Fluid delivery systems, devices and methods for delivery of fluids

a technology of fluid delivery system and fluid delivery method, which is applied in the field of fluid delivery system, can solve the problems of high cost of contrast, time-consuming and laborious reloading of syringes, and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

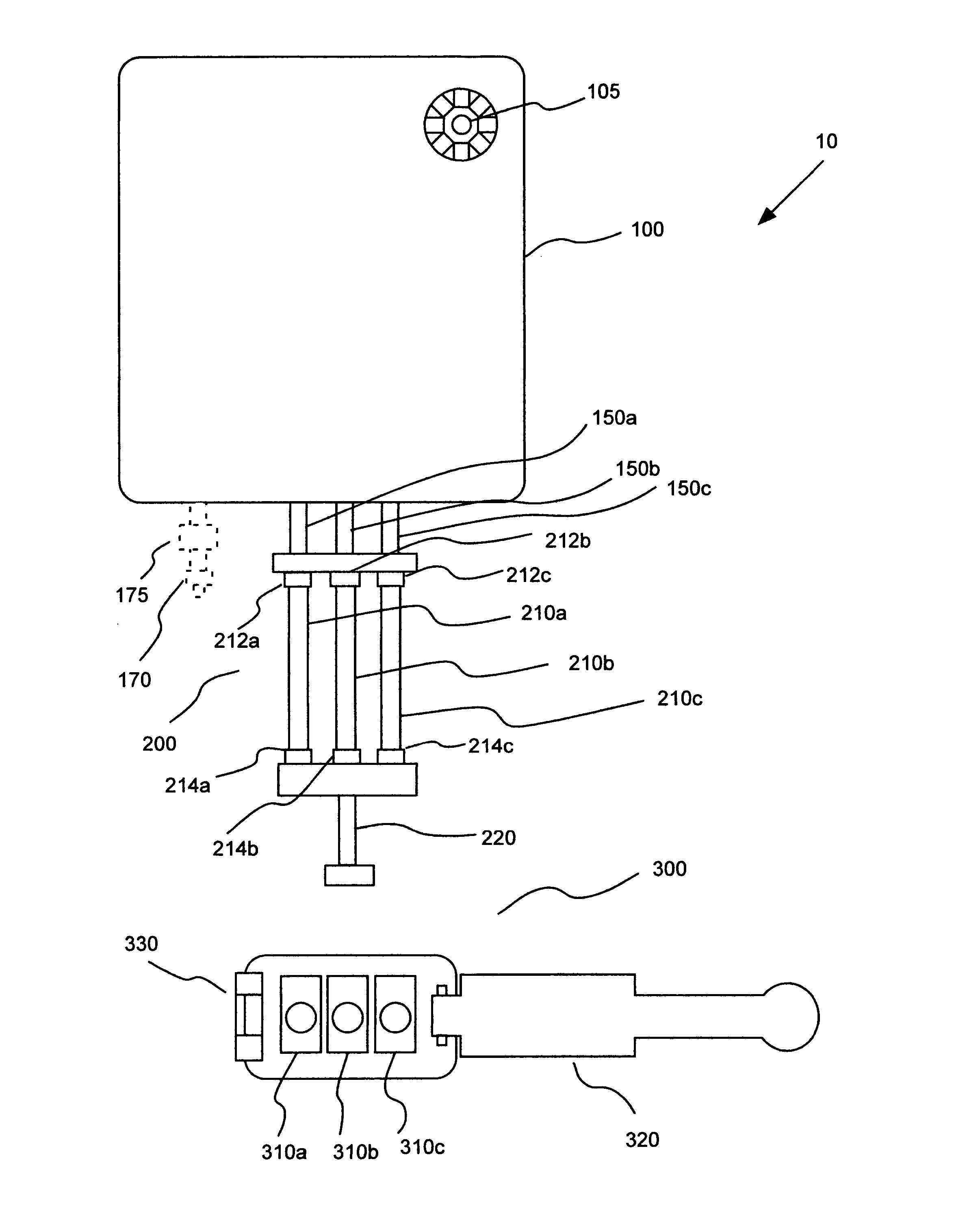

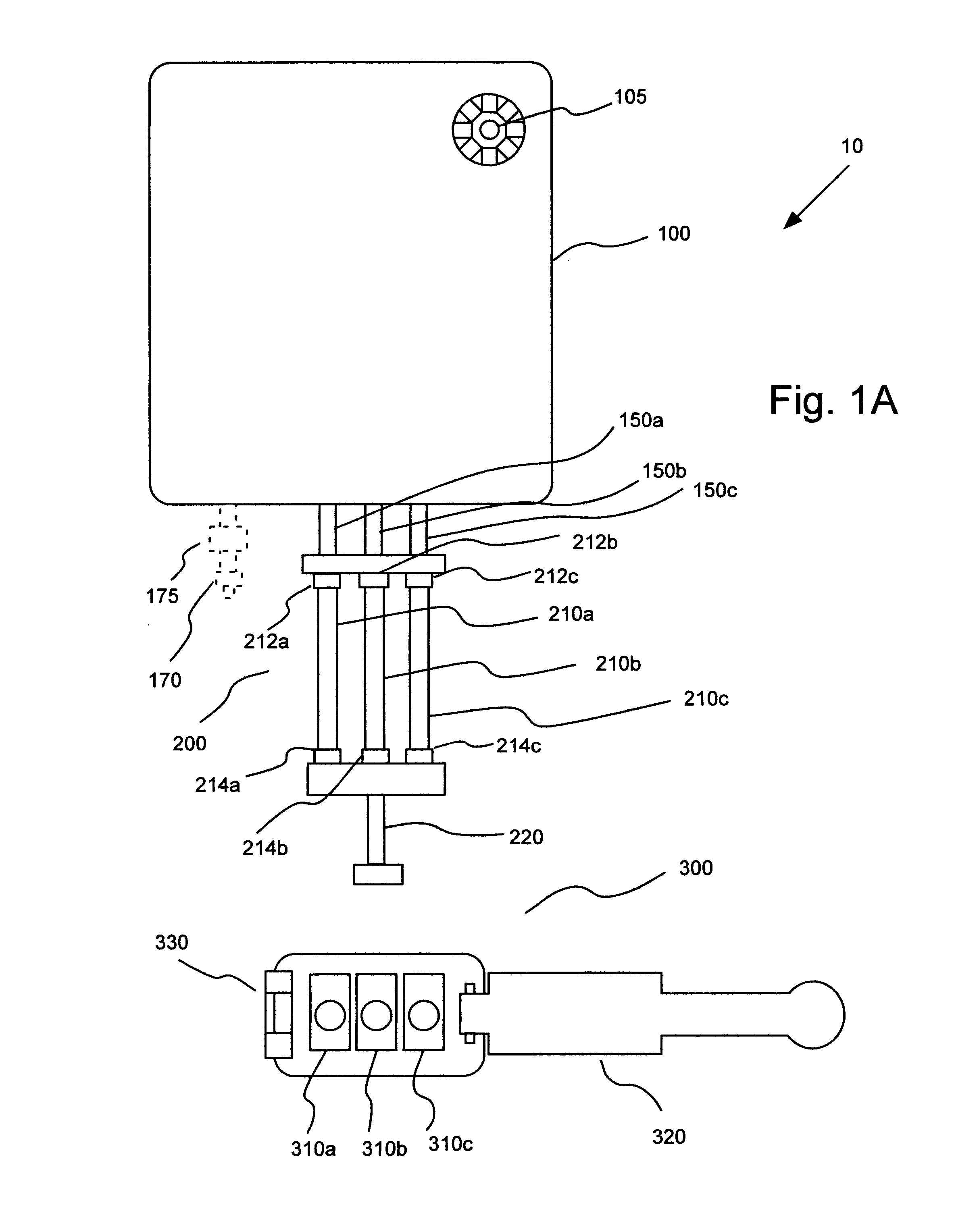

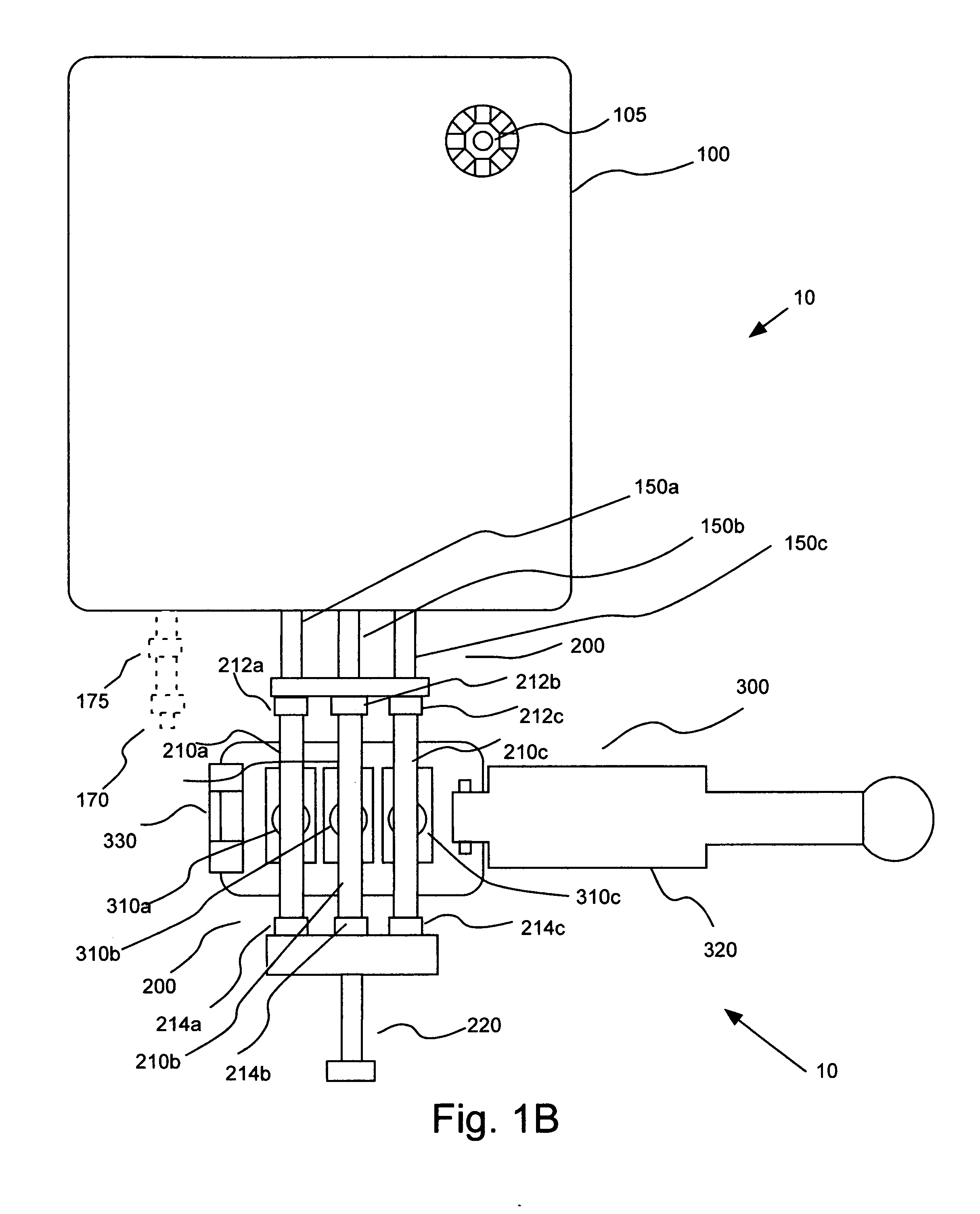

[0054] In general, the present invention provides fluid delivery systems that can be used to inject one or more fluids into one or more patients. FIGS. 1A through 1D illustrate an embodiment of a fluid delivery system 10 of the present invention in which a fluid container 100 is in operative connection with a continuous pressurizing mechanism 200 including multiple pressurizing chambers. In the embodiment of FIGS. 1A through 1C, pressurizing mechanism 200 includes three pressurizing chambers 210a, 210b and 210c. System 10 further includes an actuator or drive mechanism 300, which operates in connection with pressurizing mechanism 200 to pump fluid from within fluid container 100.

[0055] In one embodiment, each of pressurizing chambers 210a, 210b and 210c is formed from a flexible, resilient material such as a resilient polymeric material (for example, silicone polymer materials, urethane polymer materials and vinyl polymer materials). Drive mechanism 300 includes drive members 310a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com