Container for packaging perishable food items

a technology for packaging containers and food items, applied in the field of containers for packaging perishable food items, can solve the problems of wasting a great deal of space in current meat trays in retail display cases, and achieve the effect of minimizing the surface area of the container and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

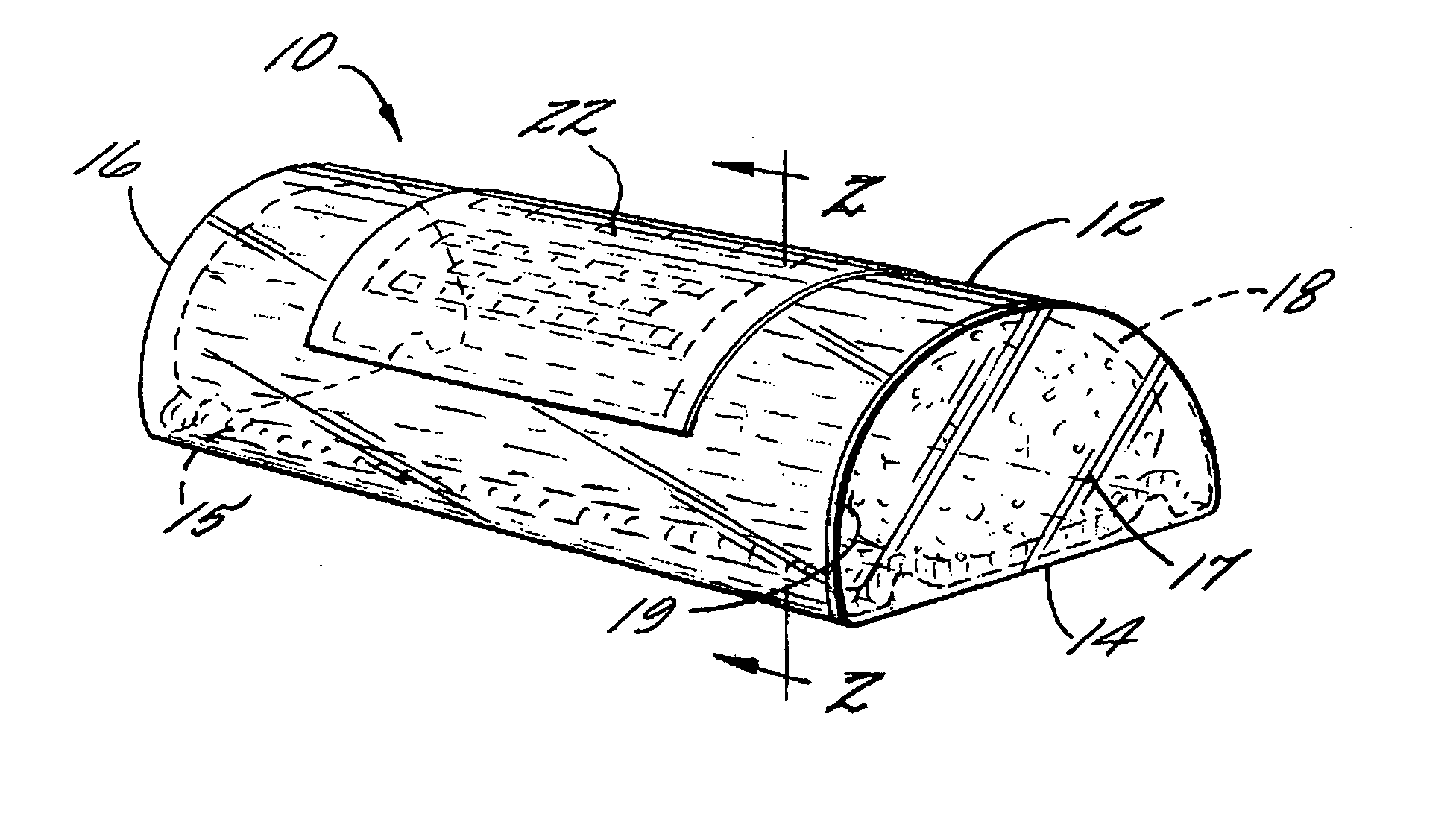

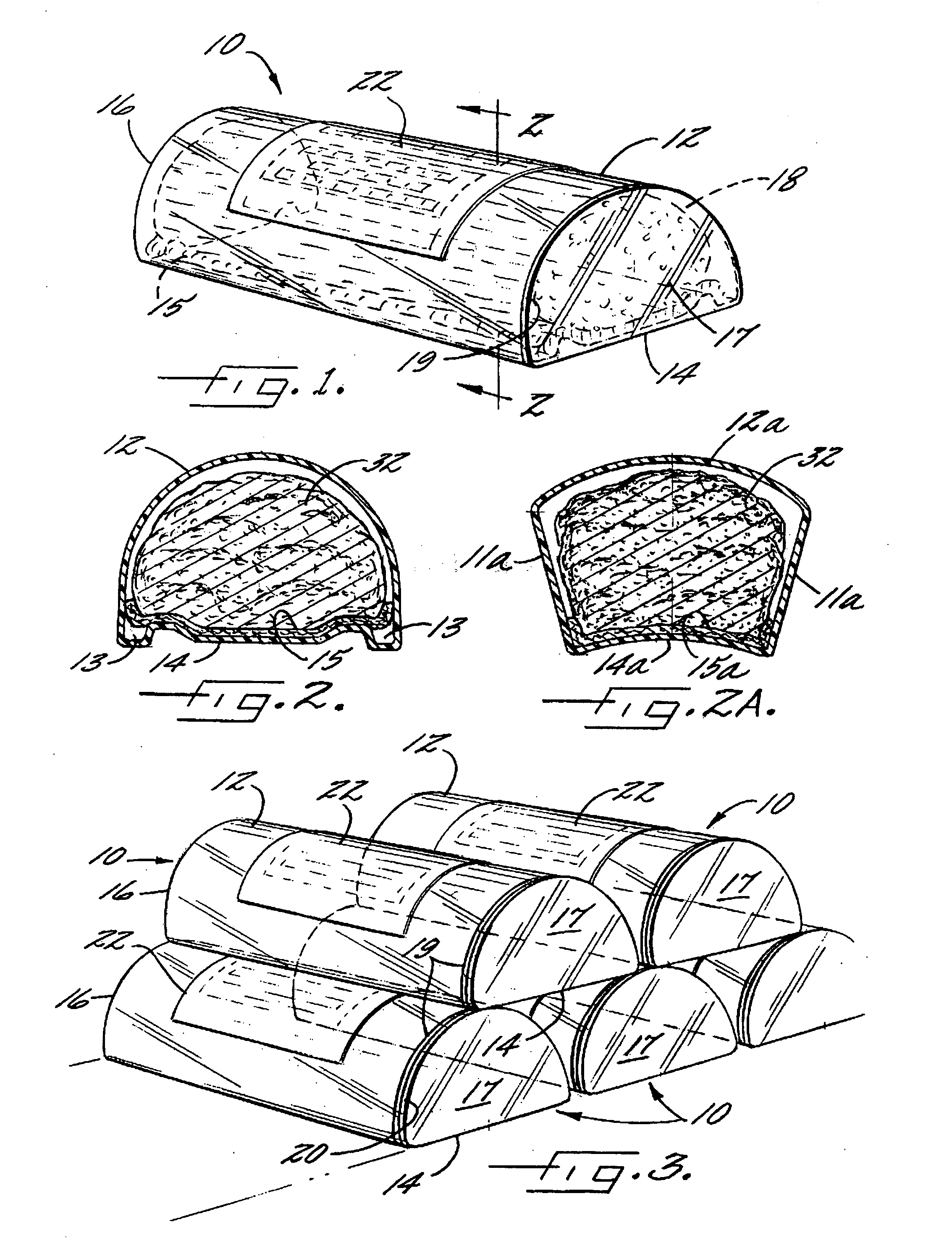

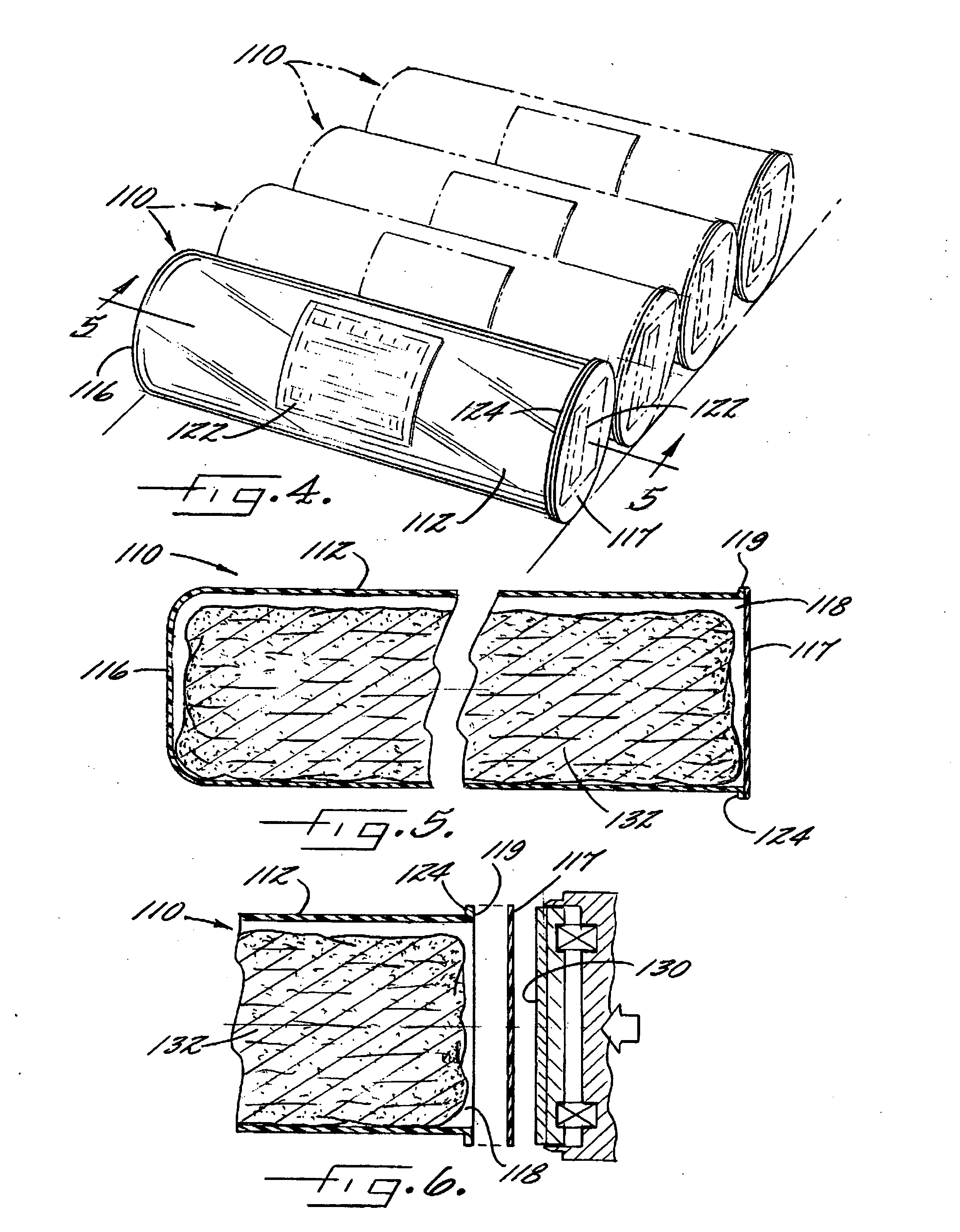

example 1

[0047] A blow molded container was made from PET. This container was trimmed to form a container of approximately rectangular cross section, with final dimensions of approximately 2.25×4.5×6 inches, the open end being approximately 2.25×4.5 inches. The aspect ratio of the container was thus 6 / 2.25=2.67. A section of this container was cut out, and measured per ASTM spec D 1003-97 using a Gardner Haze Guard Plus instrument, and the sample had a haze level of 3.1%. Product placed inside this sample was very visible.

[0048] Calculated permeation rates through the blow molded container described above were preformed to estimate the total permeation of oxygen into the container. Published permeation rates for oxygen through PET are 5 cc mil per 100 square inches of area. Thus, for a container having a thickness of 15 mils, the permeation rate of oxygen would then be 0.3 cc / 100 square inches, or approximately 4.65 cc per square meter. The net result would be an approximate permeation rate...

example 2

[0049] Containers as described in Example 1 are loaded with 1 pound of ground beef and stacked on a shelf in a standard 10 foot retail display case; the shelf holds 160 packages.

example 3

[0051] Fresh red meat in the form of ground beef was placed in a container as described in Example 1, and the open end was sealed with a PET lidding film. After the container was placed in a refrigerator maintained at 40° F., the inside of the container developed drops of condensation, which obscured the view of the meat product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com