Exposure method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

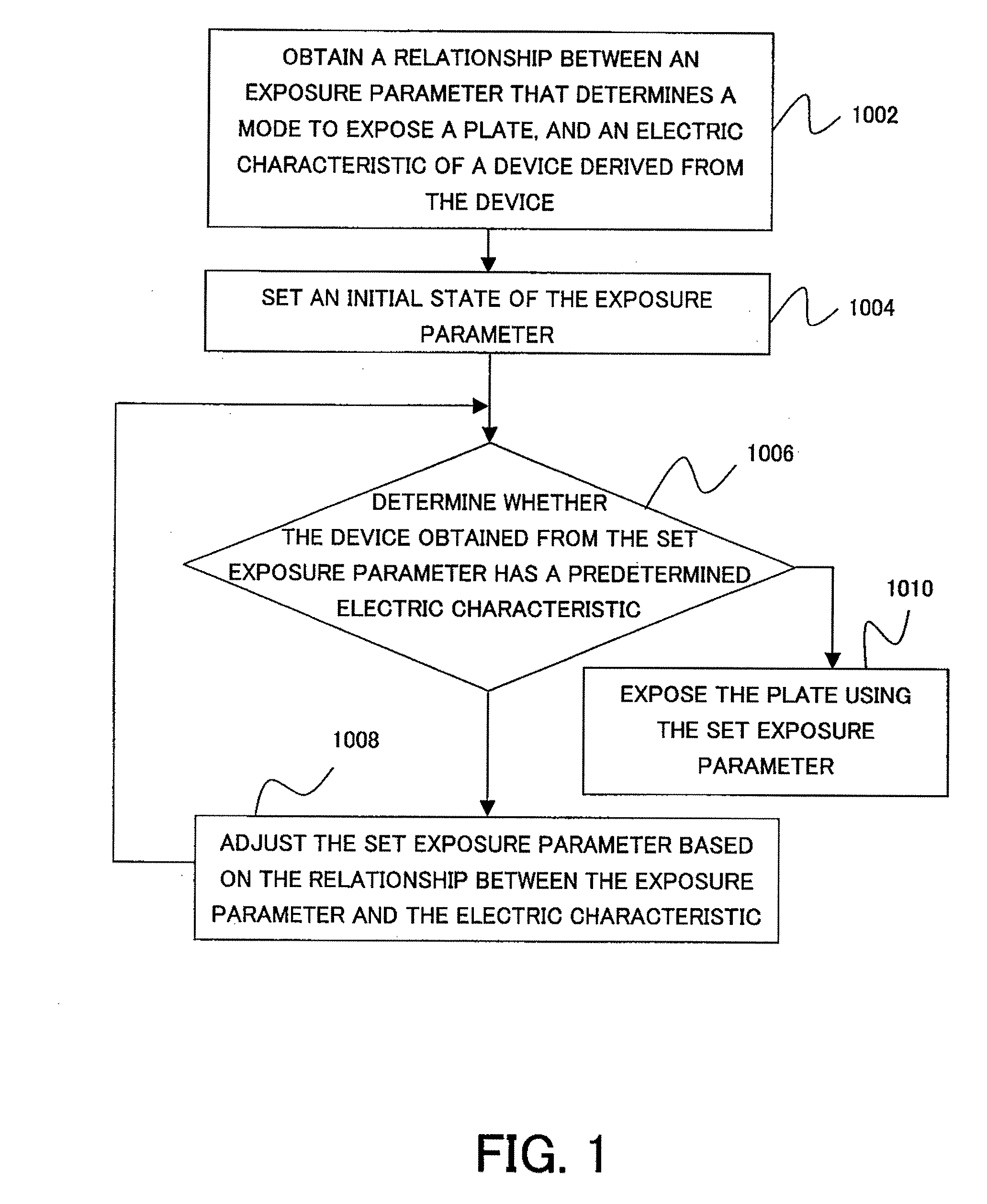

[0025] Referring now to the accompanying drawings, a description will be given of the preferred embodiments of the present invention. FIG. 1 is a flowchart of an optimization algorithm of this embodiment. FIG. 4 shows an exposure system 1 that executes the optimization algorithm shown in FIG. 1. The exposure system 1 includes, as shown in FIG. 4, a processing system 10 in a FAB (factory), input parts 20a-20c, an operating system 30, and exposure apparatuses 40a-40d.

[0026] The processing system 10 obtains reticle data and exposure condition from the input parts 20a to 20c, and selects an appropriate one of the exposure apparatuses 40a to 40d. The exposure apparatuses 40a to 40d have different characteristic data and specifications, such as a light source (ArF, KrF, EUV etc.), an exposure method (scanner, stepper, etc.), an illumination condition (polarization illumination, effective light source, etc.), and a projection optical system (dioptric, catadioptric, immersion system, etc.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com