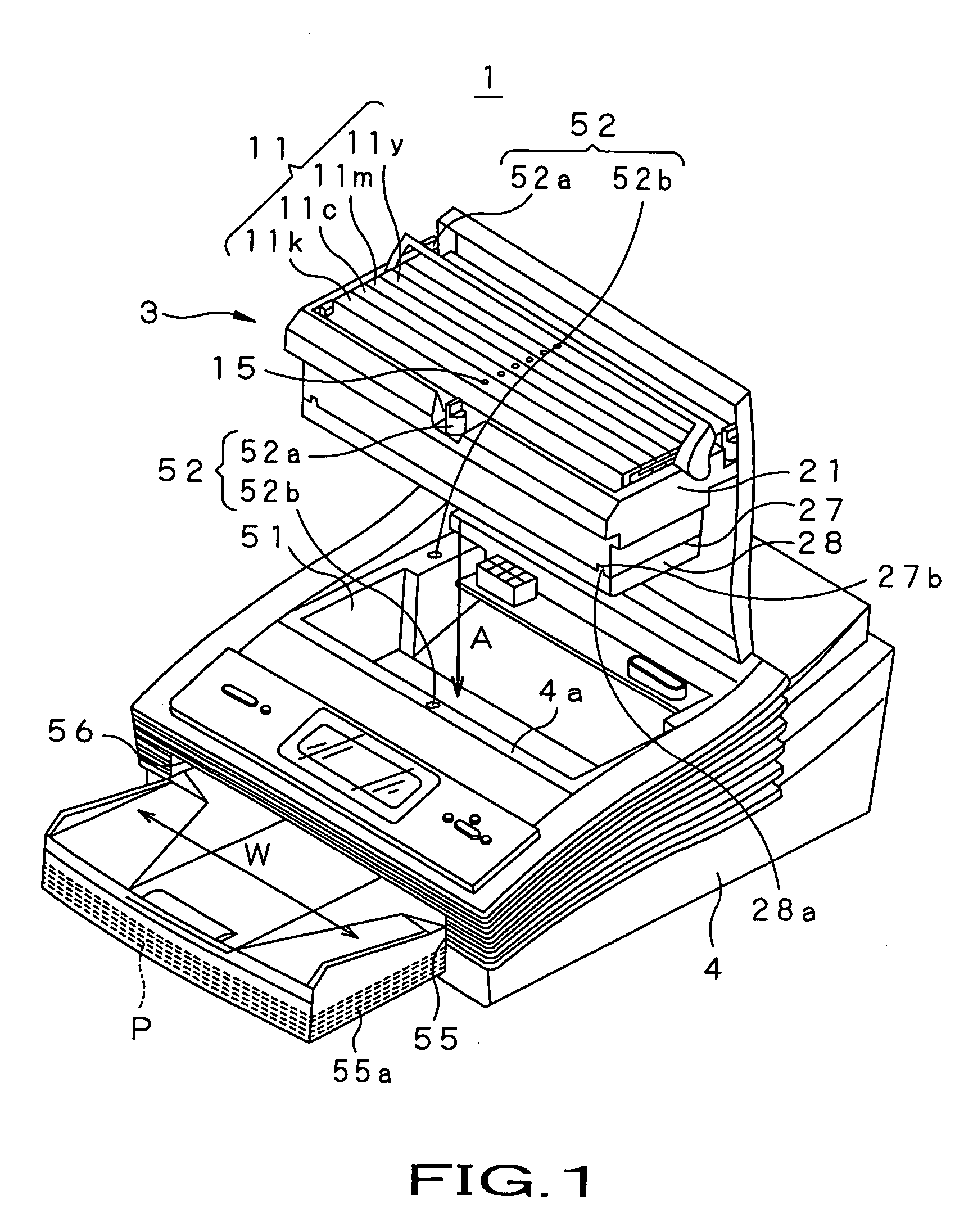

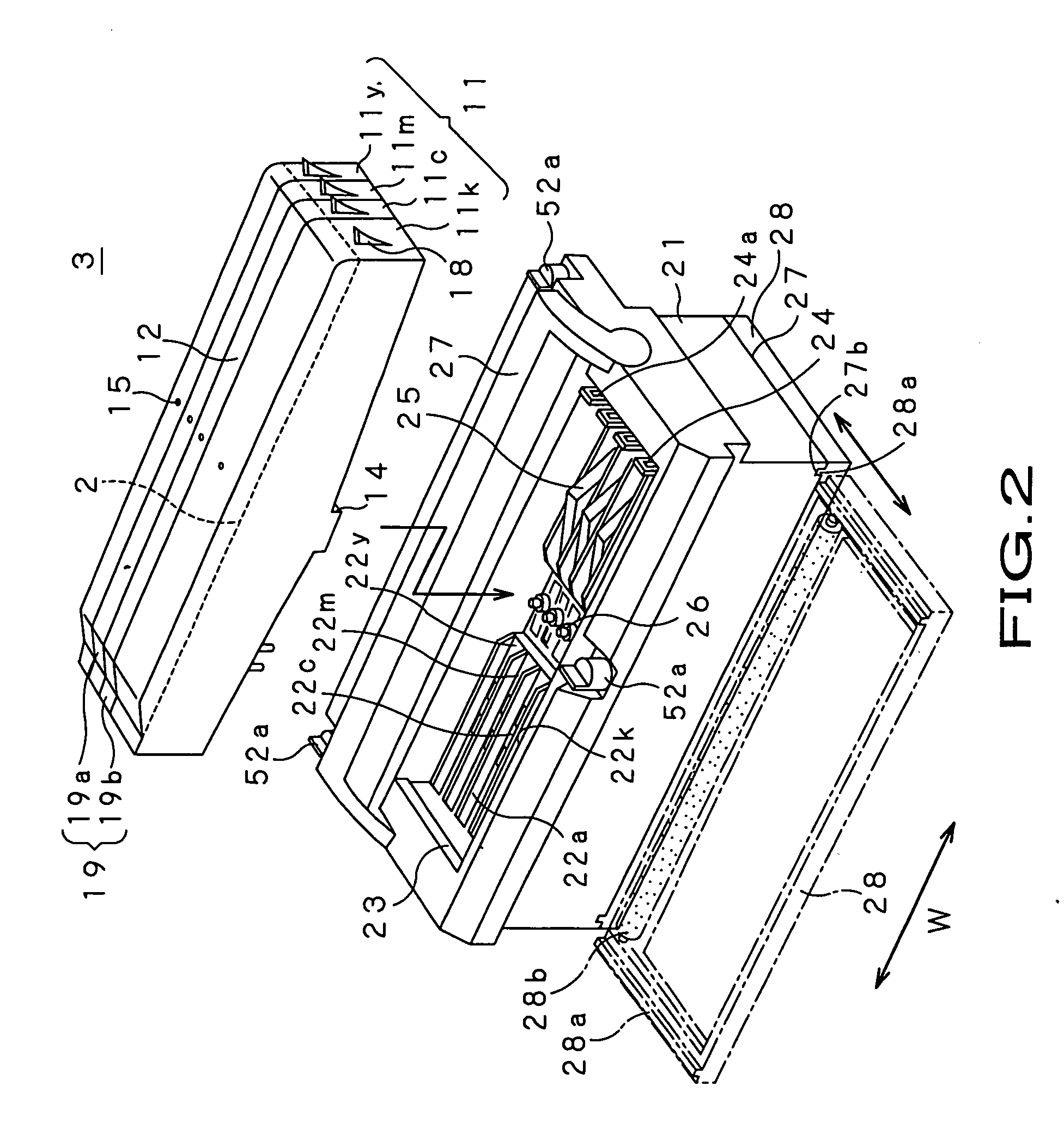

Image

Examples

examples

[0194] Samples of the ink actually prepared as the recording liquid according to the present invention will be described herebelow:

[0195] (Sample 1)

[0196] As Sample 1 of the recording liquid according to the present invention, yellow ink was prepared. For preparation of the yellow ink, 3 parts by weight of C.I. direct yellow 132 as the pigment which is the colorant of the ink, 76.7 parts by weight of water as the solvent, 10 parts by weight of 2-pyrrolidone as other solvent, 10 parts by weight of glycerin, 0.3 part by weight of acetylene glycol (SURFYNOL 465 by the Air Products) as surface active agent and an appropriate amount of triethanolamine as pH adjuster were mixed together and the ion antecedent was adjusted. Then, an appropriate amount of aluminum oxide was added to the mixture for the entire volume of the ink to contain 10 ppm of aluminum oxide (Al2O3) as hydrophobic colloid, thereby preparing neutral yellow ink of pH 7 in alkalinity.

[0197] (Sample 2)

[0198] As Sample 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Zeta potential | aaaaa | aaaaa |

| Hydrophobicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com