Thermoplastic complex yarn with thermoforming function and thermoplastic fabric therewith

a technology of thermoforming function and thermoplastic fabric, which is applied in the direction of knitting, weaving, straight-bar knitting machines, etc., can solve the problems of fabric without plasticity and external surface of the bottom of the fabric, and achieve the effect of improving the structure and support strength of the thermoplastic complex yarn, increasing the application field, and improving the convenience of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structural features and the effects to be achieved may further be understood and appreciated by reference to the presently preferred embodiments together with the detailed description.

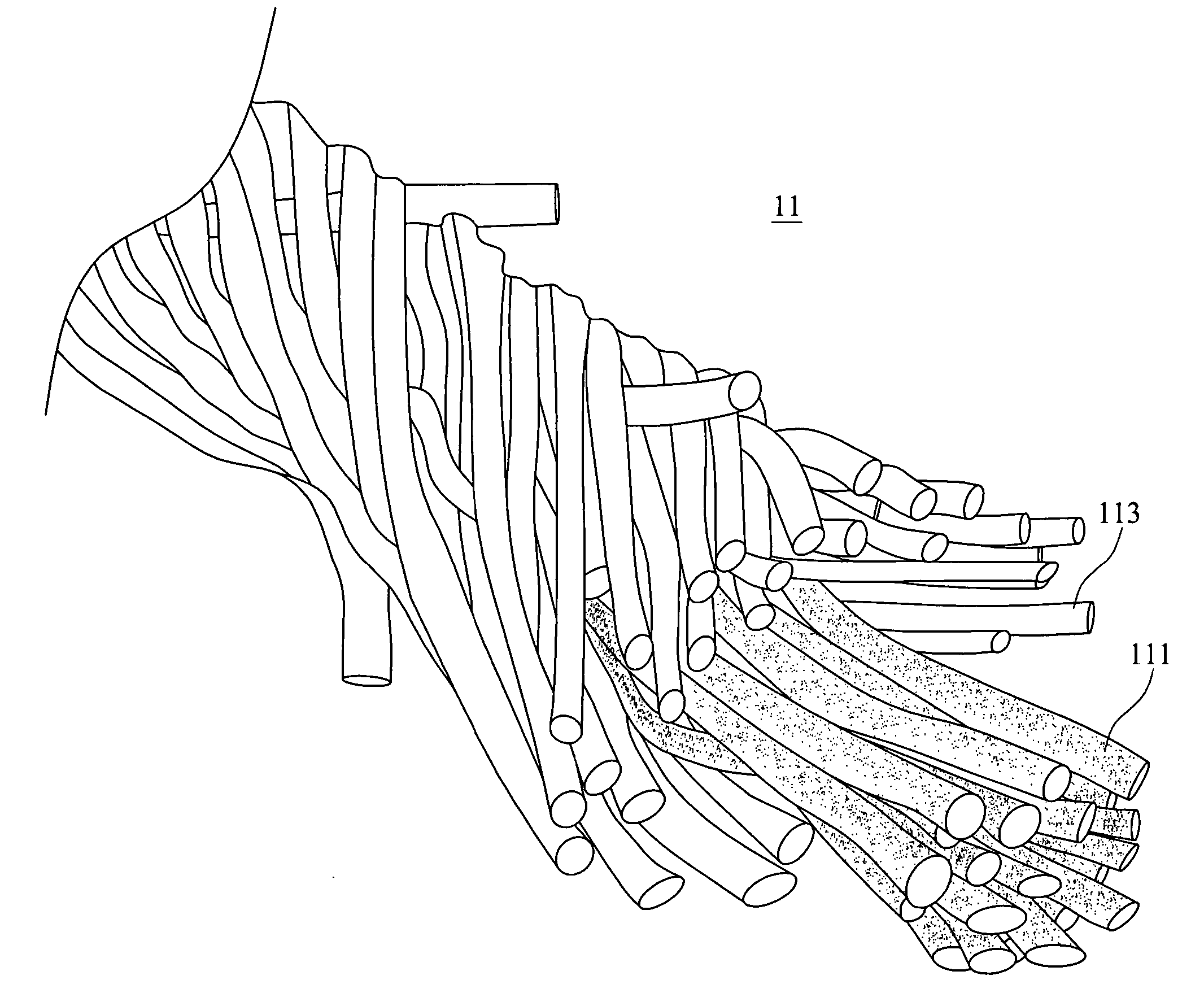

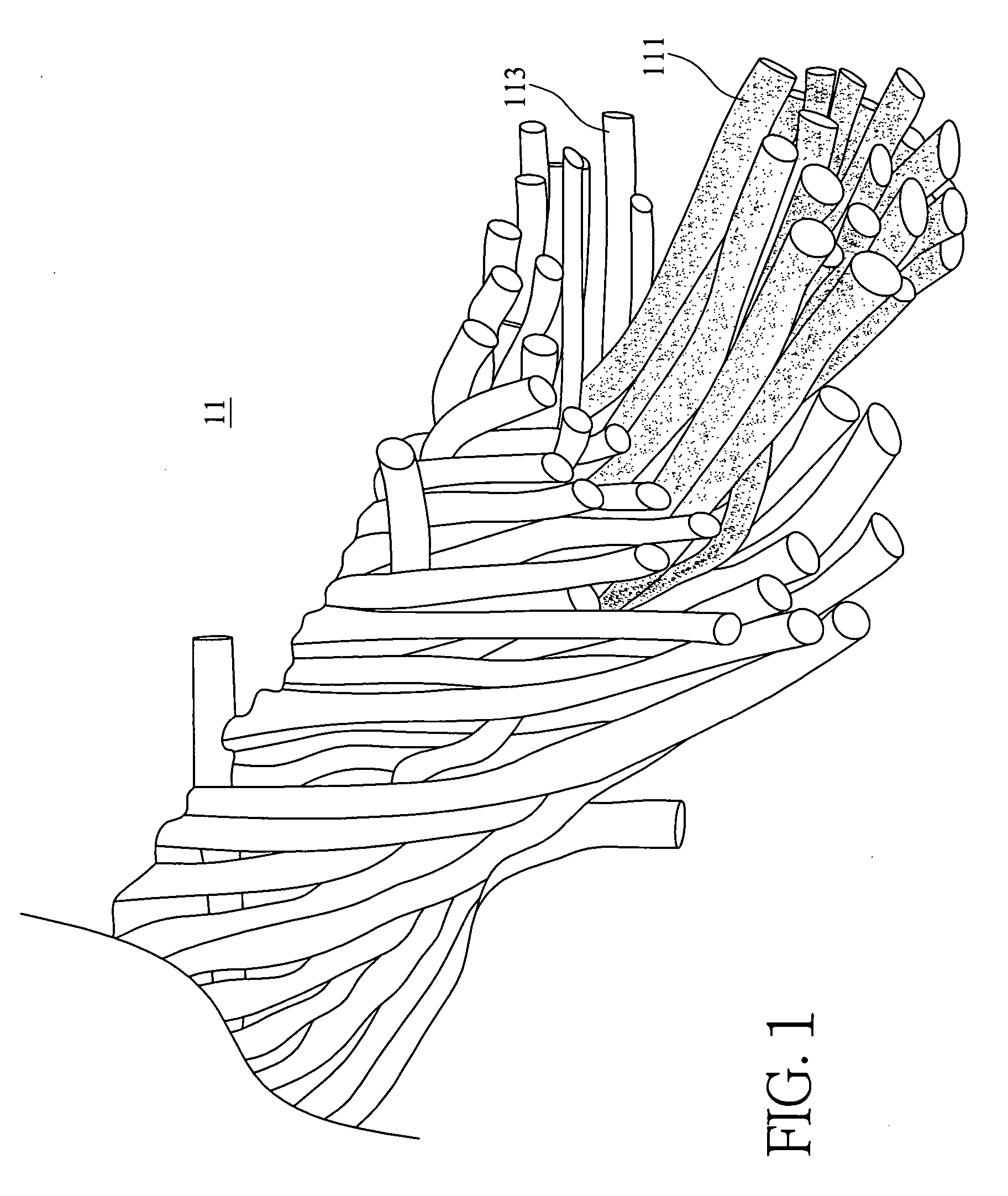

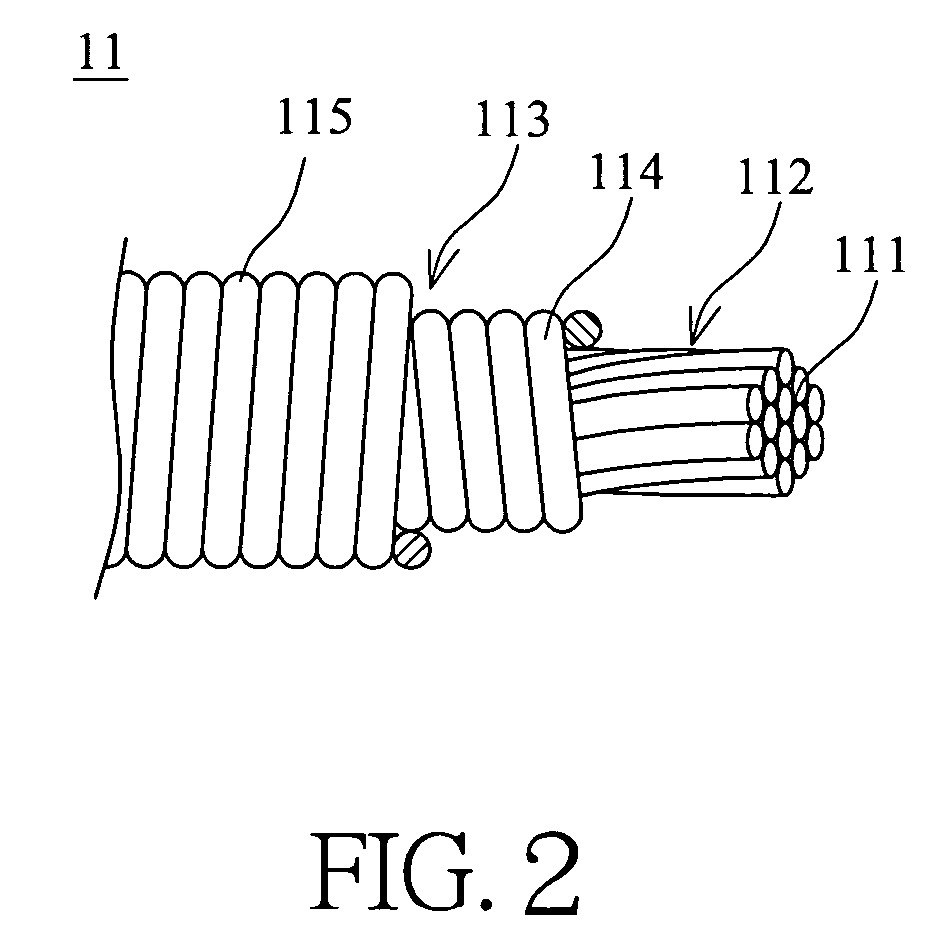

[0022] Referring to FIG. 1, is a three-dimensional view of a preferred embodiment of the present invention thermoplastic complex yarn with thermoforming function. A low temperature hot melt fiber 113 winds around the peripheral of a high strength fiber 111 to form a thermoplastic complex yarn 11 with thermoforming function. When the thermoplastic complex yarn 11 is processed by a hot-pressing procedure, such can be transformed easily to a desired figure, according to the low temperature hot melt fiber 113 with thermoforming feather. Further, the high strength fiber 111 will be formed as the desired figure (as reference symbol 101 shown on FIG. 6B) following the low temperature hot melt fiber 113, which further efficiently improves the support and structure strength of the thermoplastic comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com