Cleaning (de-poisining) PEMFC electrodes from strongly adsorbed species on the catalyst surface

a catalyst surface and electrode technology, applied in the field of fuel cells, can solve the problems of affecting the performance of pemfc, affecting the fc, and various impurities at levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

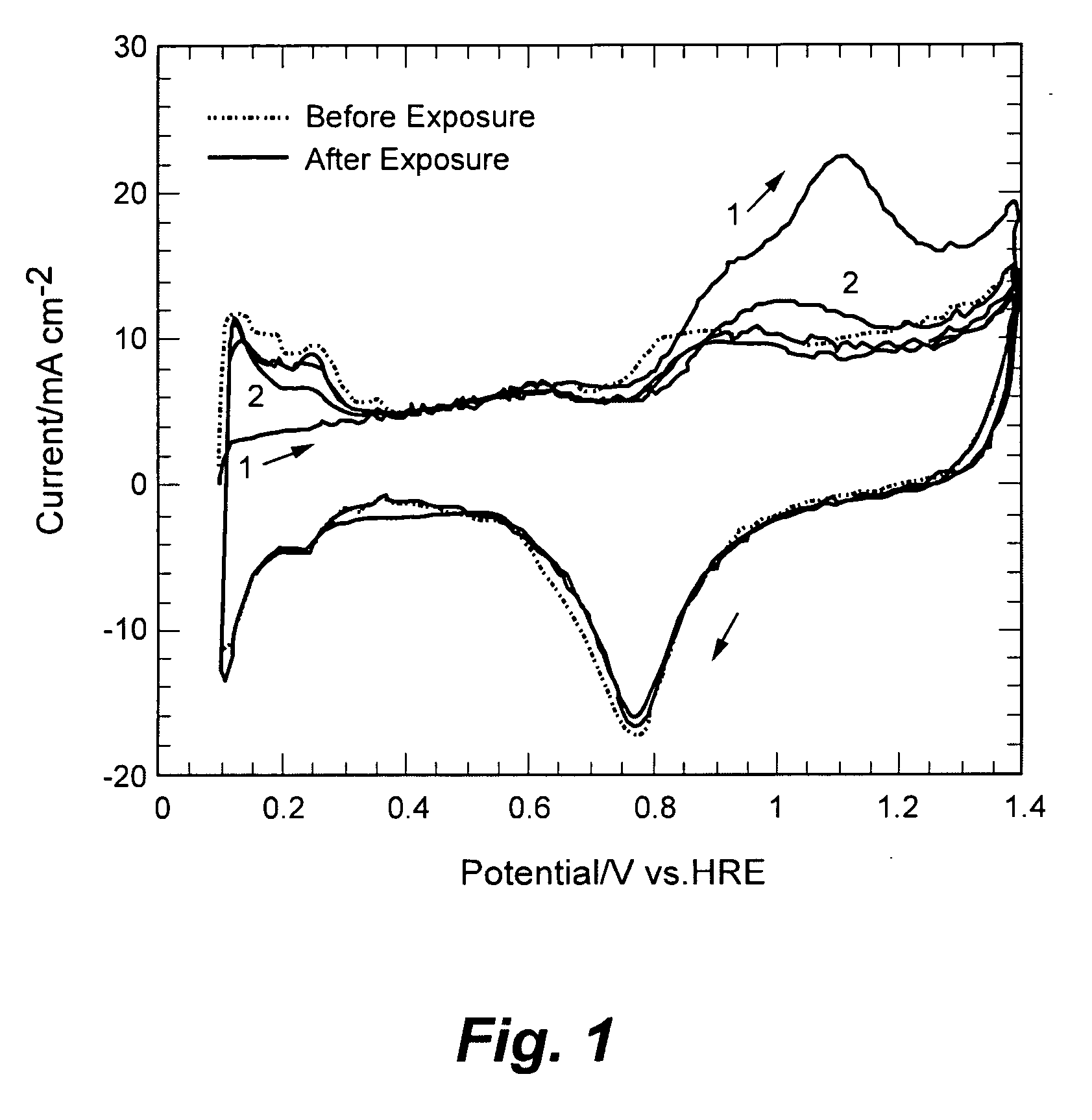

Cleaning a Fuel Cell Cathode Contaminated with SO2

Poisoning with SO2

[0024]FIG. 4 shows the cell current density as a function of time for a fuel cell experiment in which the cell operated at constant voltage (0.6 V). Initially the cell cathode ran on impurity-free air for 20 minutes and then operated with air contaminated with 10 ppm of SO2 for 20 minutes. The negative effect of the impurity on performance was observed as soon as the SO2 injection started and it is indicated by the sudden decrease in the current, which eventually dropped below 20% of the original value. Once the SO2 injection was interrupted, the cell ran on neat air again for about 24 minutes. A slow and small recovery was observed. Numerous SO2 poisoning tests indicate that the recovery does not improve even if the cell continued operating on clean air for several days.

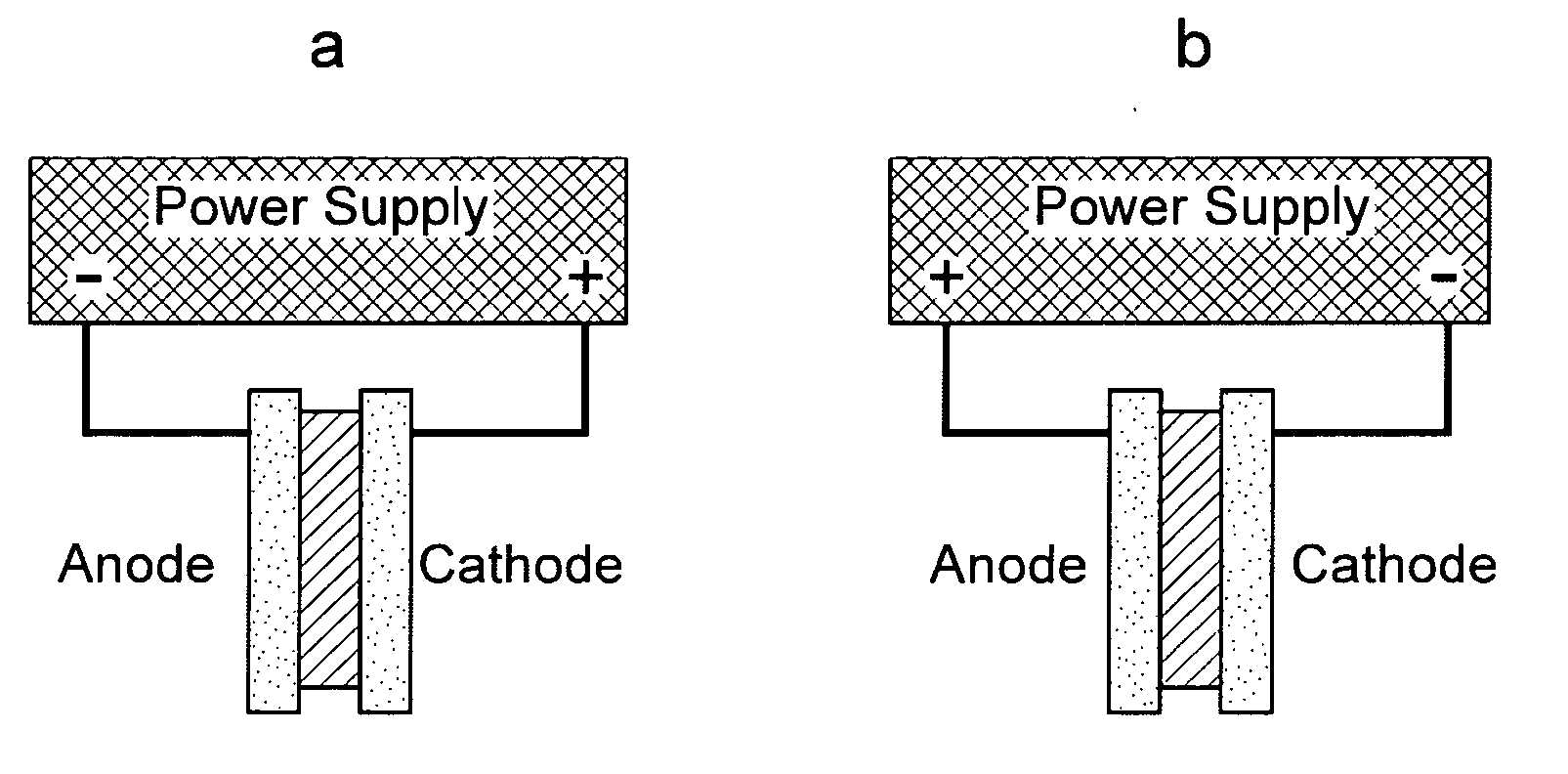

[0025] The fuel cell was momentarily turned off before the cleaning was started. Then, the positive terminal of the...

example 2

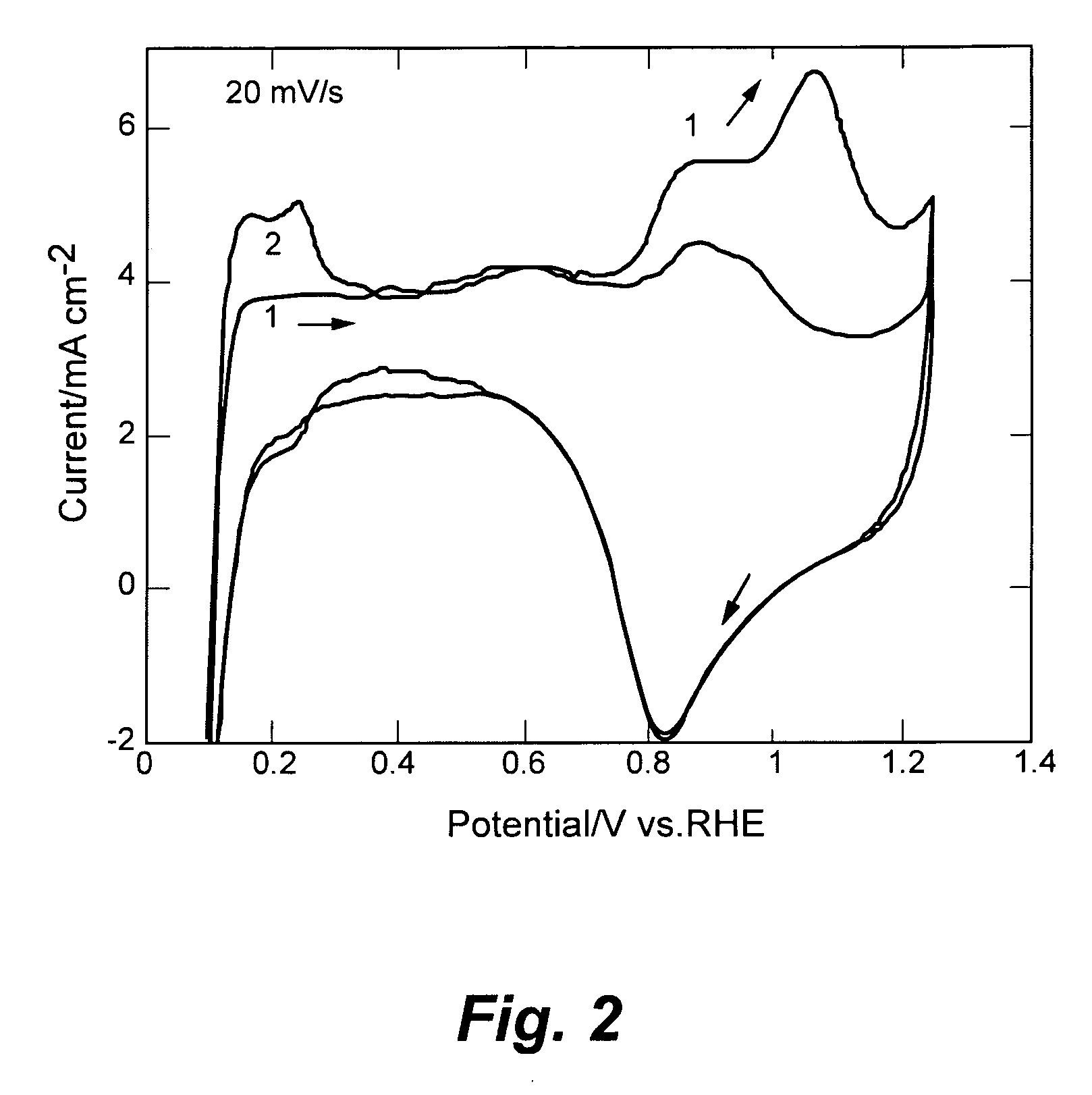

Cleaning a FC Anode Contaminated with H2S

Anode Poisoning with H2S and Cleaning Electrode with H2 Flow Interruption

[0026]FIG. 6 shows a similar experiment to example 1, but this time for an anode whose hydrogen fuel supply was contaminated with 2 ppm of H2S. Initially the cell ran on impurity-free hydrogen for 40 minutes, showing steady performance. Then it was exposed to H2S-contaminated hydrogen for 30 minutes. The cell current dropped considerably to 56% of its initial value. As expected, after stopping the injection of H2S the anode experienced insignificant recovery when the cell resumed operation on neat hydrogen again. Prior to applying the power pulse to the FC, the H2 gas flow was completely interrupted while the air flow was significantly reduced for about 10 minutes. This allowed the existing hydrogen at the anode to be consumed, leaving only the chemisorbed electroactive species on the Pt catalyst to be electro-oxidized by the external power pulse. Thus, prior consumpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fixed voltage | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com