High strength rhenium alloys and high temperature components made from such alloys

a technology of rhenium alloys and high temperature components, which is applied in the direction of additive manufacturing, process efficiency improvement, and increasing energy efficiency, can solve the problems of short operational life of components, low ductility of commercial grade rhenium at high temperatures, and low boundary strength of bulk grain strength, so as to achieve the effect of higher oxygen affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following detailed description of the invention is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background of the invention or the following detailed description of the invention.

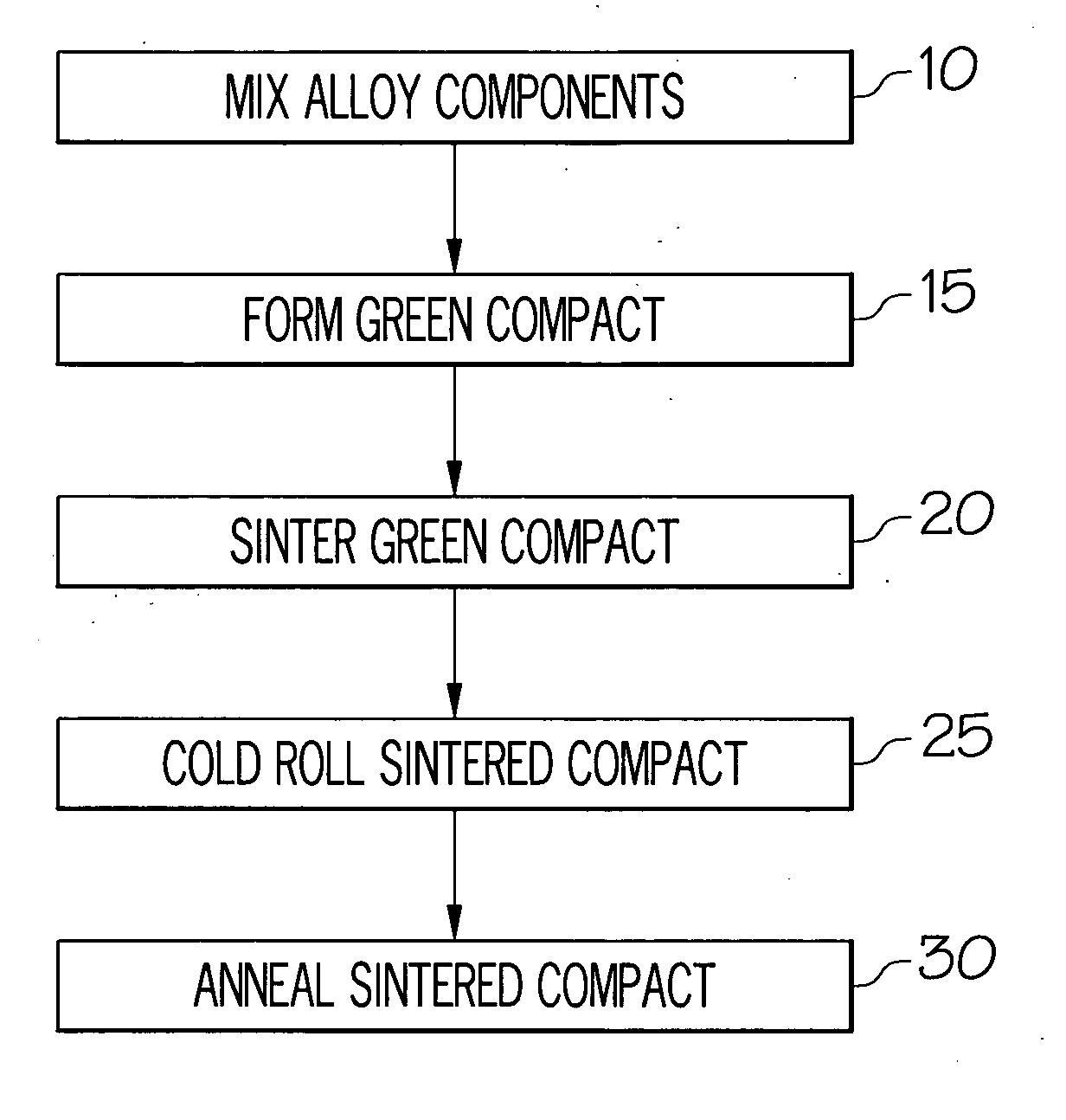

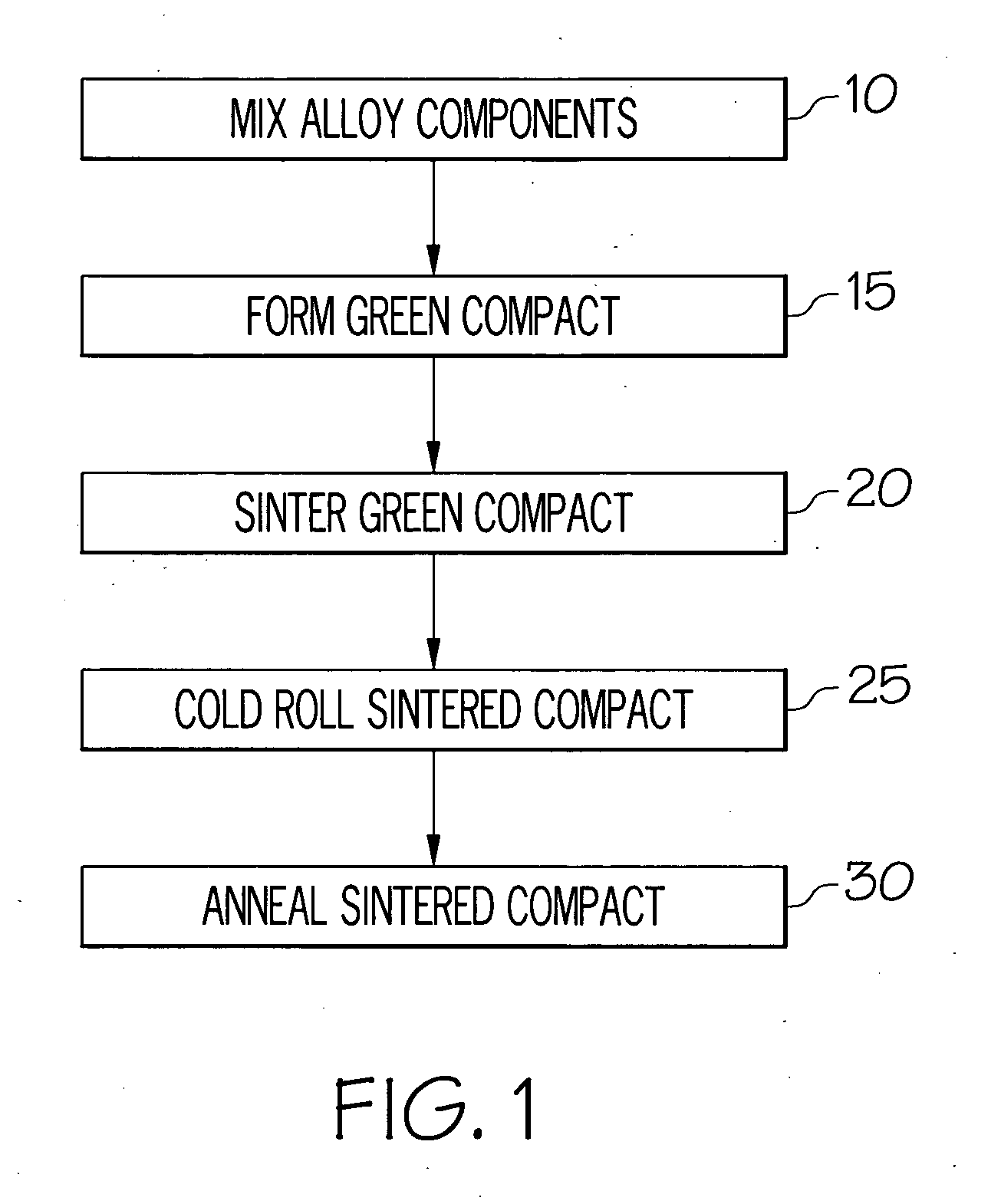

[0013] The refractory alloys of the present invention can be made using a variety of processes including but not limited to powder metallurgy fabrication methods, solid free-form fabrication methods, and casting methods. These and other methods can be used to simply cause the individual alloy components to diffuse and react to form an alloy, or alternatively they can be used to produce a component having a predetermined shape and predetermined dimensions from the alloy.

[0014] The term solid free-form fabrication (SFFF) is a designation for a group of processes that produce components in their three dimensional shapes from additive formati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com