Refrigeration system with bypass subcooling and component size de-optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

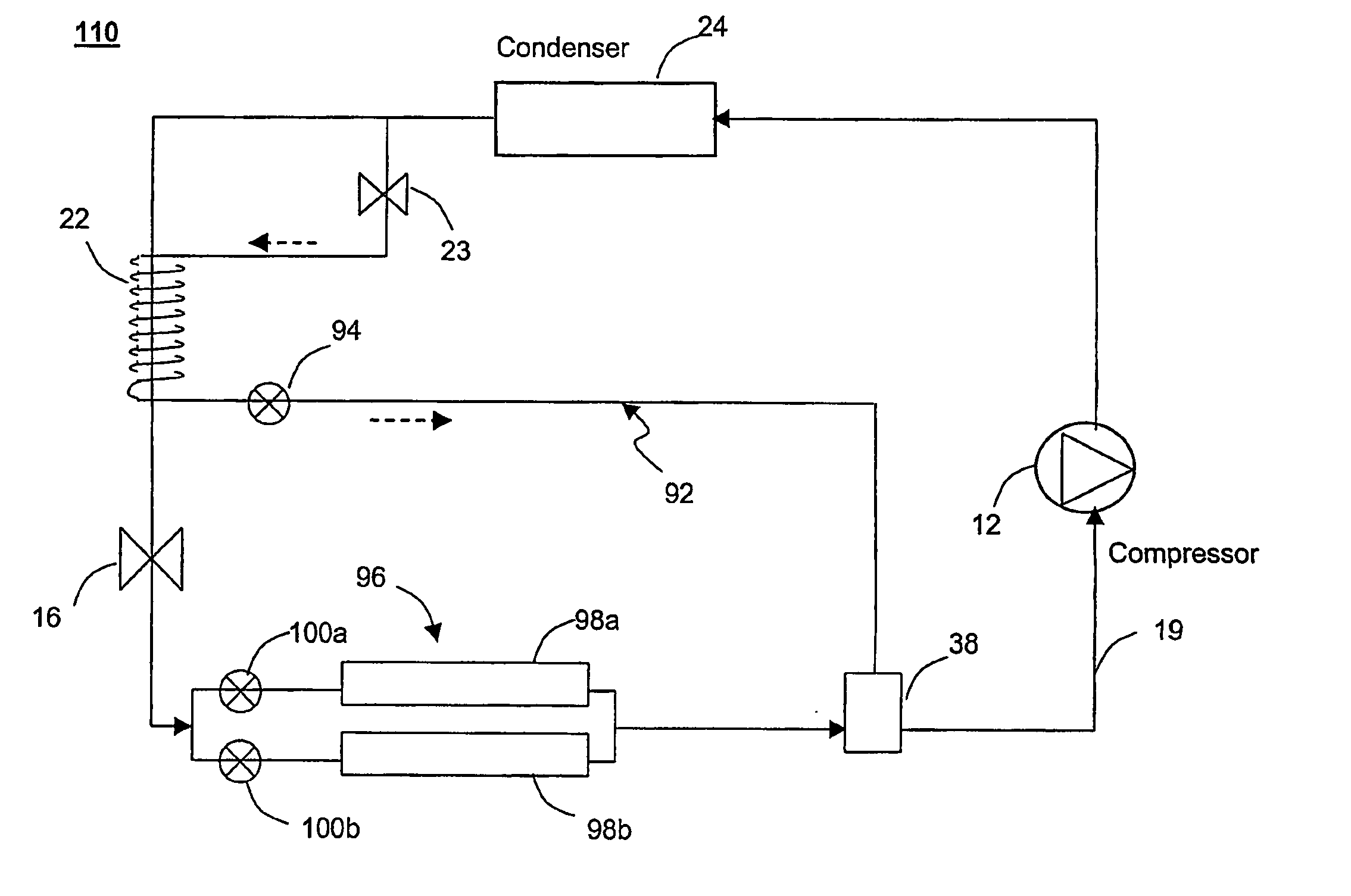

[0066]FIG. 5 shows a bypass technology concept, where a portion of liquid refrigerant is bypassed through a bypass line or path 27. The refrigerant in the bypass path goes through a secondary expansion device 23, thus lowering its pressure and temperature. The cold refrigerant mixture after the secondary expansion device receives heat energy from the hot liquid refrigerant that has exited the condenser and is flowing through the primary refrigerant line, producing additional subcooling in the liquid refrigerant. The additional subcooling produced from this bypass method makes the subcooling process in the condenser unnecessary. Thus, FIG. 5 shows a smaller condenser 14b, where the subcooling section has been removed and is identified as a dotted rectangular box.

[0067]FIG. 6 shows that the bypass technology enables the use of a larger evaporator than the evaporator in an optimized system without the bypass technology. The use of the larger evaporator is possible because of the incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com