Cellularcrete wall system

a cell concrete and wall technology, applied in the field of aerated concrete, can solve the problems of insufficient field labor, increased building material cost, and inability to meet the requirements of construction, and achieve the effect of saving labor and material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

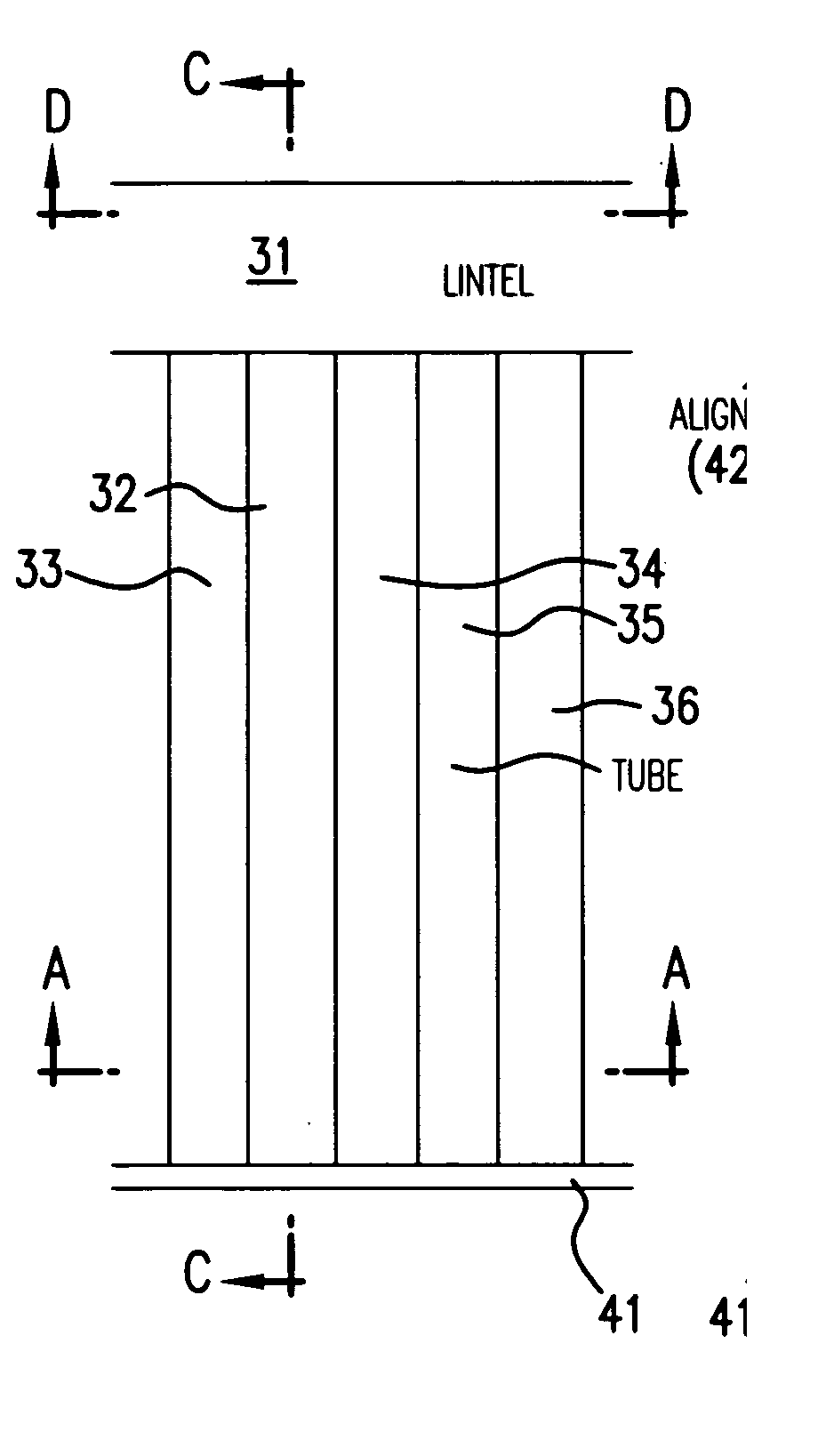

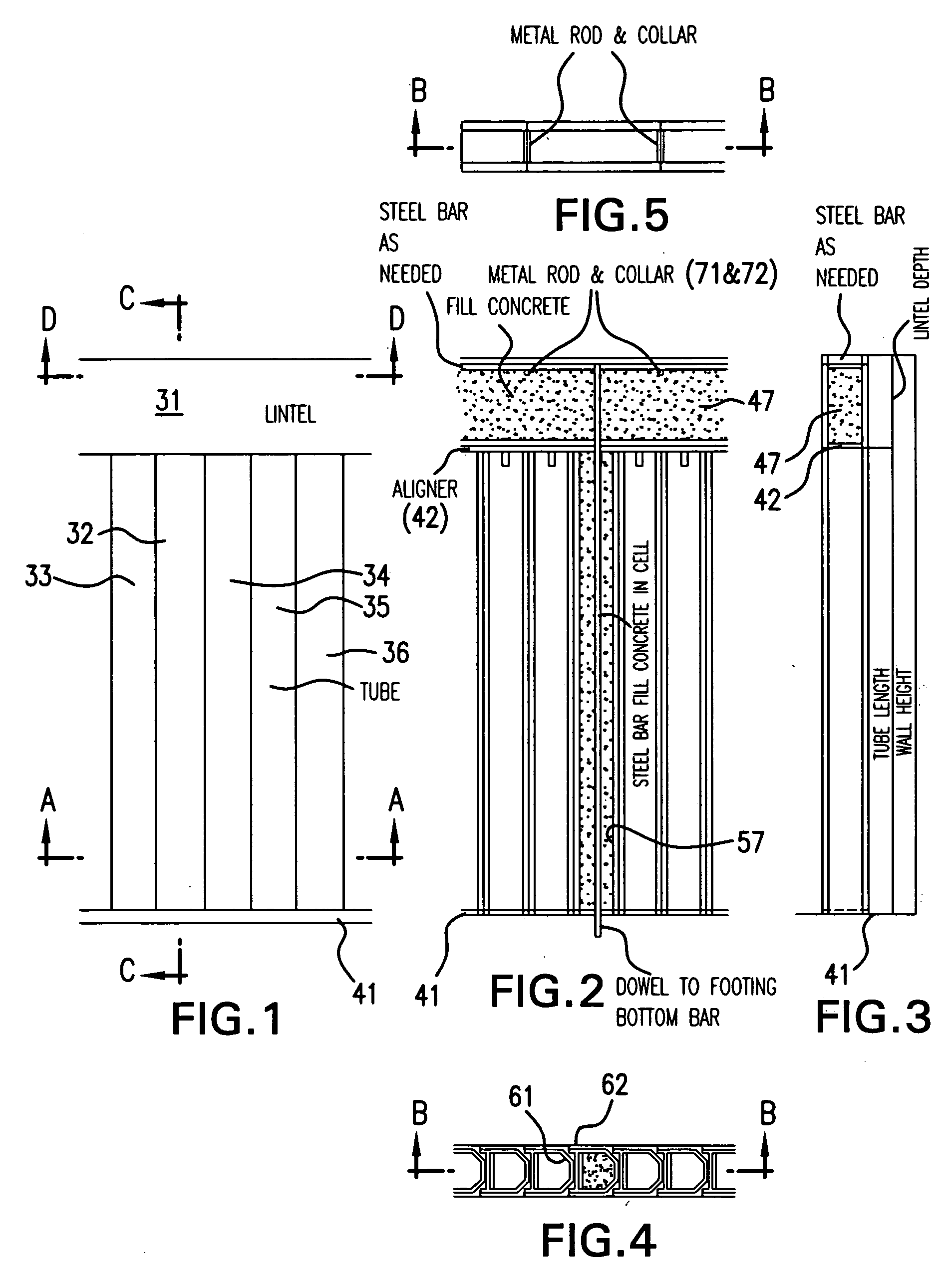

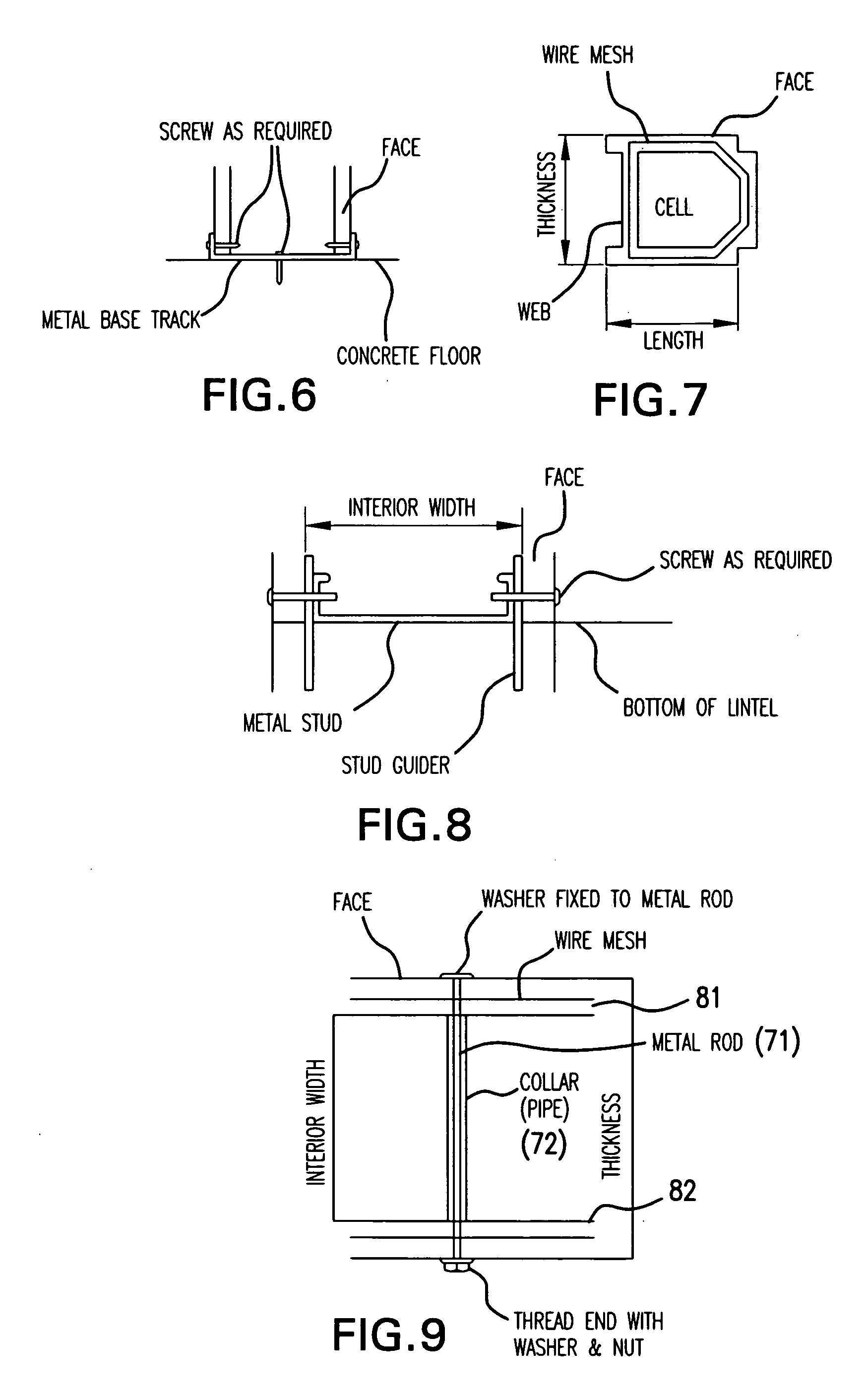

[0025] Reference now is made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals indicate like elements throughout the several views.

[0026] The technology for manufacturing AAC block has been well defined and adopted by the construction industry. The high strength concrete also has been widely used in bridges and high rise building structures. The low density AAC generally is not strong enough for use as load bearing walls.

[0027] This invention provides biaxial fiber mesh inside the AAC structural component to increase the mechanical strengths of the structure, as studied in THE ELASTIC STABILITY OF FIBERS IN COMPOSITE MATERIALS, January 1969, by Wen Y Chung, et al., for compressive load-bearing applications. This invention also uses high strength concrete to increase the strength of the AAC structural component. Because of the increased strengths, a wall is able to be buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com