Apparatus to treat a substrate and method thereof

a technology of apparatus and substrate, applied in the direction of electrical apparatus, basic electric elements, electric discharge tubes, etc., can solve the problems of conventional methods, cation beams may not be properly neutralized in the center, and undercutting known as defective etching,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Reference will now be made in detail to the embodiments of the present general inventive concept, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present general inventive concept by referring to the figures.

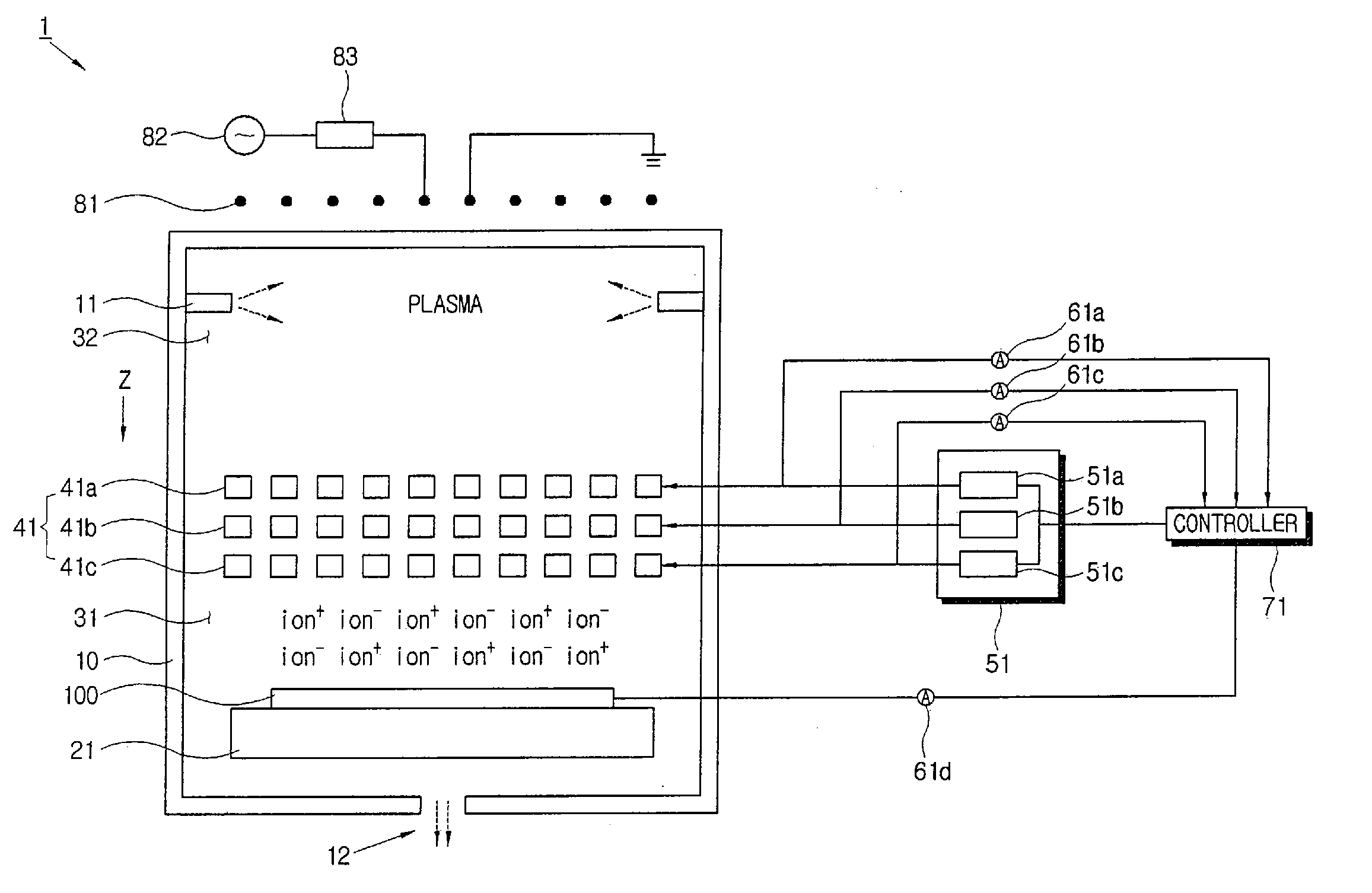

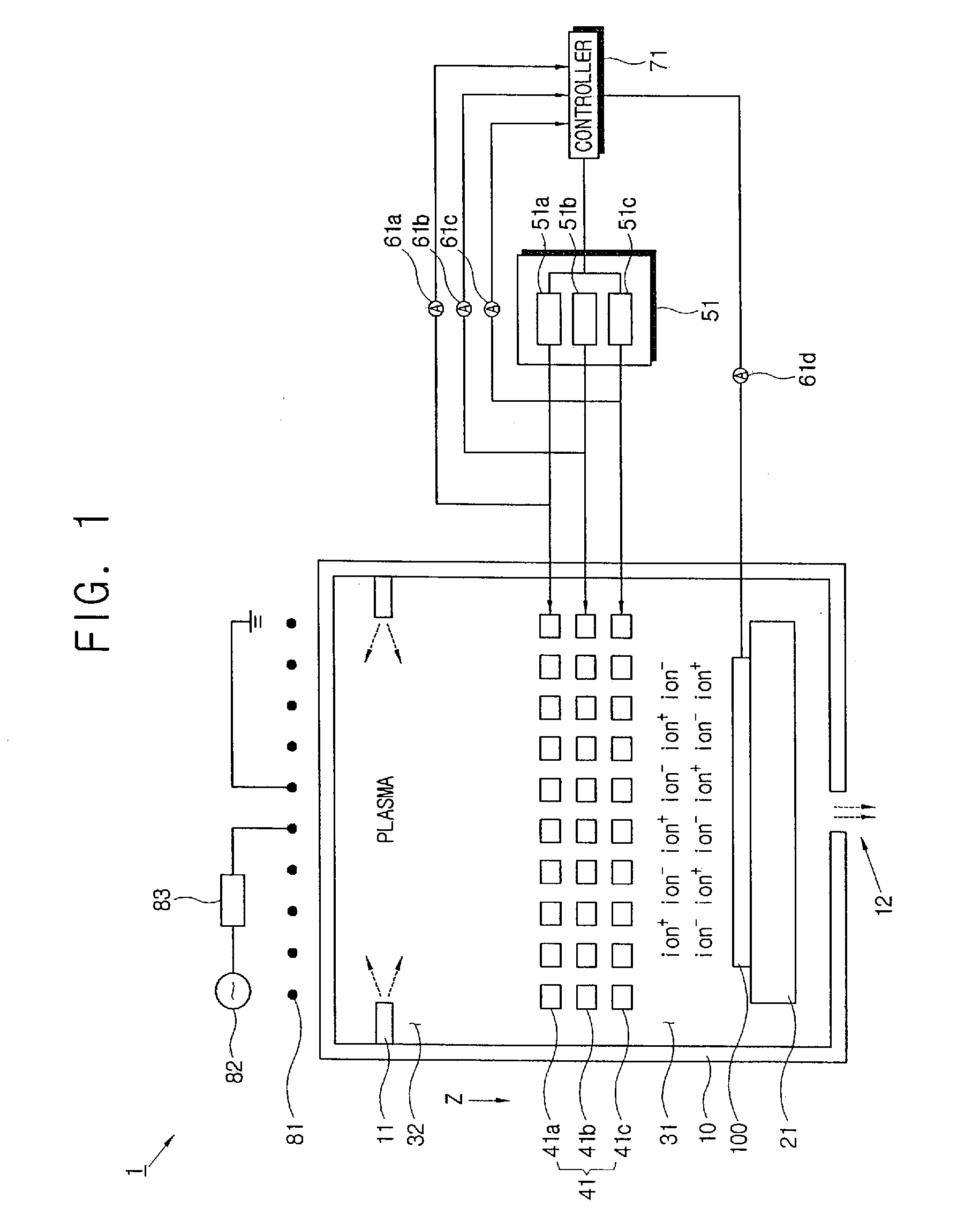

[0048]FIG. 1 is a sectional view illustrating an apparatus 1 to treat a substrate 100 according to an exemplary embodiment of the present general inventive concept.

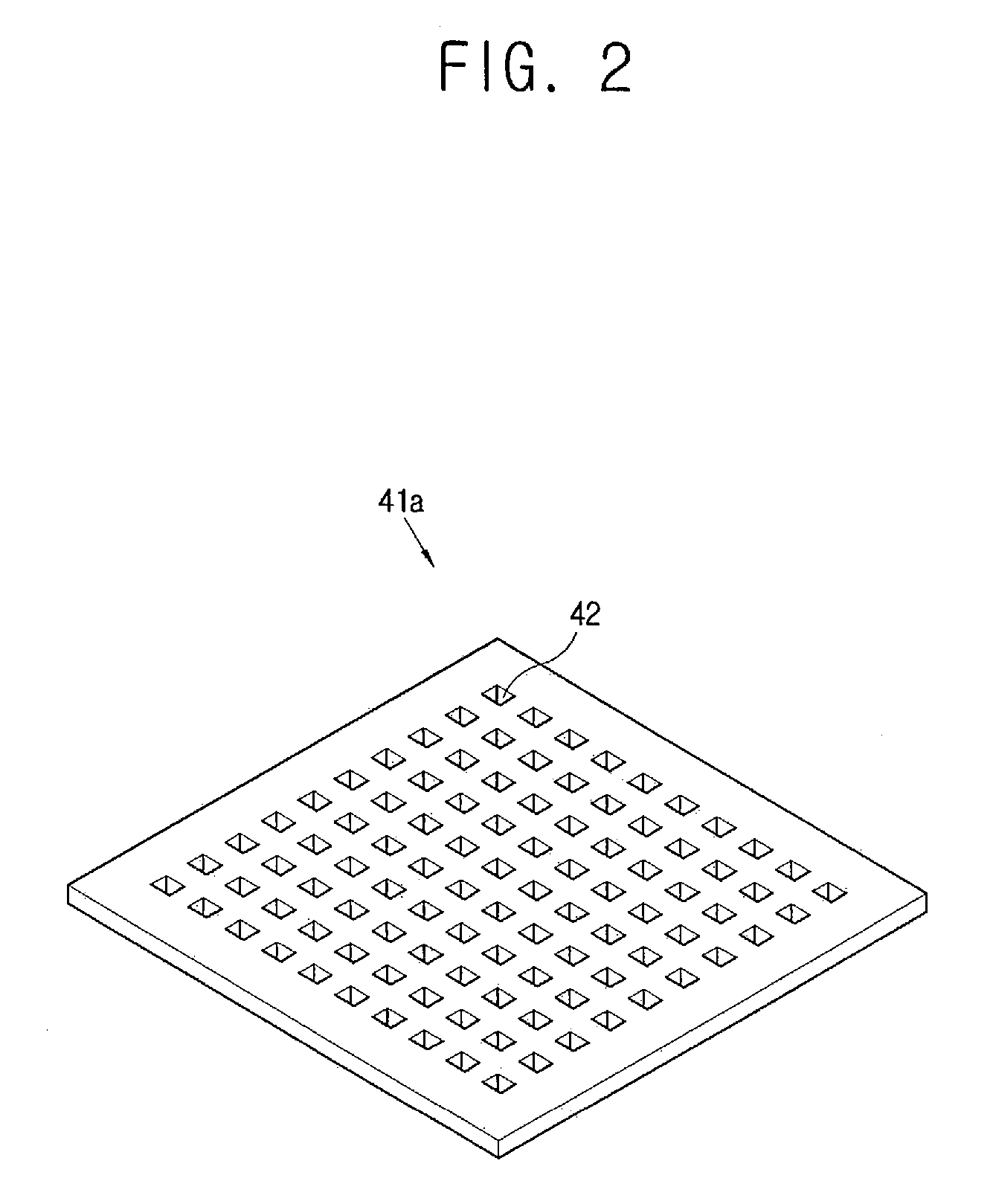

[0049] The apparatus 1 to treat the substrate 100 comprises a vacuum chamber 10 having a treating space 31 and a plasma space 32 formed therein, a table 21 on which the substrate 100 to be treated is placed, an extract electrode 41 to extract a cation beam and a negative charge beam from plasma, and a coil 81 and a plasma forming power supply 82 which form the plasma. The extract electrode 41 is connected to a power supply 51, and electric power supplied to the extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com