FCC process for the maximization of medium distillates

a medium distillate and fcc technology, applied in cracking process, catalytic cracking, petroleum industry, etc., can solve the problems of reducing catalyst-to-oil ratio (cto) as well as conversion, challenging to change the operation parameters of fcc, and catalytic cracking process runs in thermal balance, so as to improve the performance of zsm-5-based additives and reduce contact time. , the effect of increasing catalyst circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

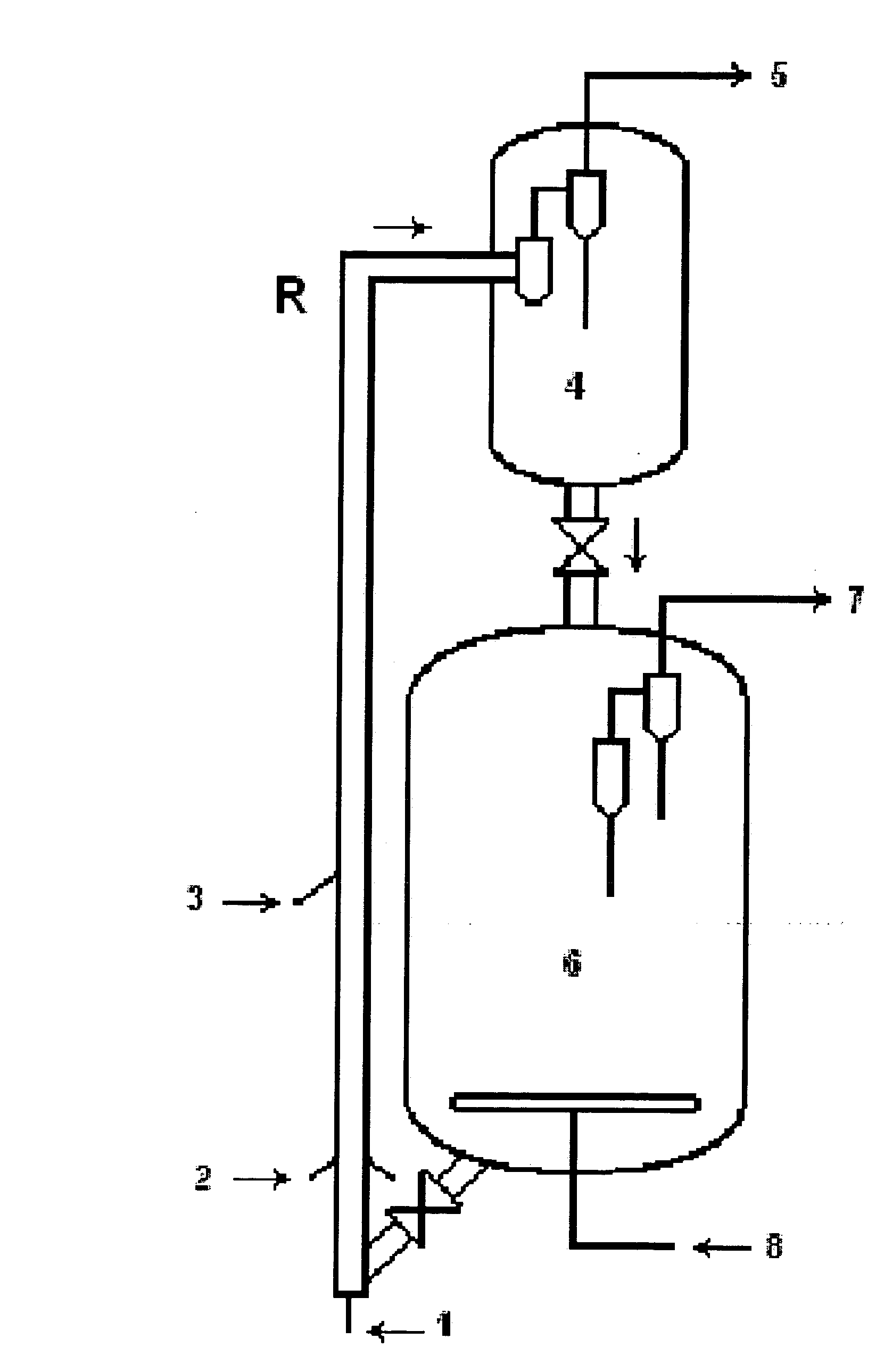

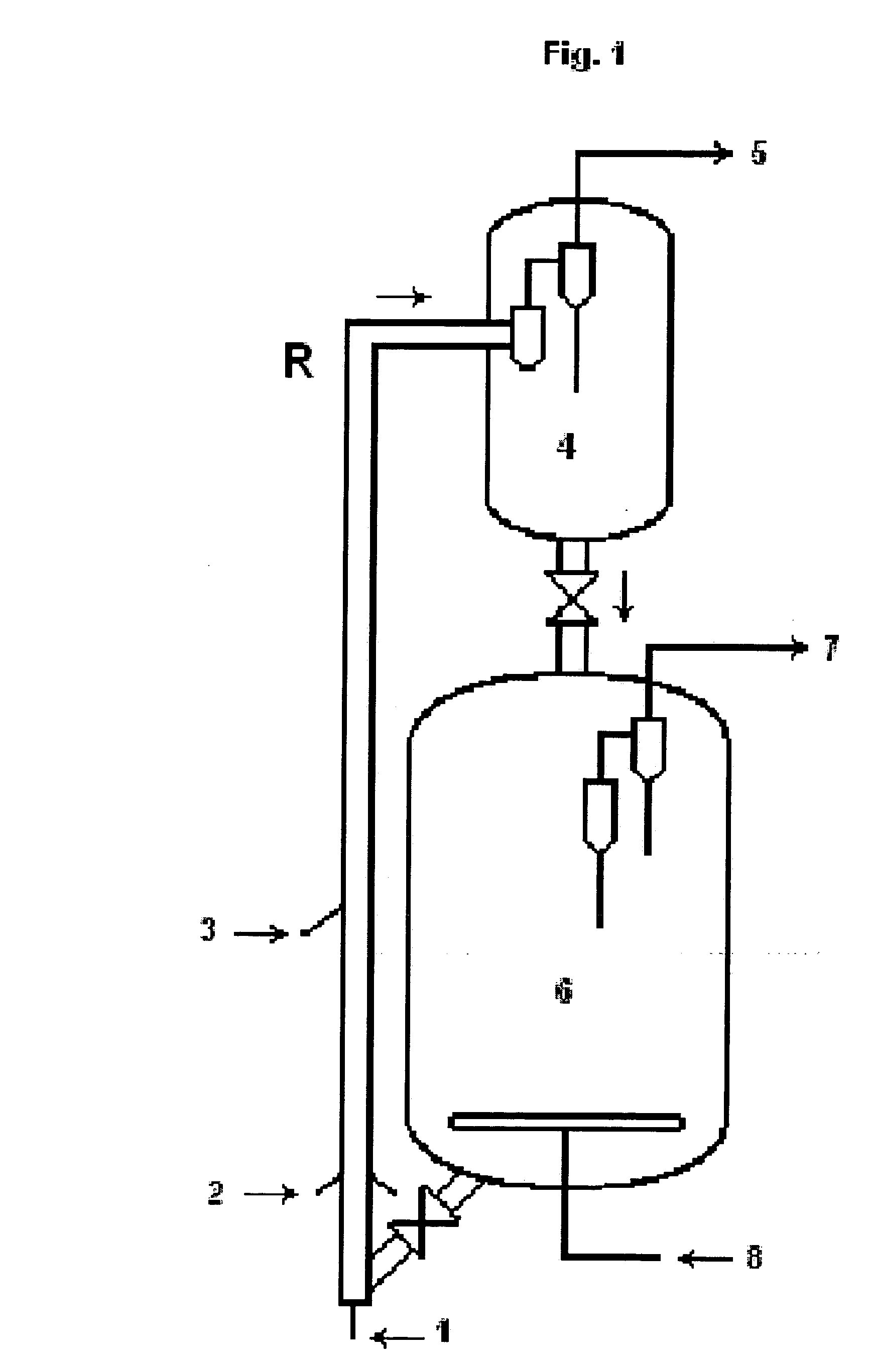

[0034] One series of tests is carried out in a FCC circulation prototype unit, for a feed rate 200 kg / h, catalyst inventory 200 kg, and working in thermal balance. Gasoleum of vacuum is used as feedstock from “Bacia de Campos”, which contains 18.7° API and 42% of aromatic compounds. The experiments are accomplished in the presence of an equilibrium catalyst containing 1.78% of rare earths, 1,779 ppm of vanadium, 2,481 ppm of nickel, about 1% of ZSM-5 crystal and 142 m2 / g of specific area.

[0035] The prototype unit riser has height 18 m with a feedstock axial injection mouth in the base. An auxiliary line, also in the riser base, and a second injection point located at 3 m from the base can be used optionally for introducing water or naphtha. The naphtha used as coolant contains 22% of aromatic compounds and a final distillation boiling point of 205° C.

[0036] All analyses of the aromatic compounds content are carried out employing the Super Critical Chromatography technique of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com