Microarray having a base cleavable succinate linker

a succinate linker and microarray technology, applied in the field of microarrays, can solve the problems of low yield and reaction conditions that require a relatively long period of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

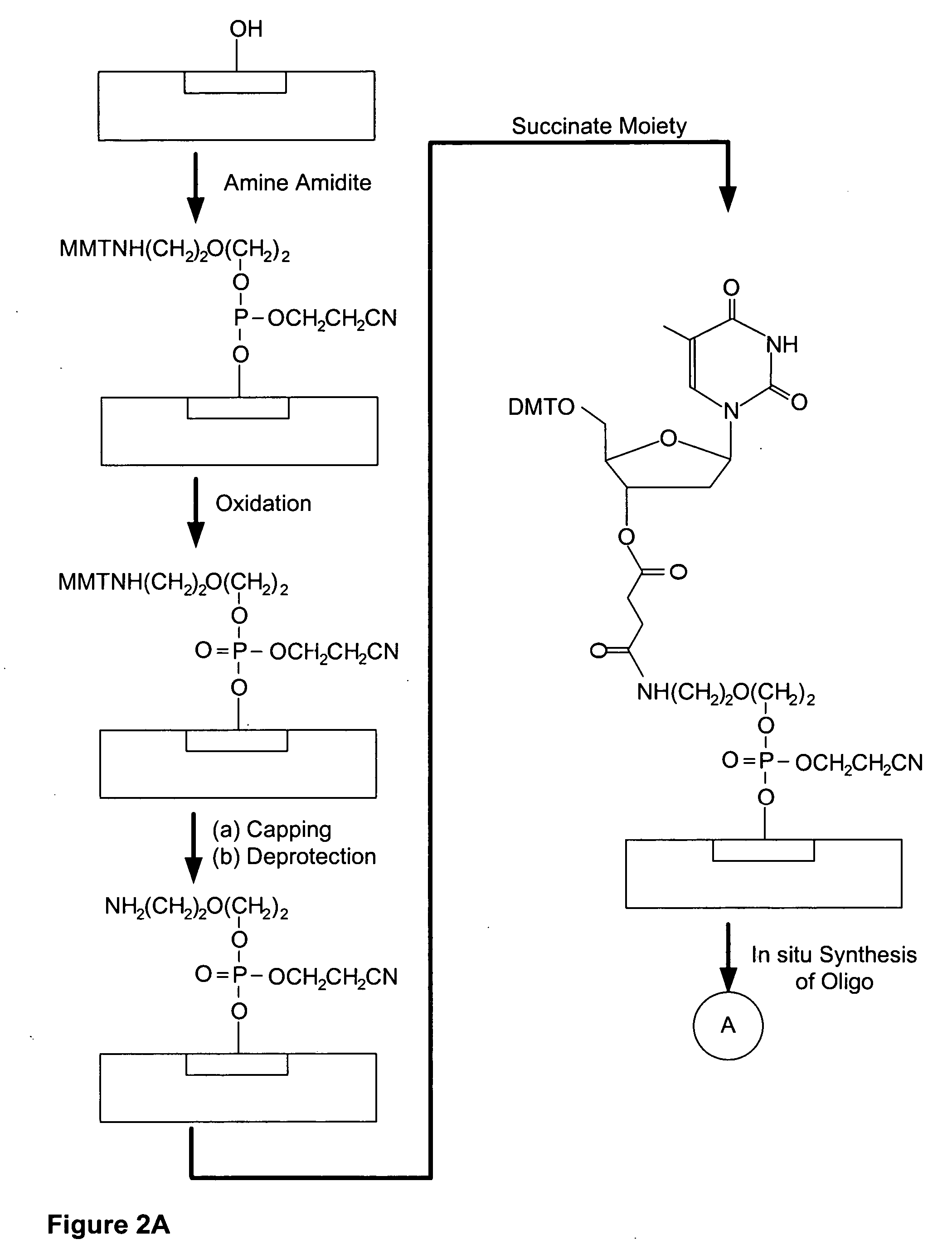

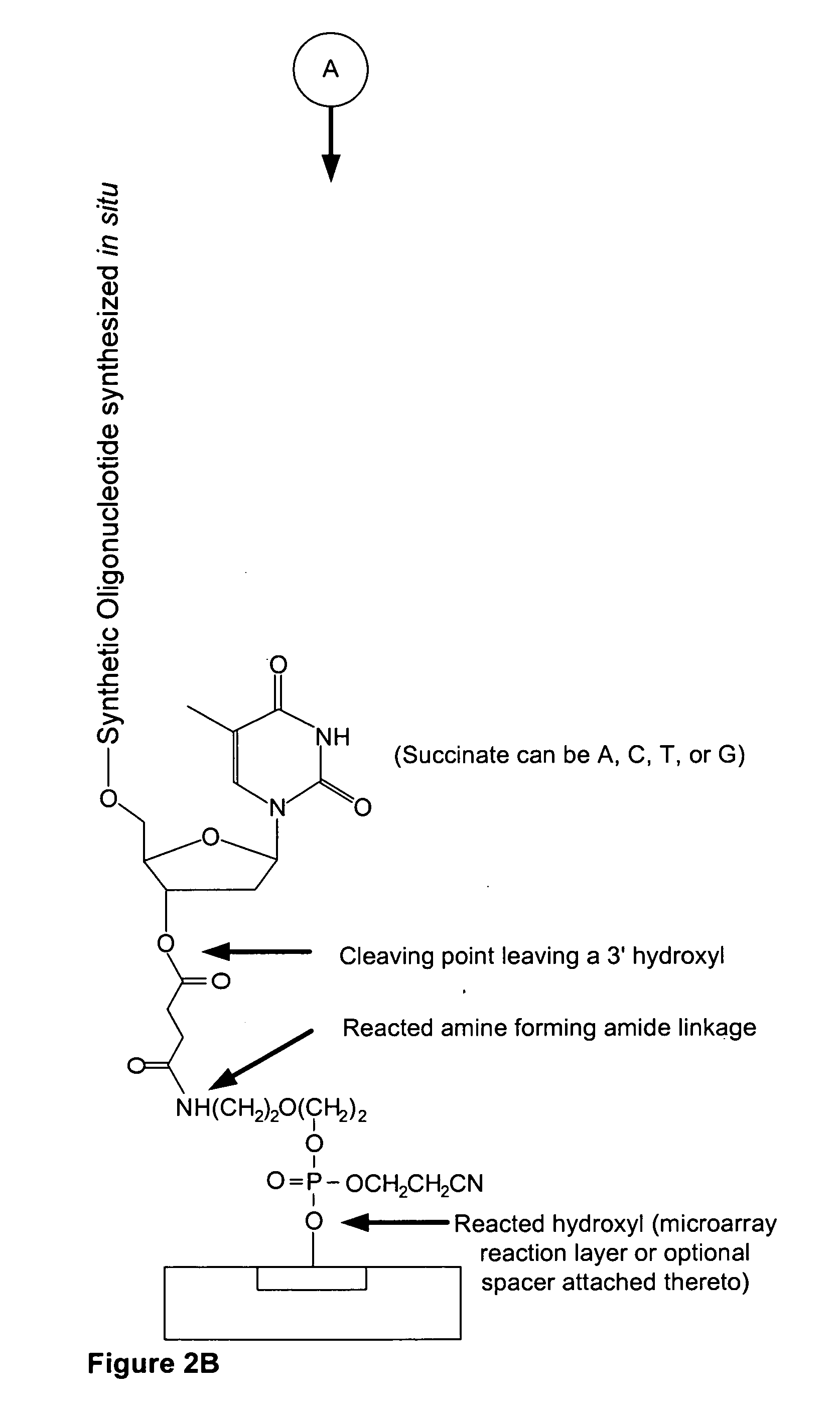

Cleavable Linker using Amino Amidite and T-succinate

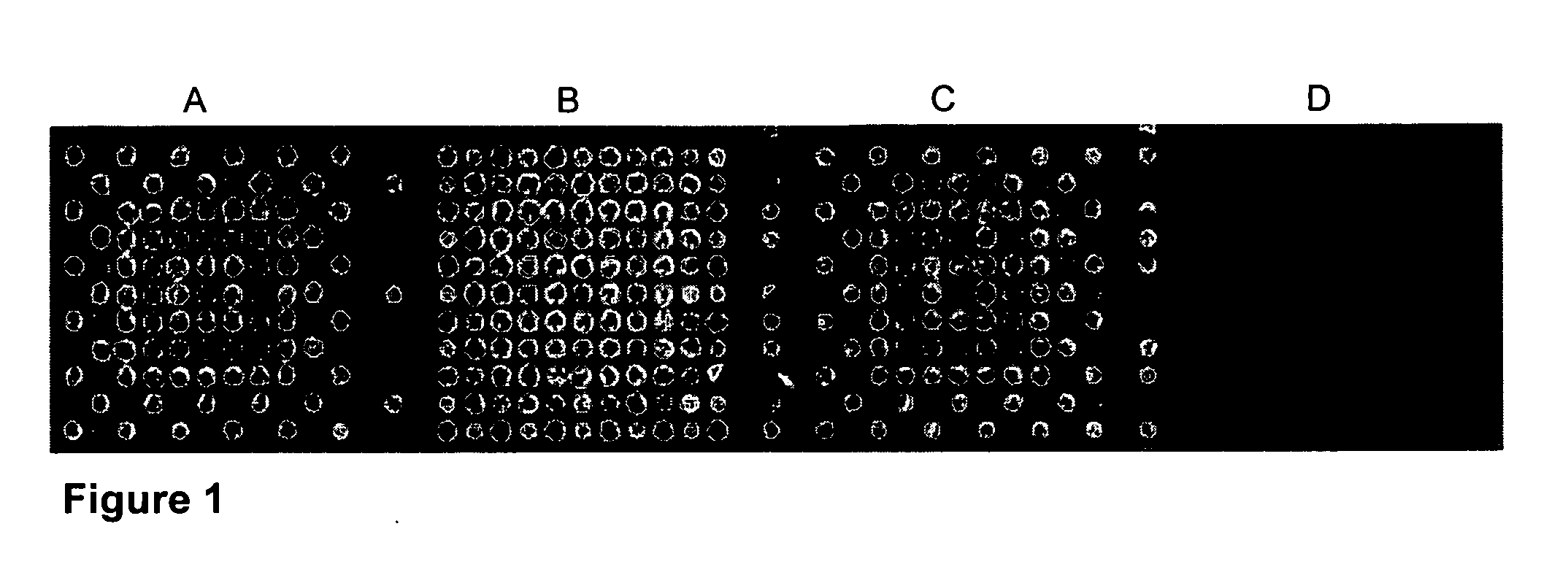

[0138] In this example, a CombiMatrix CustomArray™ 12K microarray was used to synthesize oligonucleotides attached to the microarray through a base-cleavable linker. The microarray had approximately 12,000 platinum electrodes on a solid surface having a porous reaction layer, wherein each electrode was electronically addressable via computer control. The oligonucleotides were DNA and were synthesized in situ using electrochemical synthesis at locations associated with the electrodes on the microarray. Electrochemical synthesis used standard phosphoramidite chemistry coupled with electrochemical deblocking of the protecting groups on the synthesized DNA for the addition of each nucleotide contained in the oligonucleotide. For attachment of the phosphoramidites, the microarray had organic reactive hydroxyl groups that allowed attachment of the first phosphoramidite. Electrochemical deblocking involved turning on an electrode to gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com