Sealed container and manufacturing method thereof

a technology of sealing container and manufacturing method, which is applied in the direction of rigid containers, packaging, bottles, etc., can solve the problems of large use amount of metal material, large cost increase in the whole container, and difficulty in seaming process, so as to improve the recyclability of containers and improve the filling speed and transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

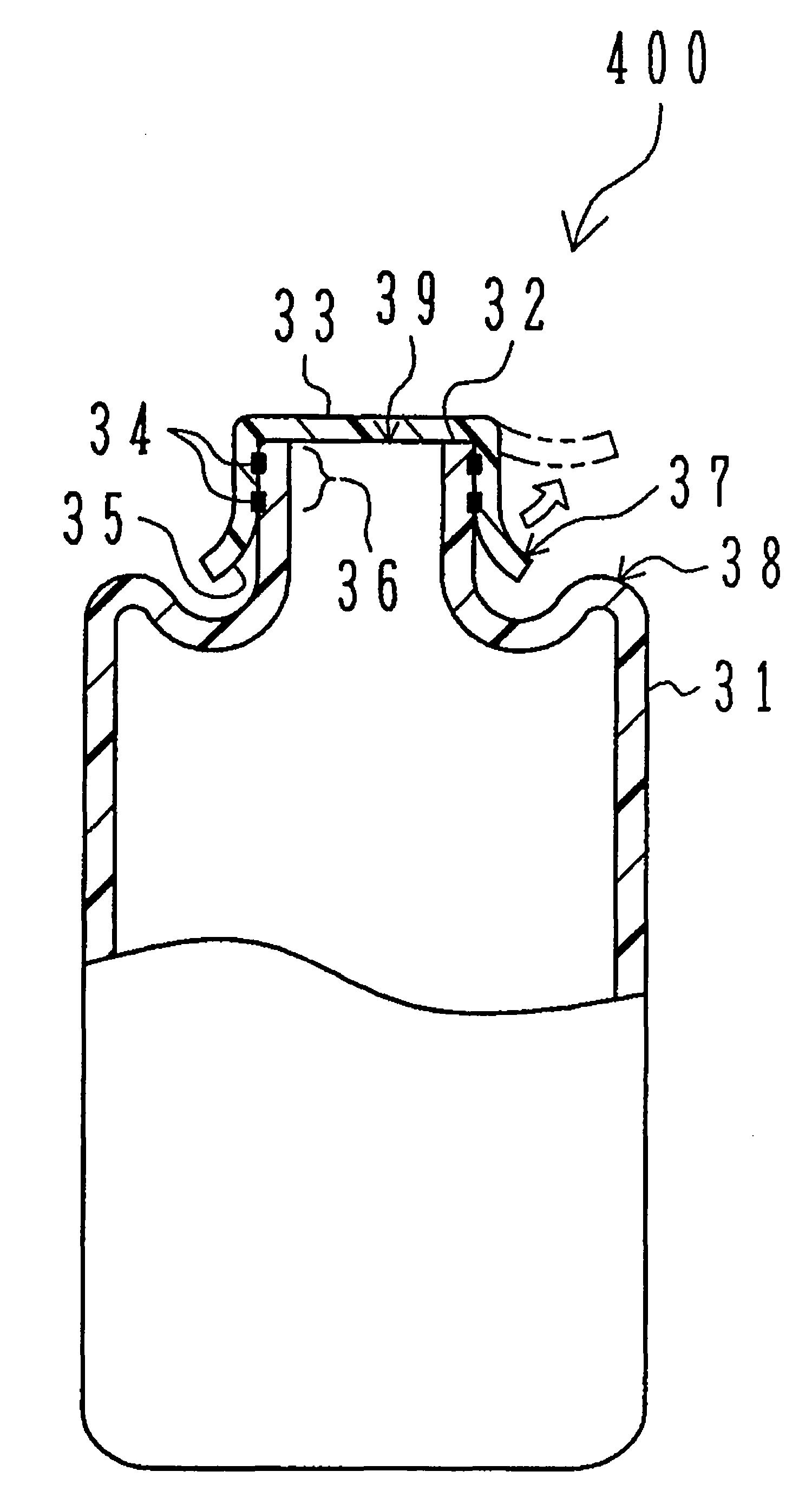

first embodiment

[0056] So long as the above-described connecting structure is satisfied, the shape of the lid portion and the shape of the container body, in particular the shape of the opening can be suitably changed. In the sealed container 100 of the first embodiment, the container body 1 has a shape in which the wall thereof is folded toward the inside of the container, and the opening 9 is formed at a position which is lower than the height of the folded portion. By giving the container body 1 this kind of shape, it forms a shape in which a straw can be easily inserted in the opening 9 at the time the lid is opened. The lid portion 3 has a size which at least covers the opening 9 in order to make it possible to seal the opening 9, and is formed so as to follow the shape of the outer wall surface of the container body 1 surrounding the opening 9. In this way, bonding surfaces which form the connected portion that forms the welded portion 4 are formed.

[0057] The outer edge portions of the openin...

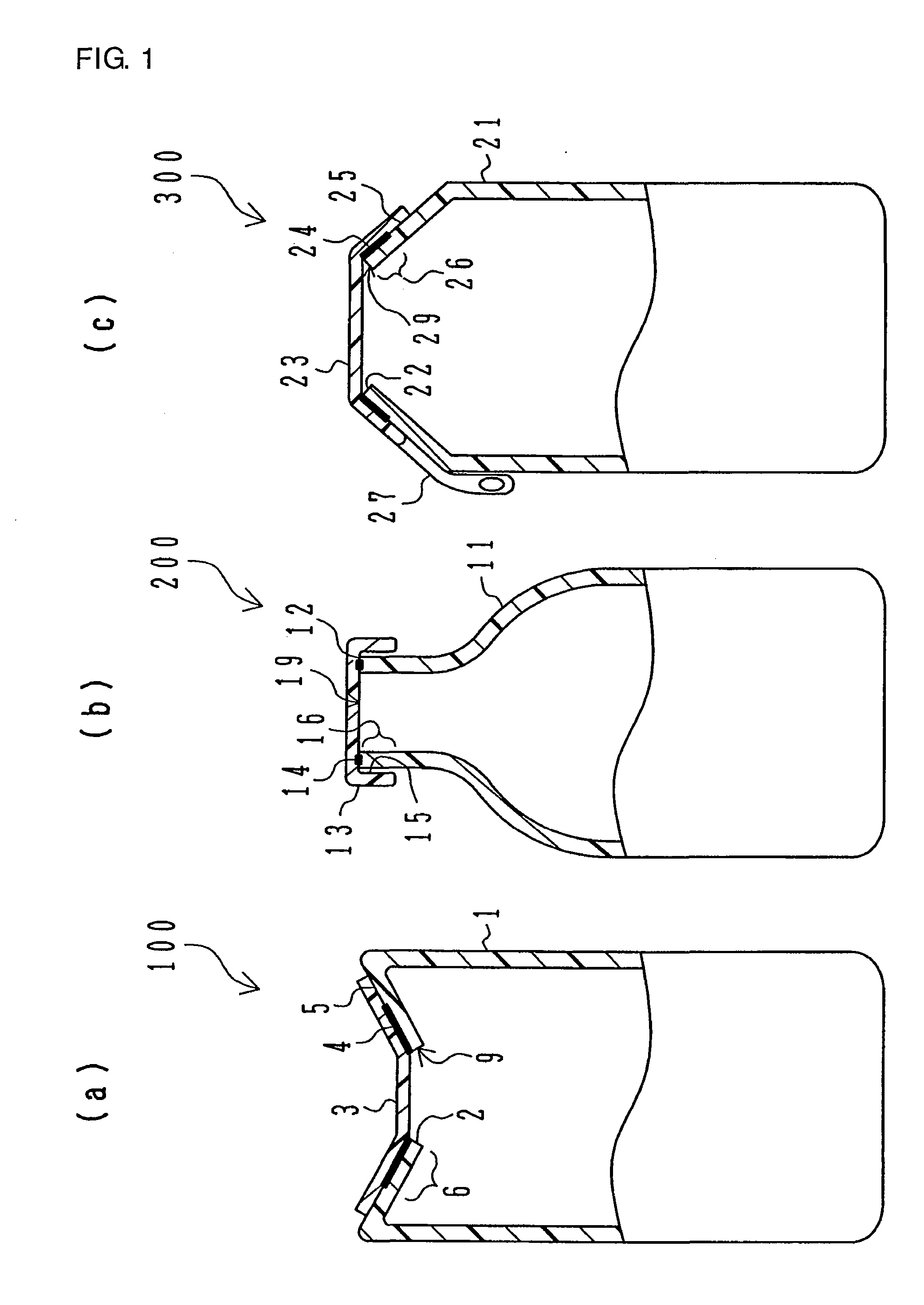

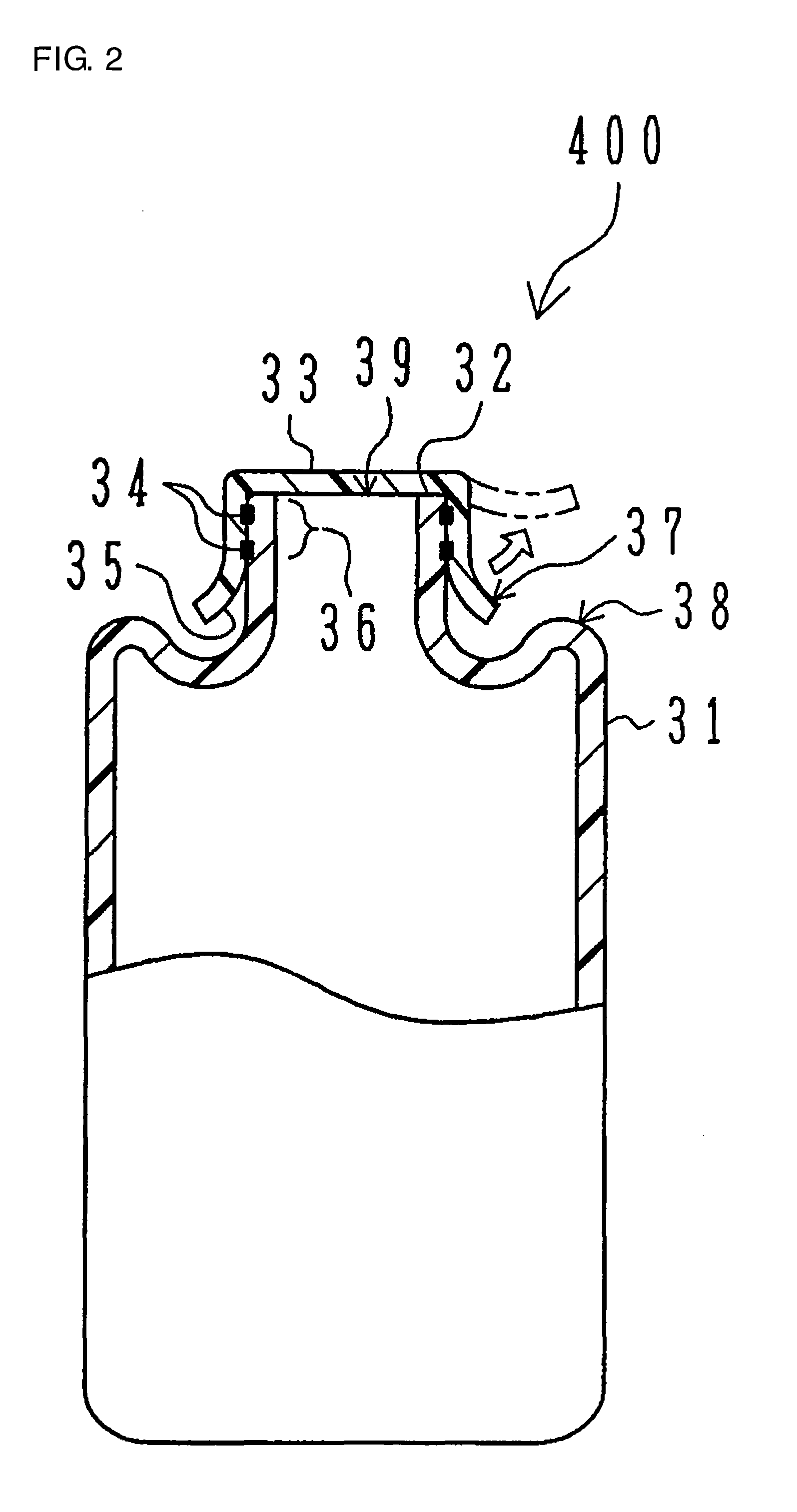

second embodiment

[0073] On the other hand, in the case where the sealed container 200 is manufactured, after forming bonded surfaces by bonding an edge surface of the opening and an inner wall surface of the lid portion in order to make it possible for at least an inner wall surface of the peripheral portion of the opening from the inner wall surface of the container body to make contact with the container contents, the bonded surfaces are irradiated with a laser to form a welded portion.

[0074] In this regard, a process which provides a laser light absorbing portion in at least one of an outer wall surface of the peripheral portion of the opening or an inner wall surface of the lid portion, or in at least one of an edge surface of the opening or an inner wall surface of the lid portion, is preferably provided. Even if there are contours or undulations along the absorbing portion which make mechanical contact complicated, laser welding can be carried out with good precision. This is because the lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Light | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com