Light emitting device and method of making the same

a light emitting device and wavelength conversion technology, which is applied in the direction of solid-state devices, semiconductor devices for light sources, lighting and heating apparatus, etc., can solve the problems of difficult to secure long-term reliability, low brightness of light emitting devices, and complicated manufacturing processes, so as to enhance sealing properties and reliability, the effect of suppressing the deterioration caused by light emitted from the light emitting element and stable brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

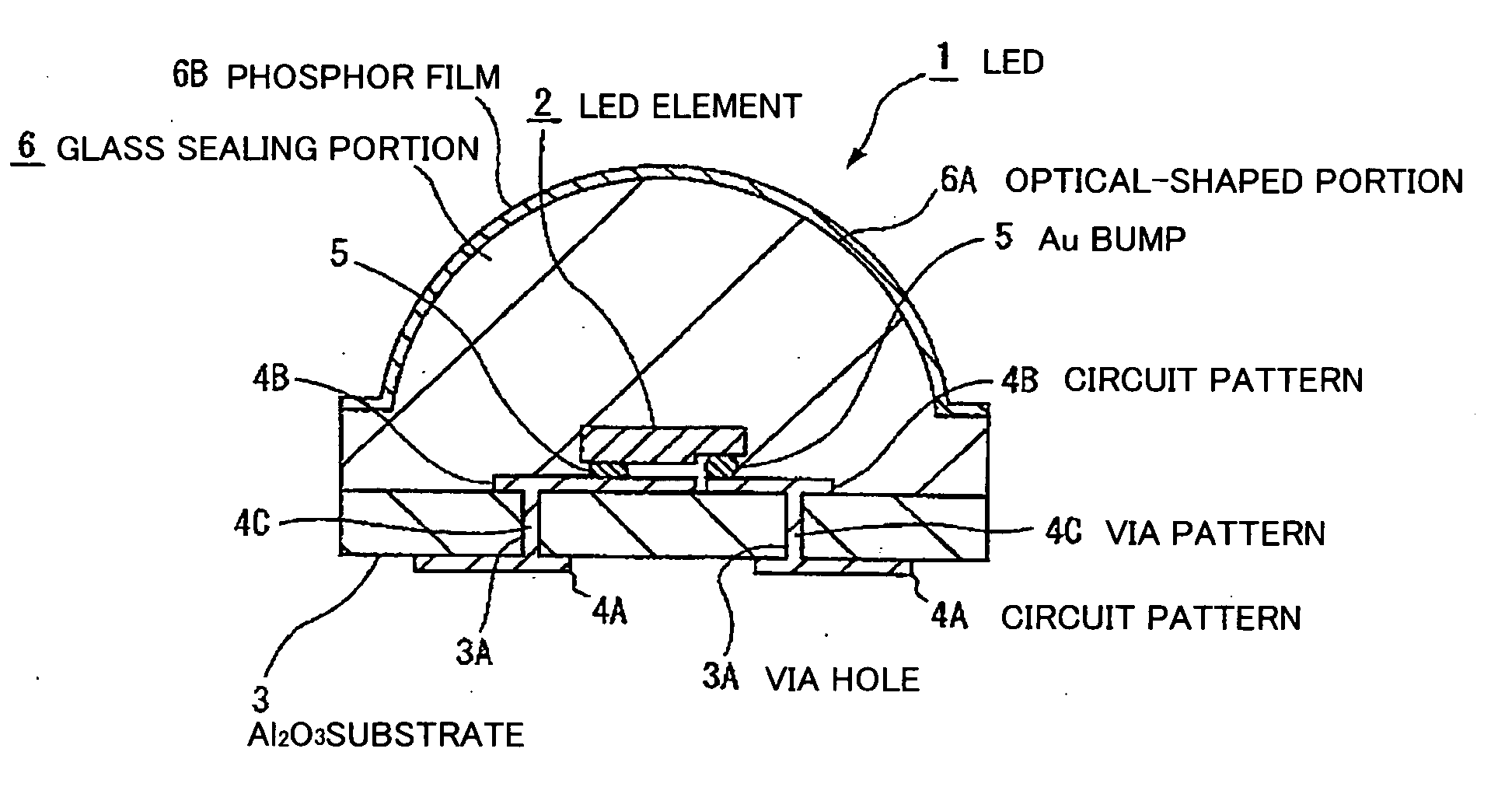

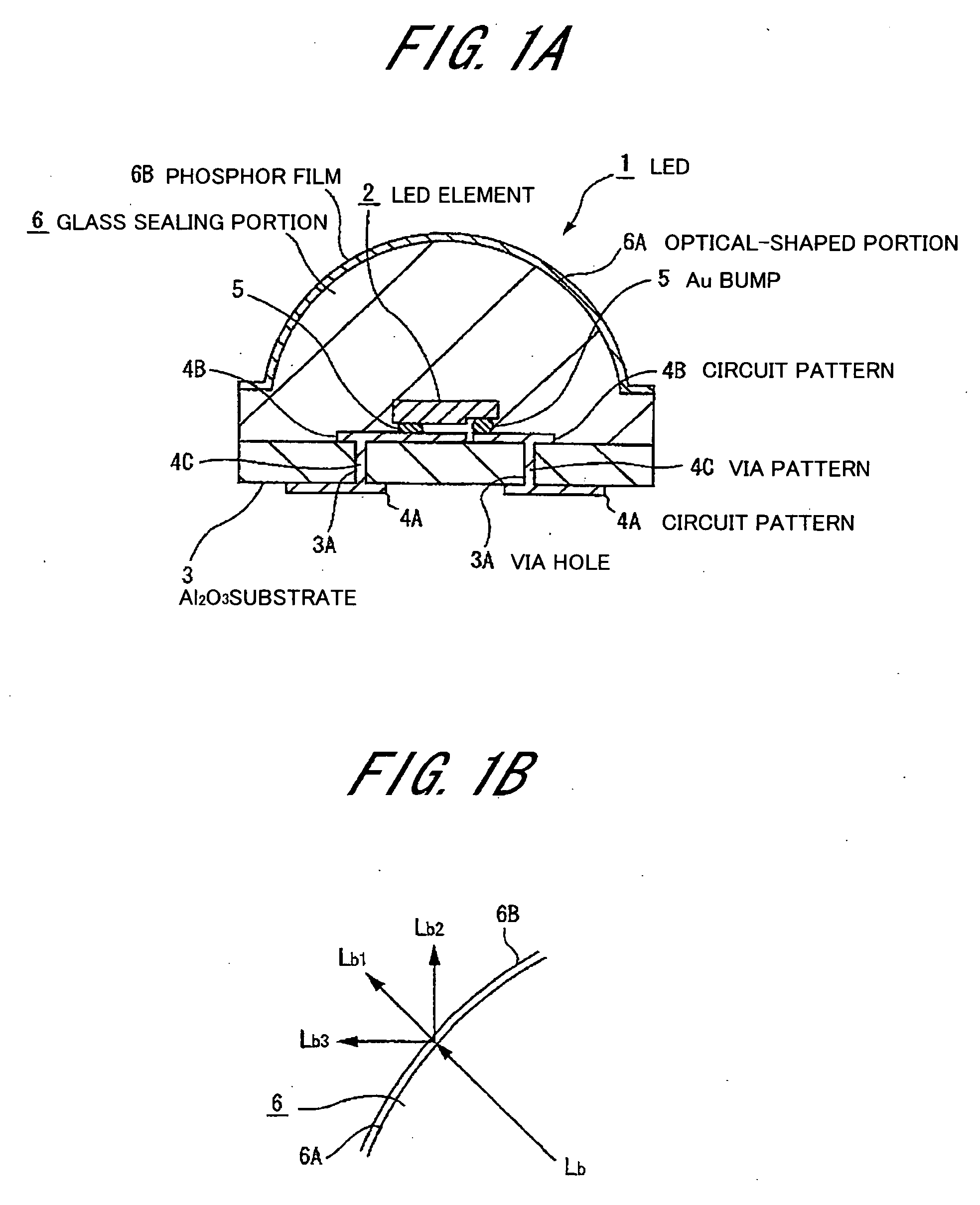

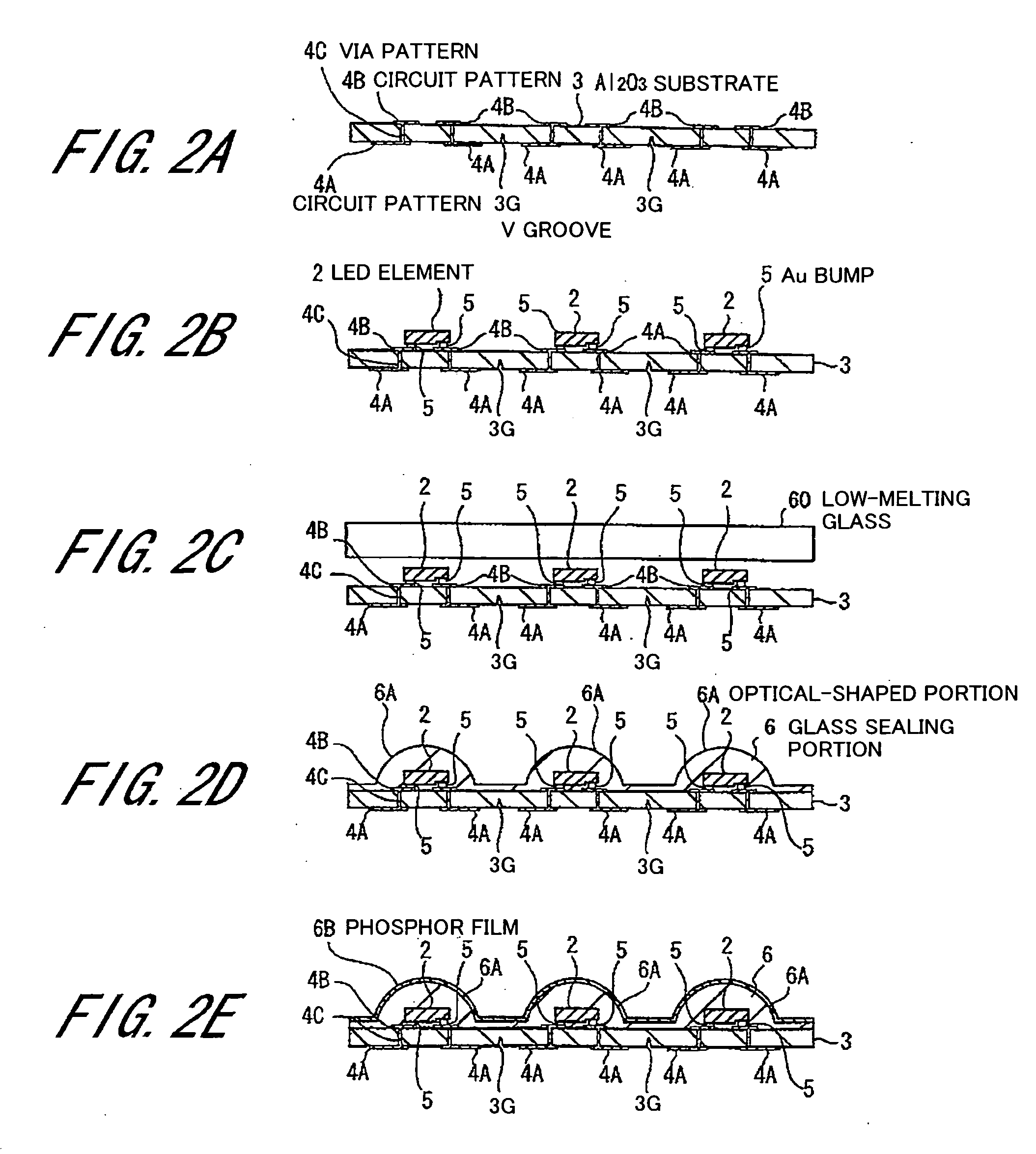

[0097]FIG. 1A is a cross sectional view showing a light emitting device in the first preferred embodiment according to the invention. FIG. 1B is a schematic diagram illustrating light radiation on the surface of a glass sealing portion.

Components of the Device

[0098] As shown in FIG. 1A, the LED 1 comprises: a flip-chip type LED element 2; an Al2O3 substrate 3, as an inorganic material substrate, provided with circuit patterns 4A, 4B, and via holes 3A; an Au bump 5 to electrically connect between the circuit pattern 4B and an electrode of the LED element 2; and a glass sealing portion 6 that is made of an inorganic sealing material to seal the Al2O3 substrate 3 and the LED element 2 and is provided with an optical-shaped portion 6A formed semispherical.

(Details of the Components)

[0099] The LED element 2 comprises, sequentially grown on an underlying sapphire substrate, an AlN buffer layer and a GaN-based semiconductor layer including an n-GaN layer, a light-emitting layer, and ...

second embodiment

[0128]FIG. 3 is a cross sectional view showing a light emitting device in the second preferred embodiment according to the invention. Hereinafter, like components are indicated by the same numerals used in the first embodiment.

(Components of the Device)

[0129] The LED 1 of the second embodiment is different from that of the first embodiment in that a phosphor-containing glass layer 6C is used in place of the phosphor film 6B of the first embodiment.

(Details of the Components)

[0130] The phosphor-containing glass layer 6C is made of a mixture material (with a melting point of about 300° C.) that a phosphor particle with an average outside diameter of 10 μm is mixed with a fluoride low-melting glass particle with an average outside diameter of 10 μm. The phosphor-containing glass layer 6C is formed integrally on the surface of the glass sealing portion 6 with the optical-shaped portion 6A by conducting the electrostatic coating of the mixture material while heating the glass seali...

third embodiment

[0133]FIG. 4 is a cross sectional view showing a light emitting device in the third preferred embodiment according to the invention.

(Components of the Device)

[0134] The LED 1 of the third embodiment is different from that of the first embodiment in that a dichroic mirror 6D is formed between the glass sealing portion 6 and the phosphor film 6B such that it prevents the re-entering of light radiated from the phosphor to the glass sealing portion 6.

(Details of the Components)

[0135] The dichroic mirror 6D is formed by laminating alternately TiO2 film and SiO2 film and severs to transmit light of less than 500 nm and to reflect light of more than 500 nm. Thus, the dichroic mirror 6D can transmit blue light of 470 nm emitted from the LED element 2 and reflect yellow light radiated from the phosphor of the phosphor film 6B to prevent the re-entering thereof to the glass sealing portion 6.

Effects of the Third Embodiment

[0136] In the third embodiment, the brightness can be enhanced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com