Surface treating solution for fine processing of glass base plate having a plurality of components

a technology of surface treatment solution and glass base plate, which is applied in the direction of surface treatment composition, chemical apparatus and processes, etc., can solve the problems of local variation in etching rate and etching amount, mechanical thinning of mother glass plate, and interference with uniform etching/cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0069] The method of the invention will be described below more specifically by means of examples. However, the present invention is not limited to those examples.

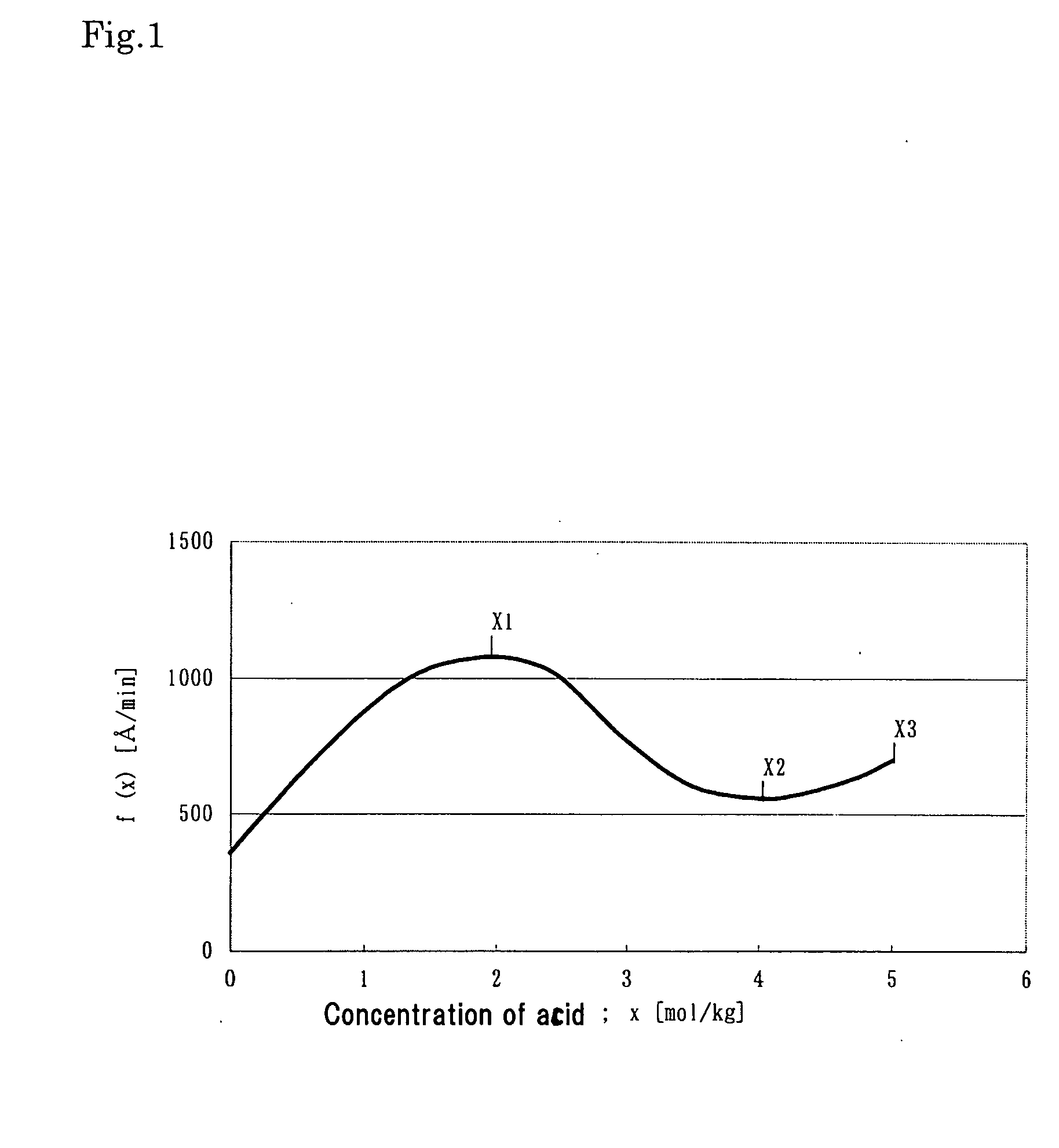

[0070] First, as a fundamental experiment, hydrochloric acid (HCl)-added BHF-based etching solutions were prepared with the concentration of HCl being varied. The compositions of the etching solutions and their features are summarized in Table 1 below.

TABLE 1Rate ofetching ofHFHydrochloricglass(mol / NH4Facidsubstratekg)(mol / kg)(mol / kg)(23° C.)(Å / min)Features0.510.2514400.52260Rate of etching ofheated oxide filmmaximum1.2538202.55000Rate of etching ofheated oxide filmminimum3.256120131305026700Rate of etching ofheated oxide filmmaximum39580412910Rate of etching ofheated oxide filmminimum515560330.542301.58090Rate of etching ofheated oxide filmmaximum2.7513640421060Rate of etching ofheated oxide filmminimum4.522780540.583101.514480Rate of etching ofheated oxide filmmaximum2.2518480425200

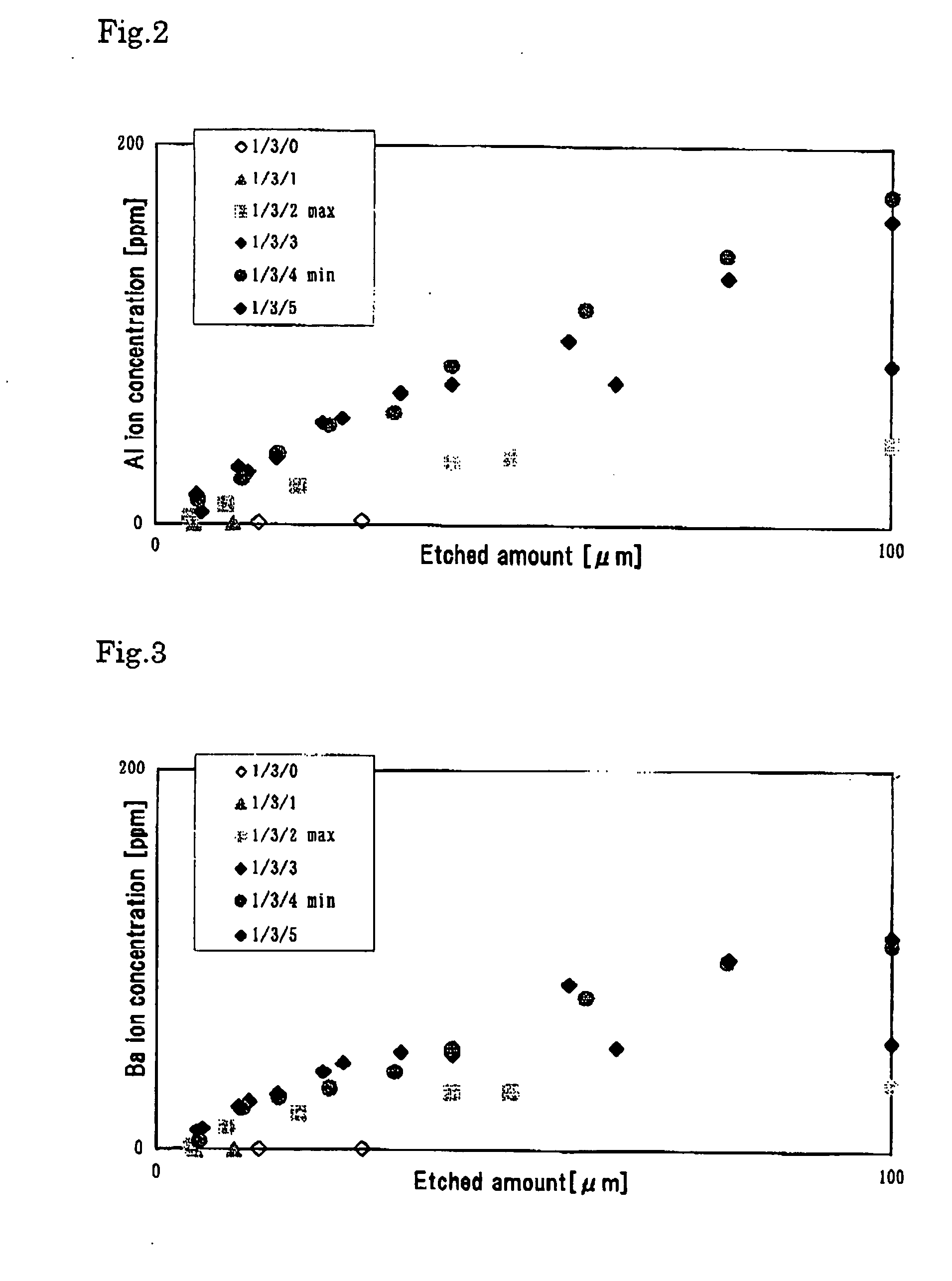

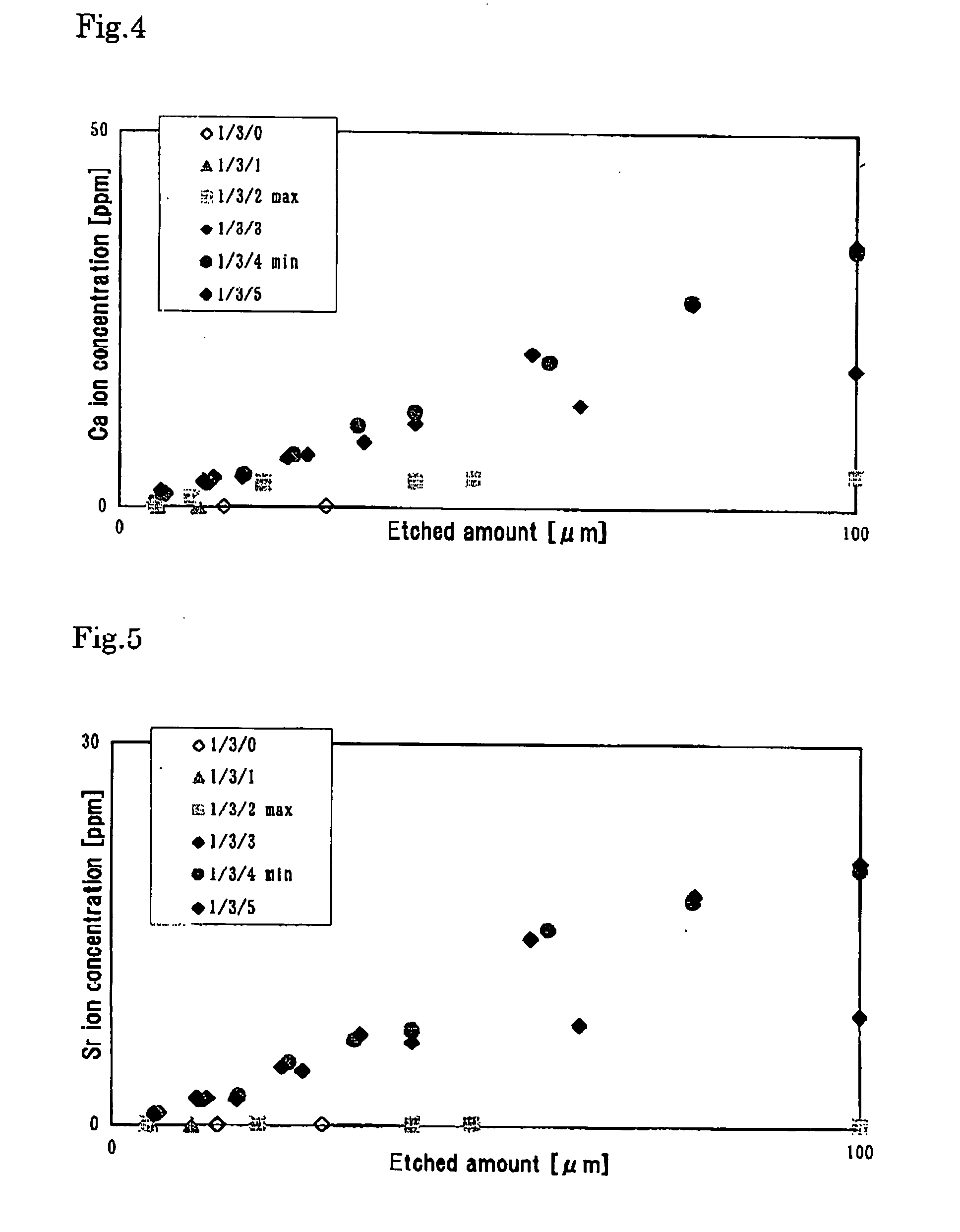

[0071] The glass substrate used in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| dissociation constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com