Enclosure for animals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

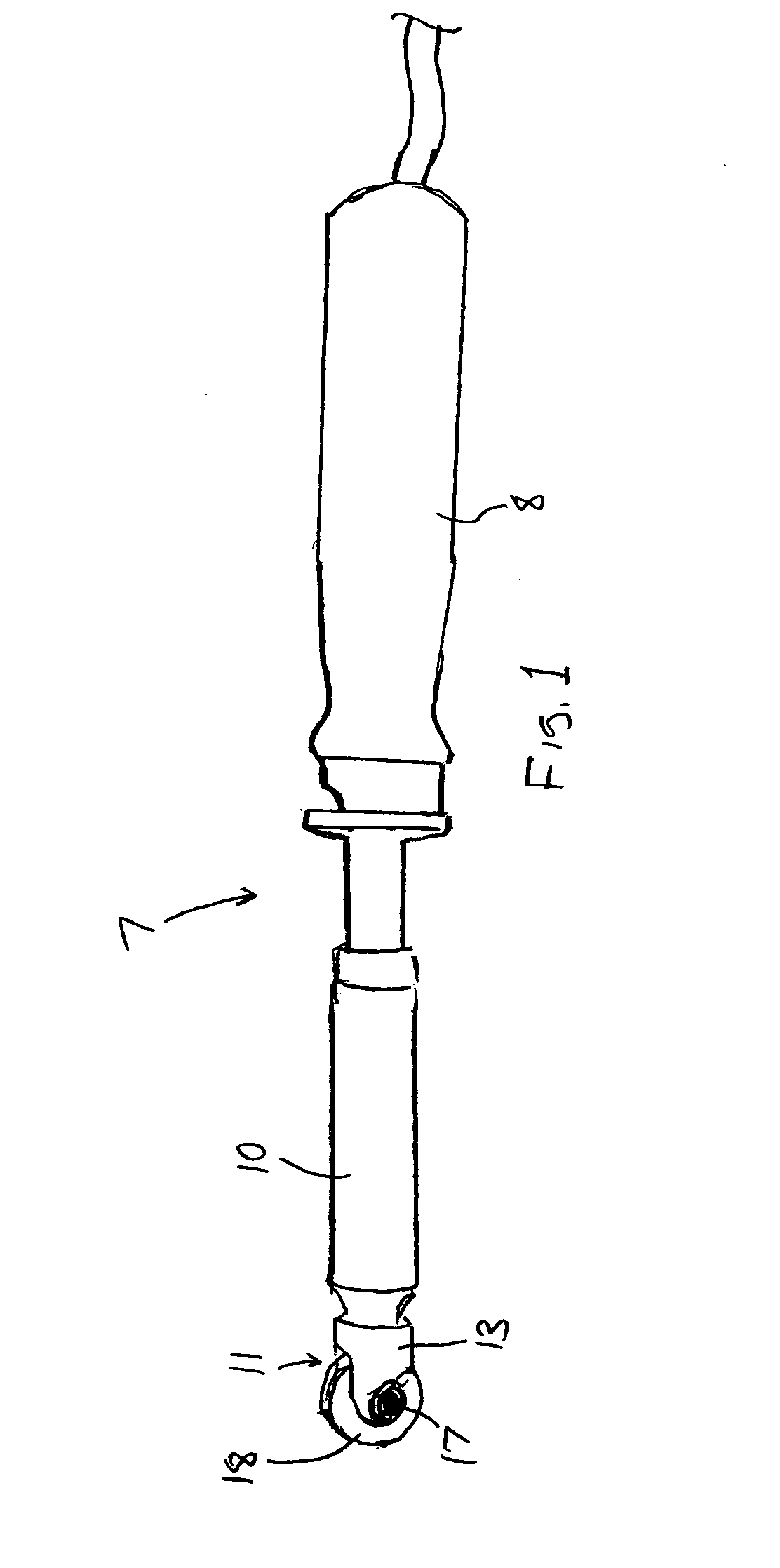

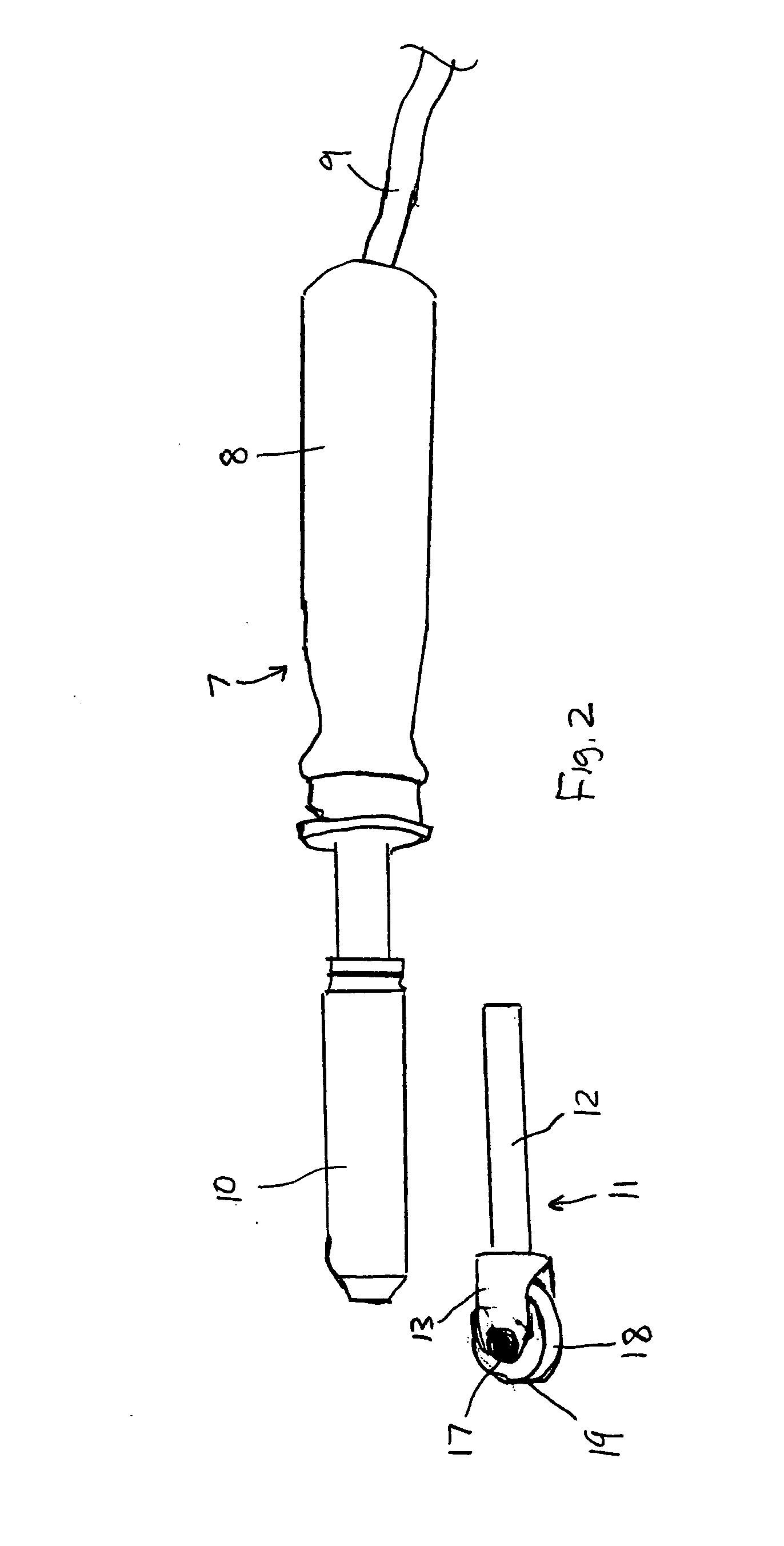

[0022] A method for the bonding of the upper film layer to the bottom film layer is required for the optimum performance of the film coating process. Due to the non-reactive properties of fluoropolymer films, this method must include the application of heat. Alternate methods of bonding have been tried with limited success, such as the use of adhesive “primers” or enhancers to create an acceptable attachment between the upper and lower film layers. This method still did not provide a permanent bond. Another approach incorporated the use of a directed “hot air” flow over the overlap of the film layers. This method was not successful because the heat could not be precisely directed or controlled and in many instances caused damage to an underlying fiberglass substrate.

[0023] The preferred method involves direct surface-to-surface heat transfer. A preliminary attempt to apply this method involved the use of a soldering iron pressed over the overlapping edges of the two film layers. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com