Capsular intraocular lens implant having a refractive liquid therein

a technology of intraocular lens and liquid refractive lens, which is applied in the field of accommodating intraocular lens implants, can solve the problems of affecting the ability of the eye to properly focus an image upon the retina, increasing the focal length of the eye, and unable to achieve the ability, so as to achieve safe and effective treatment and safe long-term use of the eye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

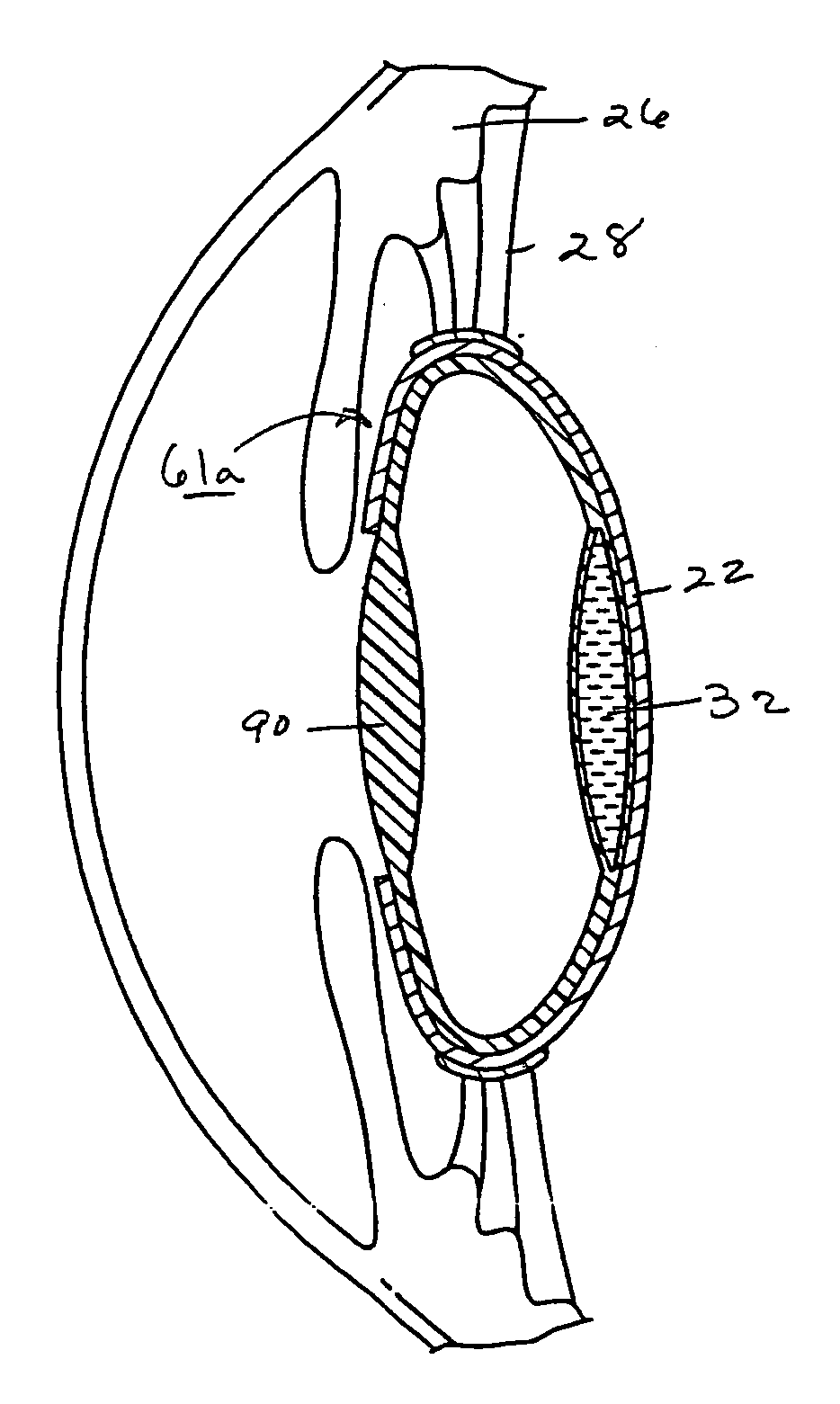

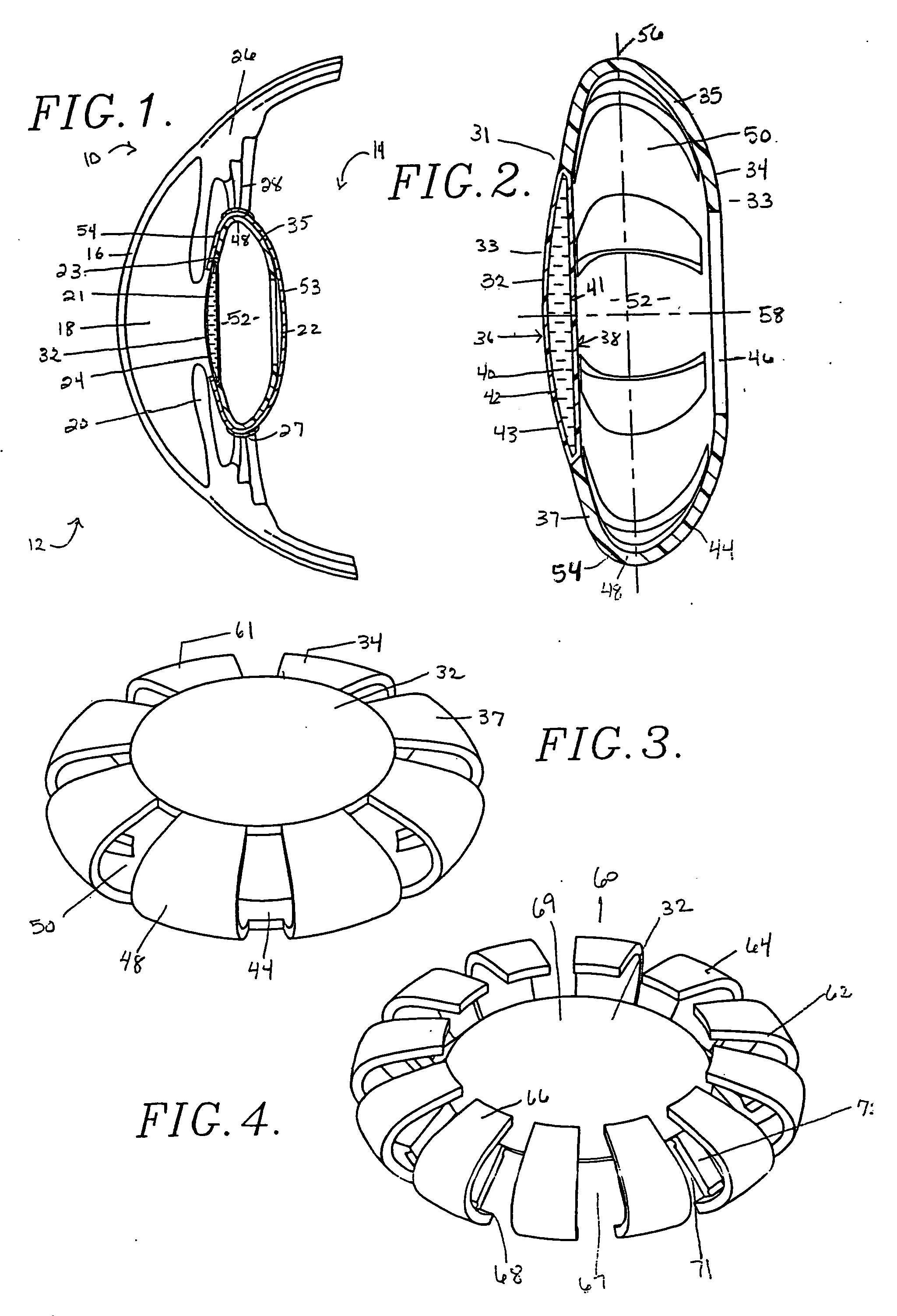

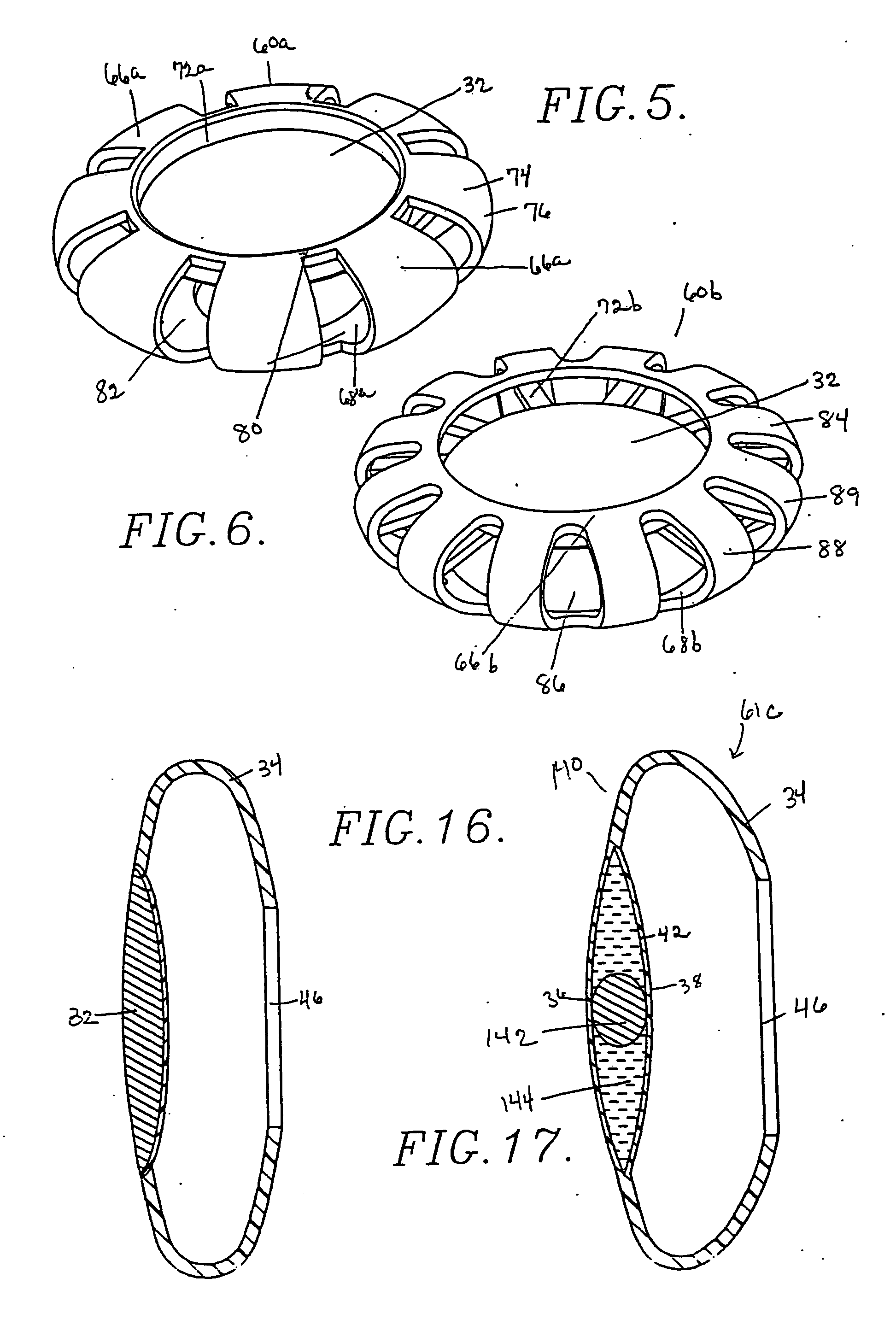

[0043] Referring now to the drawings, the present invention is in the form of an IOL for surgical replacement of the natural crystalline lens in the treatment of refractive error in the human eye. FIG. 1 shows the various components of the human eye 10 pertinent to this invention. Briefly, the eye 10 includes an anterior portion 12 and a posterior portion 14. The anterior portion 12 of the eye 10 is covered by a cornea 16 which encloses and forms an anterior chamber 18. The anterior chamber 18 contains aqueous fluid and is bounded at the rear by an iris 20. The iris 20 opens and closes to admit appropriate quantities of light into the inner portions of the eye 10. The eye 10 also includes a capsule 22 which ordinarily contains the natural crystalline lens (which would be located at numeral 24 in the natural, unmodified eye). The eye 10 includes a ciliary muscle or body 26 having zonular fibers 28 (also referred to as zonules) which are attached to the eye 10. The vitreous humor 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com