Novel steel-making composite deoxidizer and preparation method thereof

A composite deoxidizer and a new type of technology, applied in the field of metallurgy and metal processing, can solve the problems of difficulty in forming large liquid particles with low melting point, destroying the mechanical properties of steel, and difficulty in deoxidizing products, and achieves good deoxidization effect and oxygen-friendly performance. The effect of increasing and decreasing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

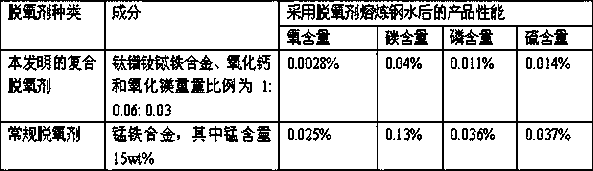

Embodiment 1

[0022] Prepare deoxidizer.

[0023] (1) Manganese content is 14 wt%, silicon content is 3 wt%, aluminum content is 5 wt%, titanium content is 2 wt%, praseodymium content is 1 wt%, neodymium content is 1 wt%, terbium The content of the metal is 0.5wt%, and the rest is the ratio of iron to weigh the metal raw material. In the present embodiment, the total weight of the metal raw material can be 10Kg, 20Kg or 25Kg.

[0024] (2) The metal raw materials are made into powder by mechanical method, and the size of the powder particles is not greater than 0.8mm.

[0025] (3) Fully physically mix the powdered various metal raw materials at room temperature.

[0026] (4) The mixed raw materials are in high vacuum 1×10 -3 Under the condition of mm Hg, it was smelted at 1250°C for 150 minutes, and then cast into shape.

[0027] (5) Put the poured alloy into the holding furnace, control the temperature at 520°C and keep it warm.

[0028] (6) Introduce a hydrogen-argon mixed atmosphere i...

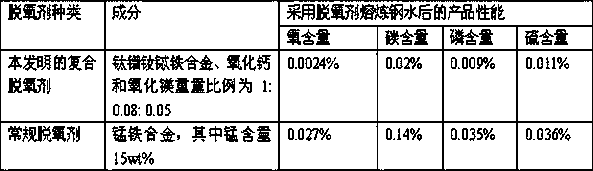

Embodiment 2

[0038] Prepare deoxidizer.

[0039] (1) Manganese content is 16wt%, silicon content is 5wt%, aluminum content is 7wt%, titanium content is 4wt%, praseodymium content is 6wt%, neodymium content is 4wt%, terbium The content of the metal is 1wt%, and the rest is the ratio of iron to weigh the metal raw material. In this embodiment, the total weight of the metal raw material can be 15Kg, 25Kg or 30Kg.

[0040] (2) The metal raw materials are made into powder by mechanical method, and the size of the powder particles is not greater than 0.9mm.

[0041] (3) Fully physically mix the powdered various metal raw materials at room temperature.

[0042] (4) The mixed raw materials are in high vacuum 1×10 -6 Under the condition of mm Hg, it was smelted at 1350°C for 150 minutes, and then cast into shape.

[0043] (5) Put the poured alloy into the holding furnace, control the temperature at 650°C and keep it warm.

[0044] (6) Introduce a hydrogen-argon mixed atmosphere into the holding...

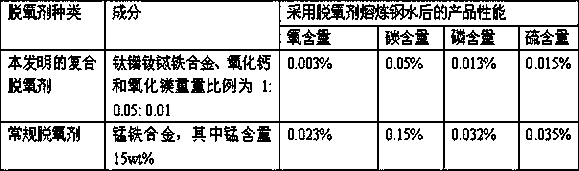

Embodiment 3

[0054] Prepare deoxidizer.

[0055] (1) Manganese content is 15wt%, silicon content is 4wt%, aluminum content is 6wt%, titanium content is 3wt%, praseodymium content is 3wt%, neodymium content is 2wt%, terbium The content of the metal is 0.8wt%, and the rest is the ratio of iron to take the metal raw material. In the present embodiment, the total weight of the metal raw material can be 12Kg, 18Kg or 27Kg.

[0056] (2) The metal raw materials are made into powder by mechanical method, and the size of the powder particles is not greater than 0.85mm.

[0057] (3) Fully physically mix the powdered various metal raw materials at room temperature.

[0058] (4) The mixed raw materials are in high vacuum 1×10 -4 Under the condition of mm Hg, it was smelted at 1290°C for 130 minutes, and then cast into shape.

[0059] (5) Put the poured alloy into the holding furnace, control the temperature at 620°C and keep it warm.

[0060] (6) Introduce a hydrogen-argon mixed atmosphere into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com