Synthetic fiber rope for an elevator

a technology of synthetic fiber rope and elevator, which is applied in the direction of elevators, yarn, transportation and packaging, etc., can solve the problems of increasing the weight of the car and the rope, requiring the use of additional ropes, and not adequately addressing the problems of synthetic materials. , to achieve the effect of reducing the overall space needed to operate the elevator and reducing the required torque of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Several embodiments of the claimed invention will now be described with reference to the Figures, wherein like numerals designate like elements.

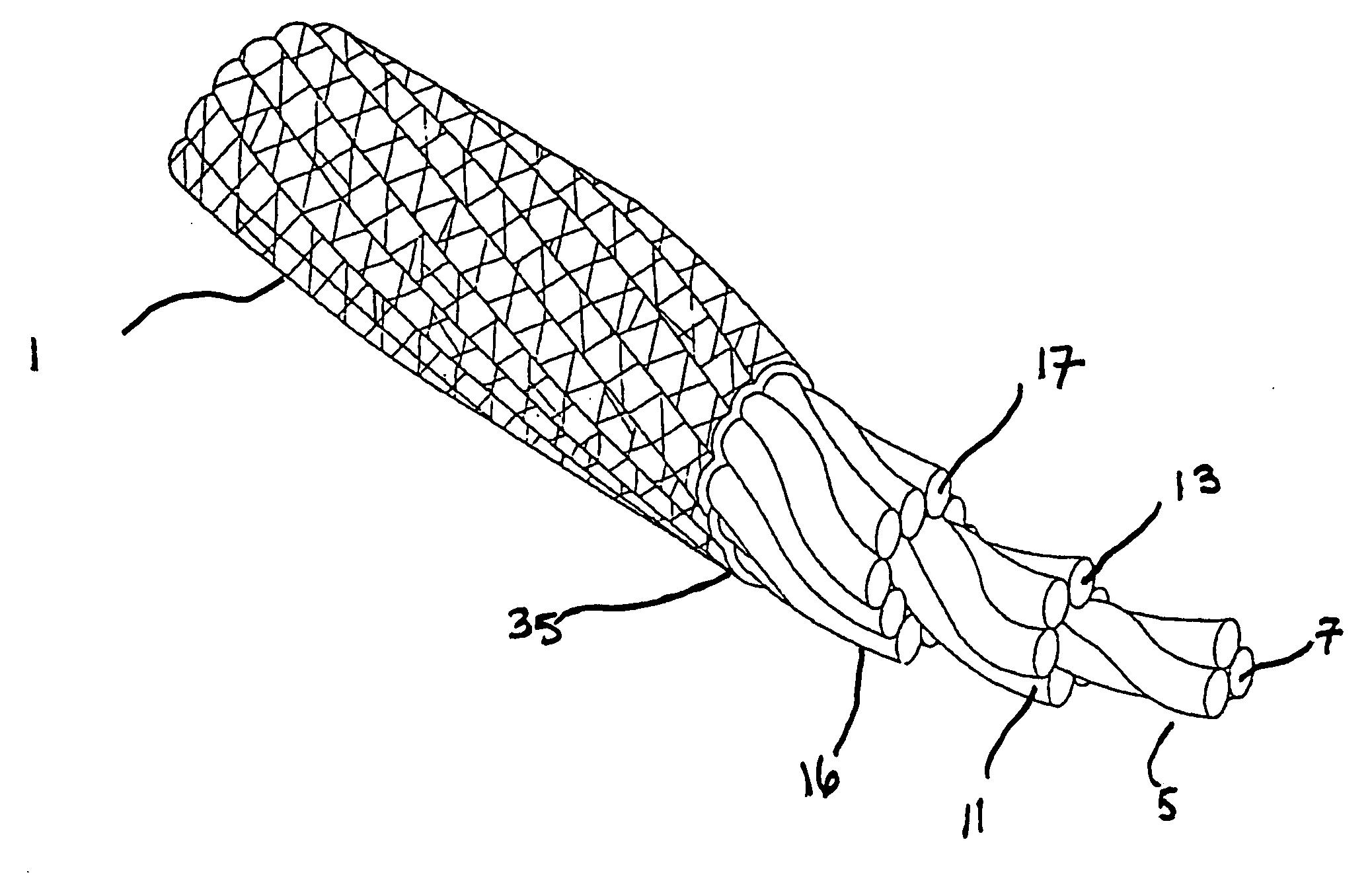

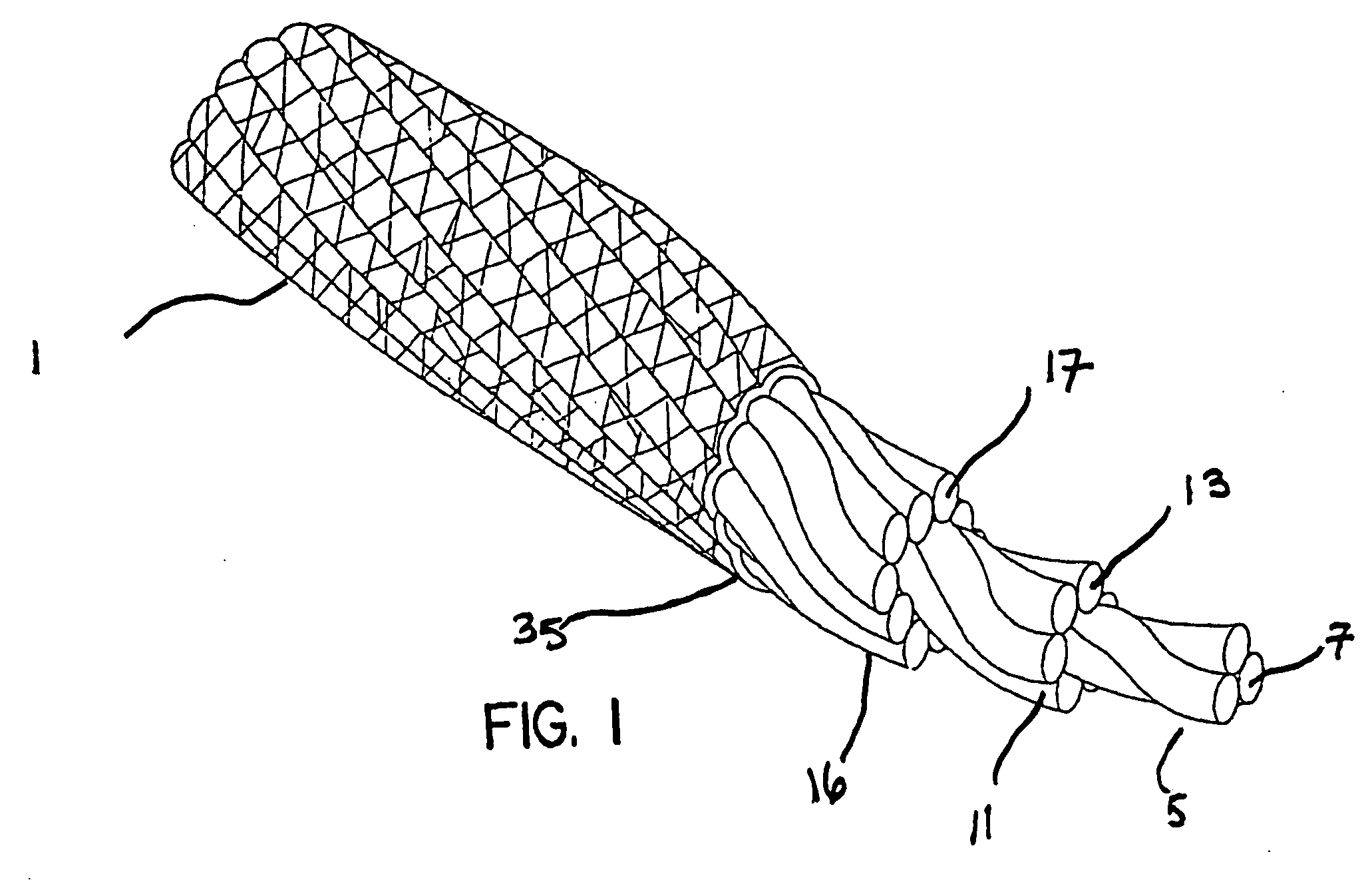

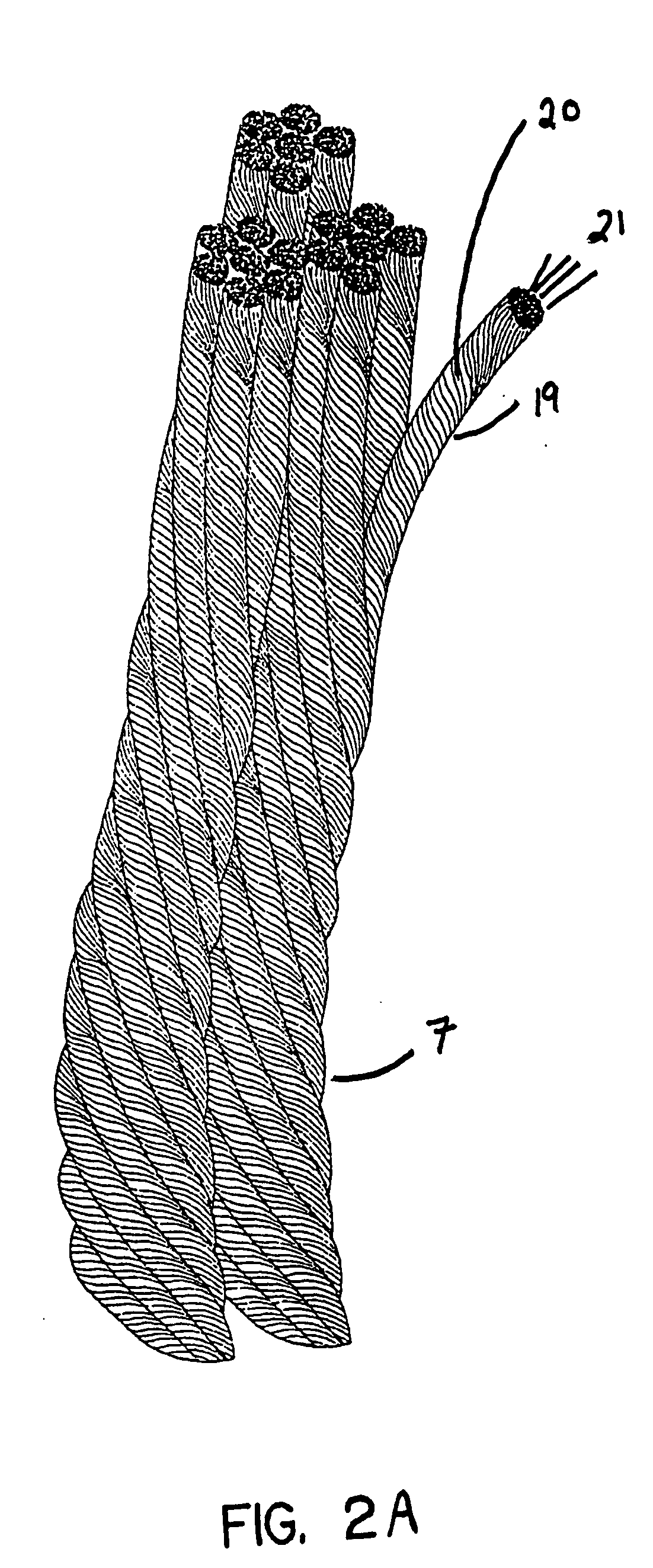

[0022] Referring to FIG. 1, showing one embodiment of the invention, the rope 1 includes an inner layer 5, a middle layer 11, an outer layer 16 and a jacket 35. The inner layer 5 contains three strands 7 wrapped around one another in a helical orientation. The middle layer 11 contains six strands 13 wrapped around the inner layer 5 in a helical orientation. The outer layer 16 contains twelve strands 17 wrapped around the middle layer in a helical orientation. The helical wrapping of each layer may be co-laid or vary in degree and direction from that of the preceding layer. In terms of degree, the helical angle of each layer may vary from 5 to 35°. Helix angle is determined using the following formula: tan HA=π xpLwhere:HA=helix anglep=pitch diameterL=lay length

[0023] In one embodiment, the lay of the helical angle for eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com