Dual cassette load lock

a dual-cassette, load lock technology, applied in the direction of charging manipulation, lighting and heating apparatus, furnaces, etc., can solve the problem of significant increase in the time of semiconductor processing equipment, and achieve the effect of increasing the throughput of wafers through the workpiece processing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

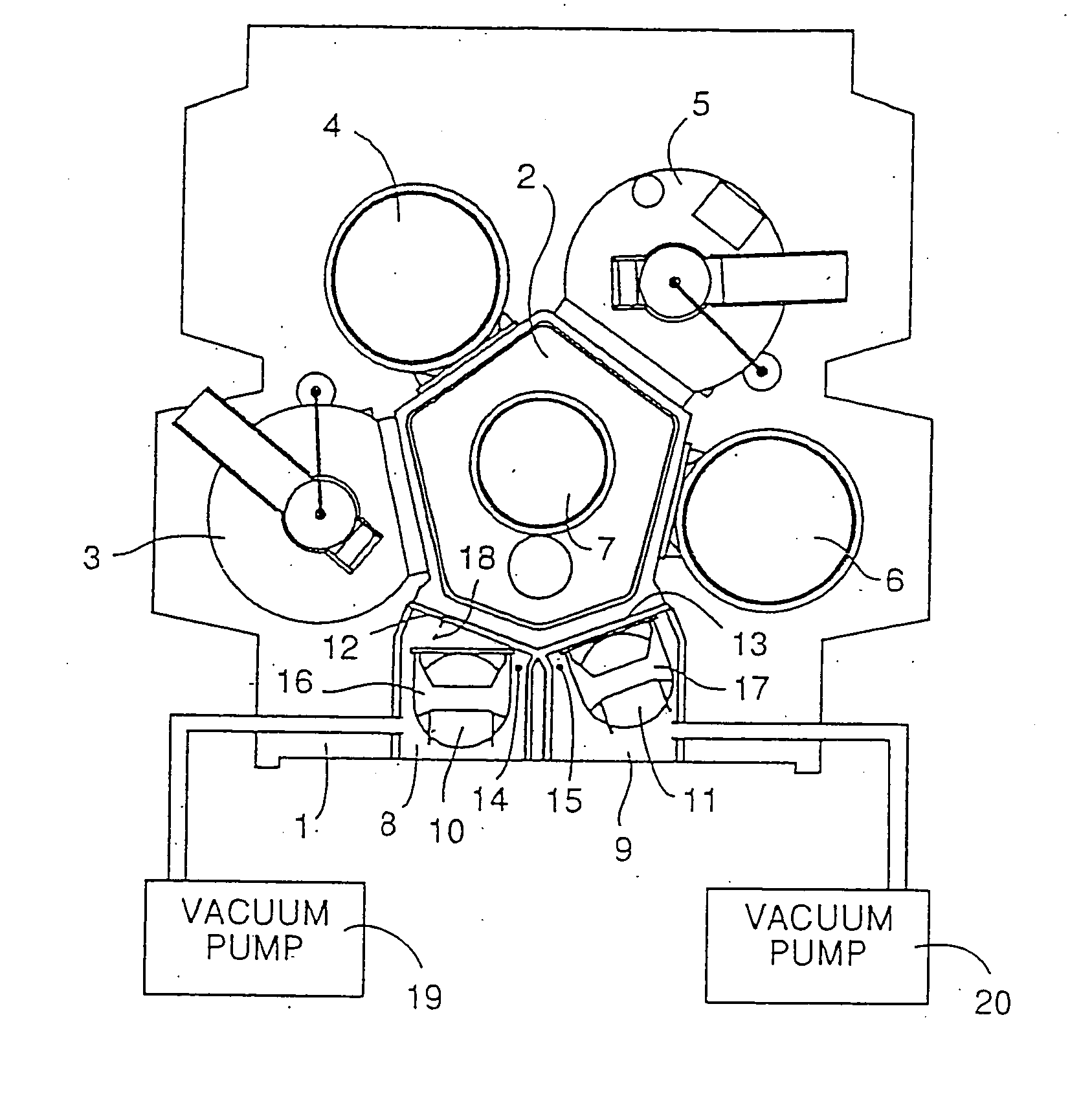

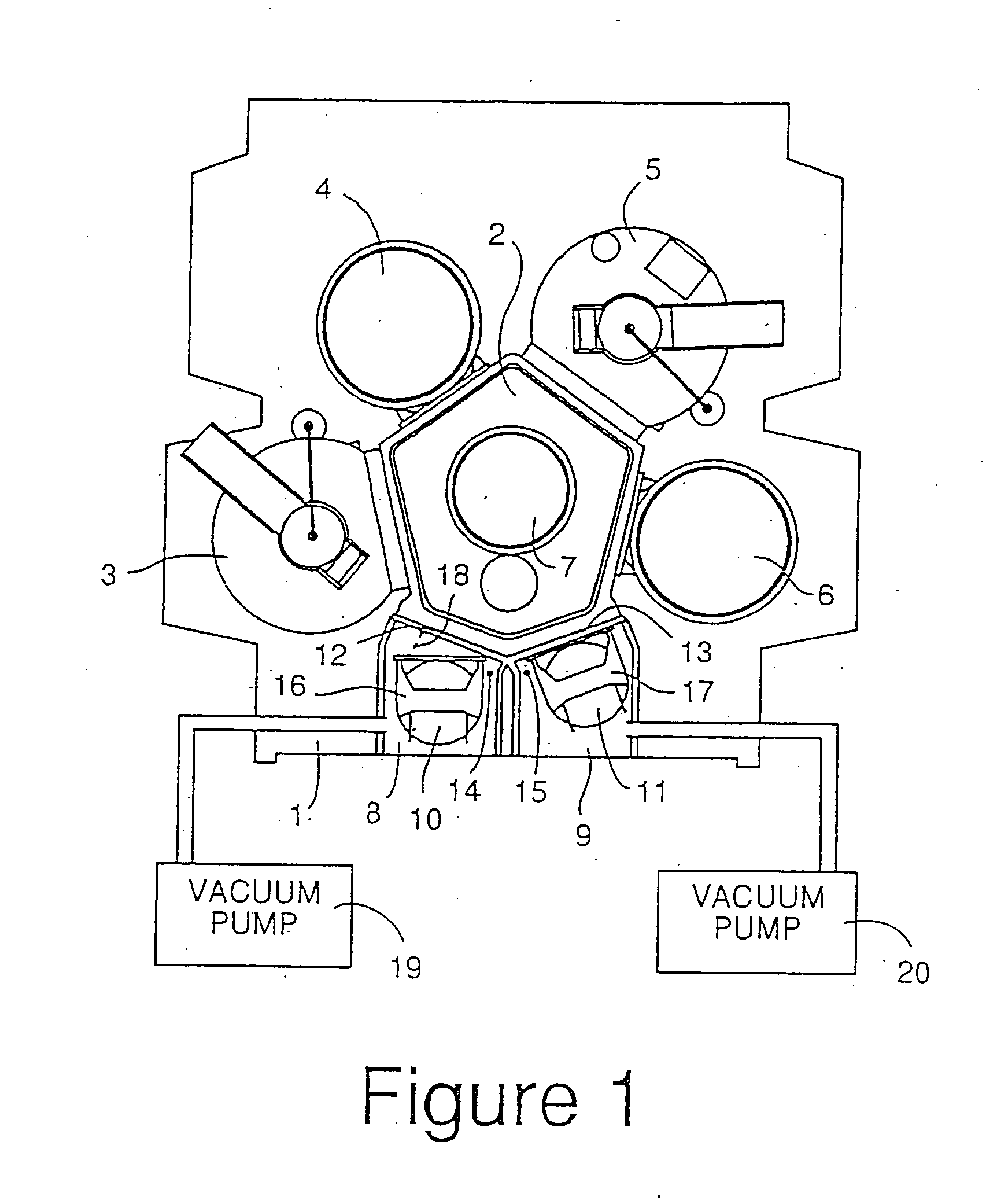

[0013] In FIG. 1, a top view of semiconductor processing equipment 1 is shown. Semiconductor processing equipment 1 may be used, for example, for etching wafers.

[0014] Semiconductor processing equipment1, includes, for example, a processing chamber 3, a processing chamber 4, a processing chamber 5 and a processing chamber 6. A central chamber 2 may be used to temporarily store wafers on robotic equipment 7 when wafers are being moved to or from various of the processing chambers.

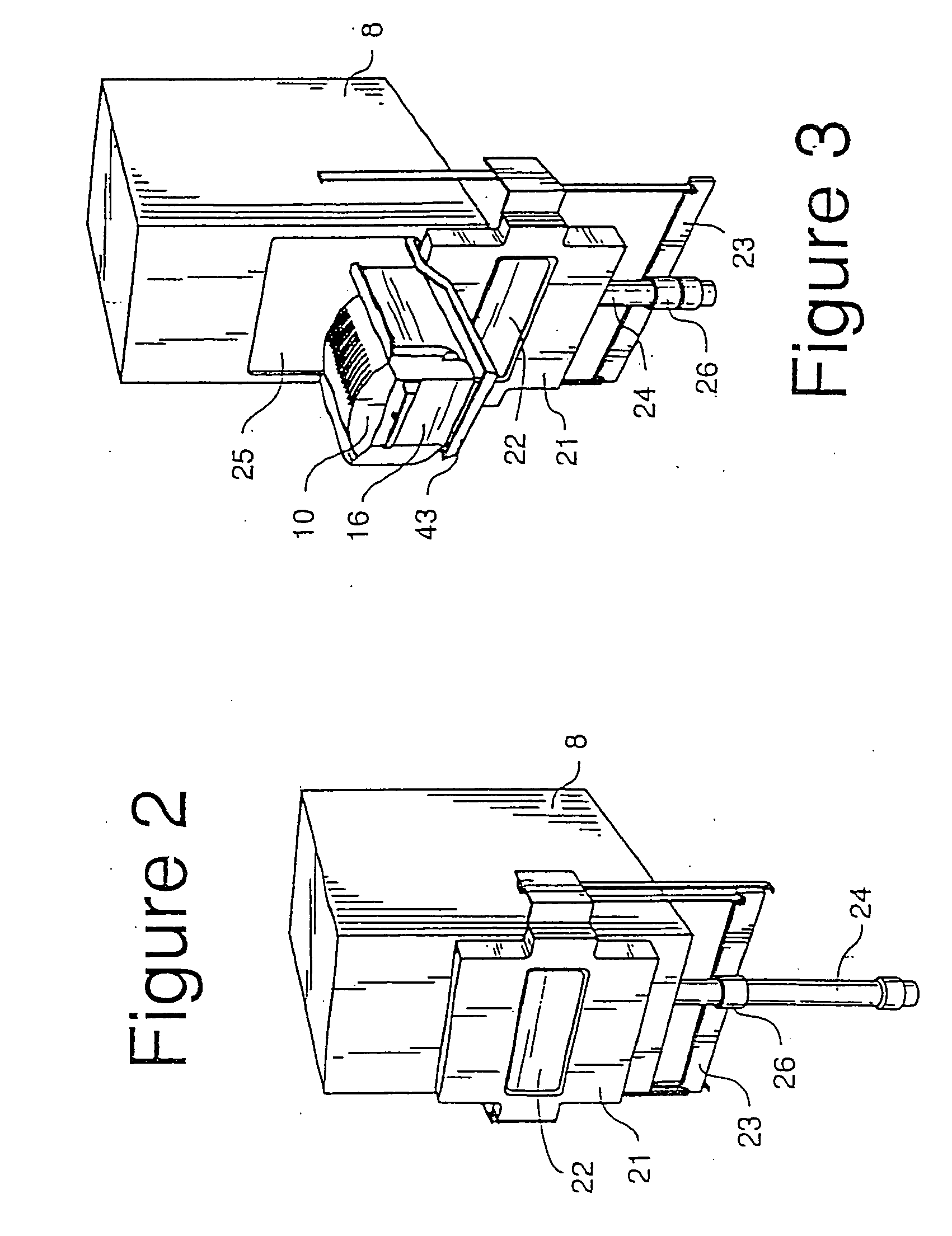

[0015] Semiconductor processing equipment 1 also includes dual cassette load locks. In chamber 8, a wafer cassette 16 holds wafers 10. In chamber 9, a wafer cassette 17 holds wafers 11. Wafer tray 17 pivots around a pivot point 15. When wafers 11 from tray 17 are accessed by semiconductor processing equipment 1 for processing, wafer tray 17 is flush against a gate 13, as shown, and easily accessed by robotic equipment 7 for transportation into central chamber 2. When wafer tray 17 is ready to be removed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com