A kind of ti doped with rare earth metal 4 o 7 Electrode preparation method

A technology of rare earth metals and rare earth metal salts, applied in the field of electrochemistry, can solve problems such as weak ability to produce OH and limited electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

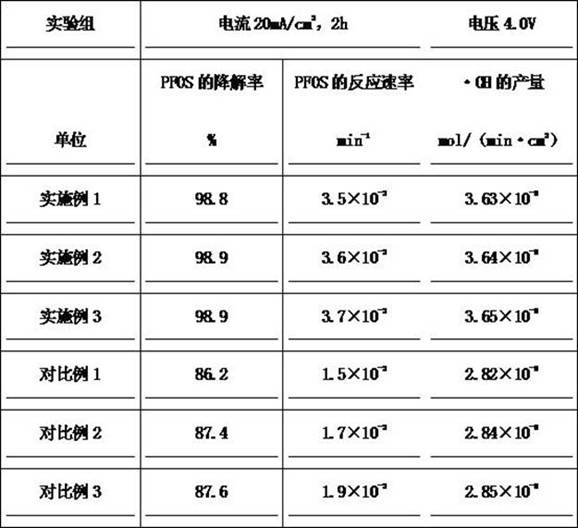

Examples

Embodiment 1

[0037] A kind of Ti doped with rare earth metal 4 o 7 The preparation method of electrode, concrete steps are as follows,

[0038] S1, Ti 4 o 7 Preparation of powder:

[0039] TiO 2 Grind into powder, add polyvinyl alcohol, stir, and carry out high-temperature reduction after stirring evenly, introduce hydrogen and argon, heat and pressurize, the temperature is 1000°C, and the reaction time is 1h. During the reaction, polyvinyl alcohol is recovered, and after the reaction is completed , cooled and ground to obtain Ti 4 o 7 powder;

[0040] S2, the treatment of polyvinyl alcohol:

[0041] At room temperature, add sodium dodecylbenzenesulfonate, cetyltrimethylammonium bromide, and deionized water to the recovered polyvinyl alcohol, stir evenly, add butyraldehyde and acid solution, cool down, and The temperature is 8°C, the reaction time is 1h, and after the reaction, the pH is adjusted to be alkaline to obtain the auxiliary agent;

[0042] S3, the preparation of electr...

Embodiment 2

[0051] A kind of Ti doped with rare earth metal 4 o 7 The preparation method of electrode, concrete steps are as follows,

[0052] S1, Ti 4 o 7 Preparation of powder:

[0053] TiO 2 Grind into powder, add polyvinyl alcohol, stir, and then carry out high-temperature reduction after stirring evenly, introduce hydrogen and argon, heat and pressurize, the temperature is 1050°C, the reaction time is 1.3h, recover polyvinyl alcohol during the reaction, and wait for the reaction to end After that, the temperature was lowered and ground to obtain Ti 4 o 7 powder;

[0054] S2, the treatment of polyvinyl alcohol:

[0055] At room temperature, add sodium dodecylbenzenesulfonate, cetyltrimethylammonium bromide, and deionized water to the recovered polyvinyl alcohol, stir evenly, add butyraldehyde and acid solution, cool down, and The temperature is 9°C, the reaction time is 1.3h, and after the reaction, the pH is adjusted to be alkaline to obtain the auxiliary agent;

[0056] S3...

Embodiment 3

[0065] A kind of Ti doped with rare earth metal 4 o 7 The preparation method of electrode, concrete steps are as follows,

[0066] S1, Ti 4 o 7 Preparation of powder:

[0067] TiO 2 Grind into powder, add polyvinyl alcohol, stir, stir evenly, carry out high-temperature reduction, feed hydrogen and argon, heat and pressurize, the temperature is 1100 ° C, the reaction time is 1.5h, recover polyvinyl alcohol during the reaction, and wait for the reaction to end After that, the temperature was lowered and ground to obtain Ti 4 o 7 powder;

[0068] S2, the treatment of polyvinyl alcohol:

[0069] At room temperature, add sodium dodecylbenzenesulfonate, cetyltrimethylammonium bromide, and deionized water to the recovered polyvinyl alcohol, stir evenly, add butyraldehyde and acid solution, cool down, and The temperature is 10°C, the reaction time is 1.5h, and after the reaction, the pH is adjusted to be alkaline to obtain the auxiliary agent;

[0070] S3, the preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com