Constant temperature controller

a constant temperature controller and controller technology, applied in the direction of domestic cooling devices, lighting and heating devices, machines' operation modes, etc., can solve the problems of inability to precisely predict when the heat load that has been changed returns the heat load that has been changed may not always return from the external heat load apparatus, so as to quickly react to the fluctuation of the lead load, the operation status can be quickly stabilized, and the fluctuation of the temperature difference can be detected quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

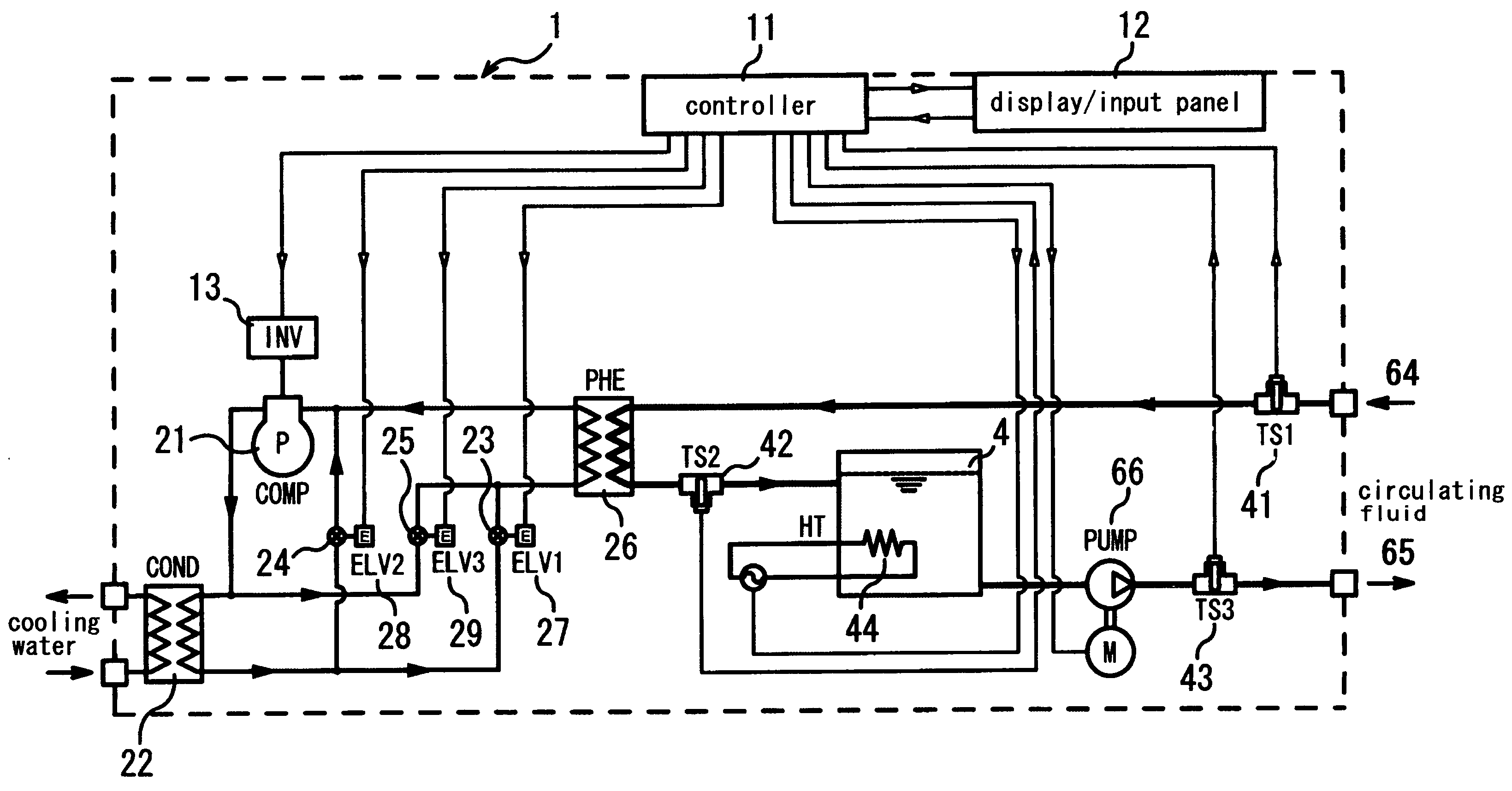

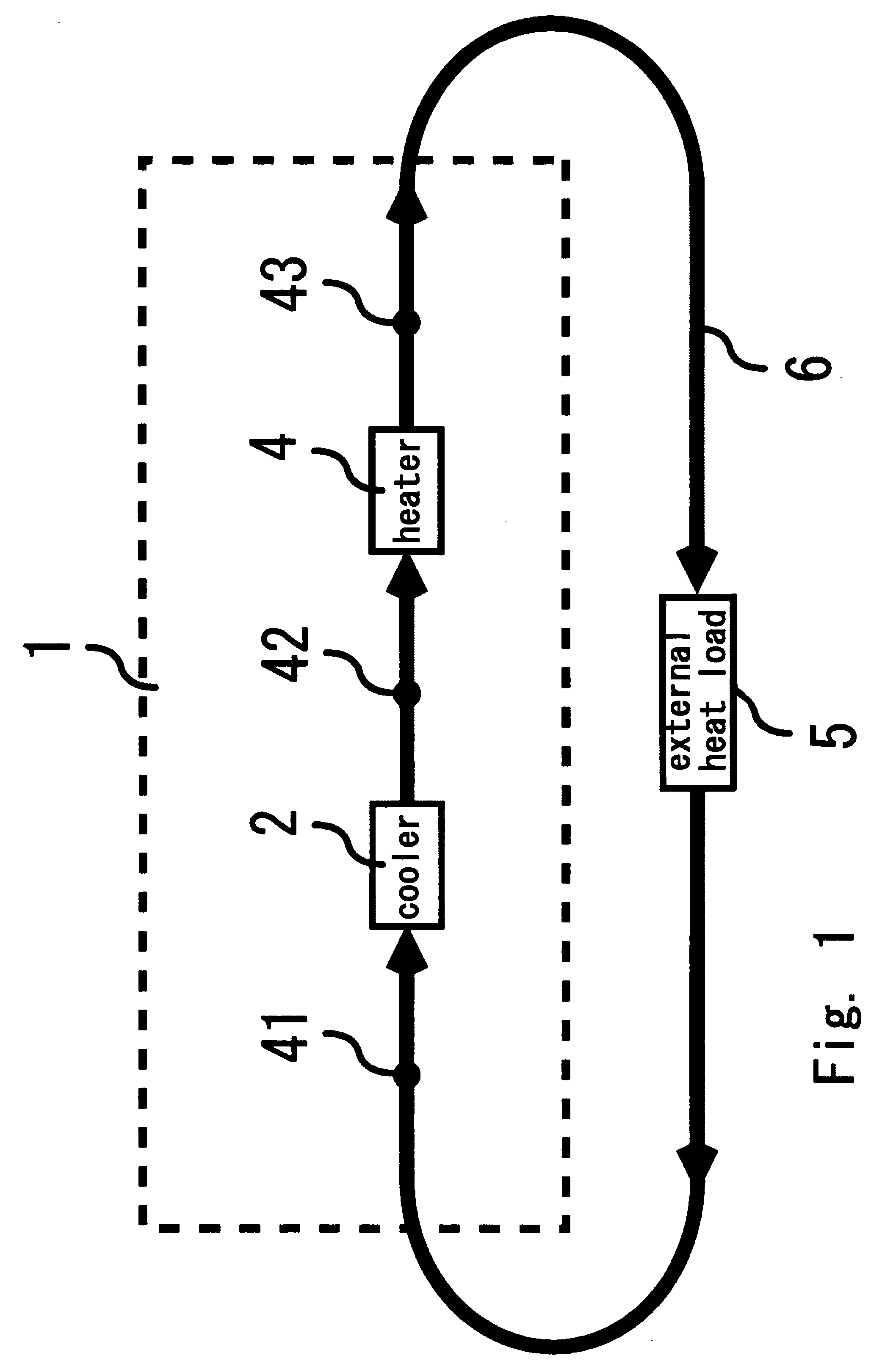

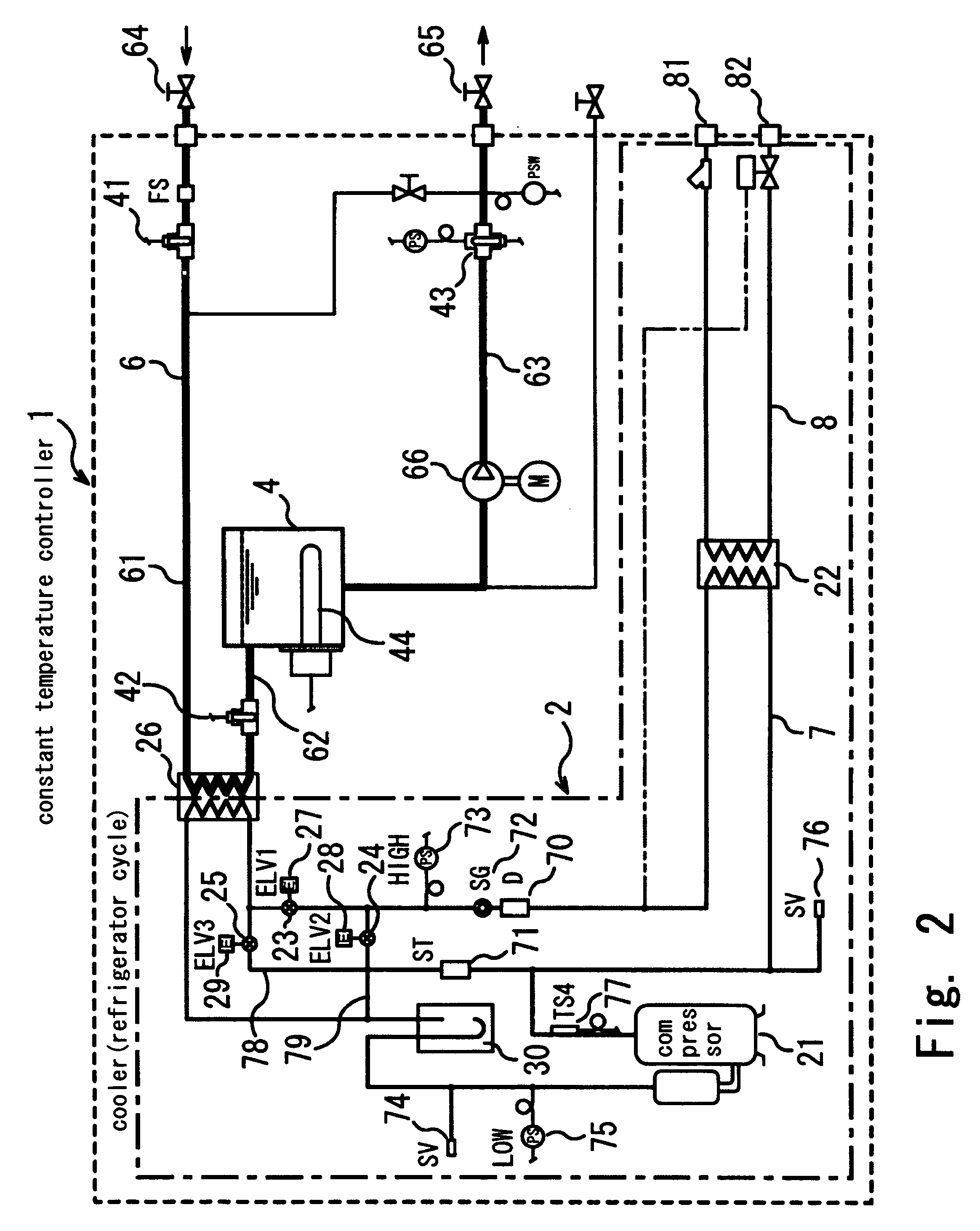

[0048]FIG. 1 is a block diagram schematically showing a configuration of a constant temperature controller, in which a portion enclosed by broken lines constitutes the constant temperature controller 1. The constant temperature controller 1 includes a cooler 2 and a heater 4. Numeral 5 designates an external heat load apparatus to be maintained at a constant temperature, such as an etching apparatus for semiconductor wafers, connected to the constant temperature controller via a pipeline 6 for a circulating fluid so as to constitute a closed loop.

[0049] In the pipeline 6, water is sealed in to serve as a heat medium. To the pipeline 6, temperature sensors for measuring the temperature of the heat medium are attached at some points. 41 designates a first temperature sensor that measures the circulating fluid temperature at the inlet port of the cooler, i.e. the temperature of the circulating fluid returning from the external heat load; 42 a second temperature sensor that measures th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com