Field effect transistor

a field effect transistor and transistor technology, applied in the field of field effect transistors, can solve the problems of increased specific on-state resistance and circuit breakage, and achieve the effect of low specific on-state resistance and high work function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

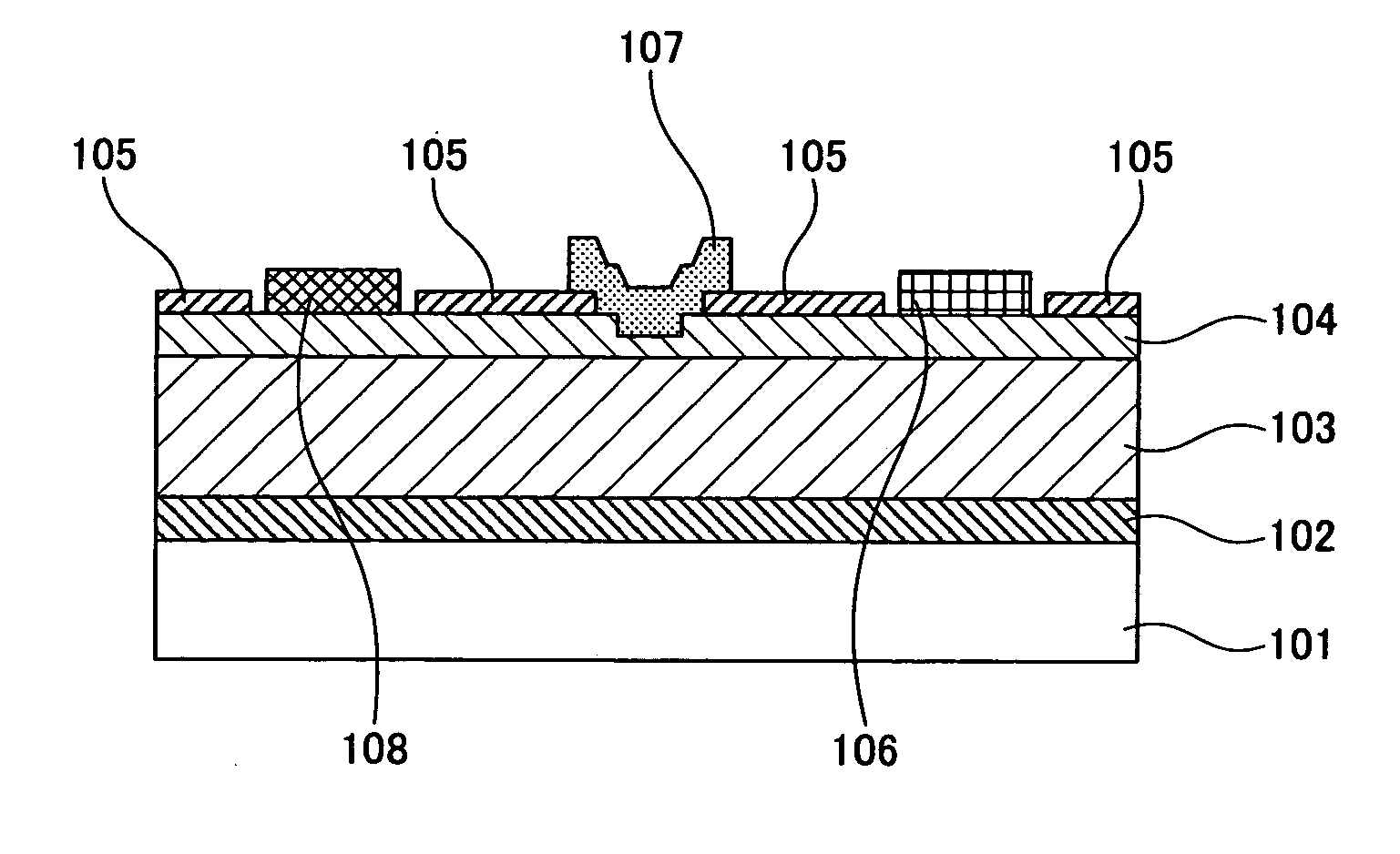

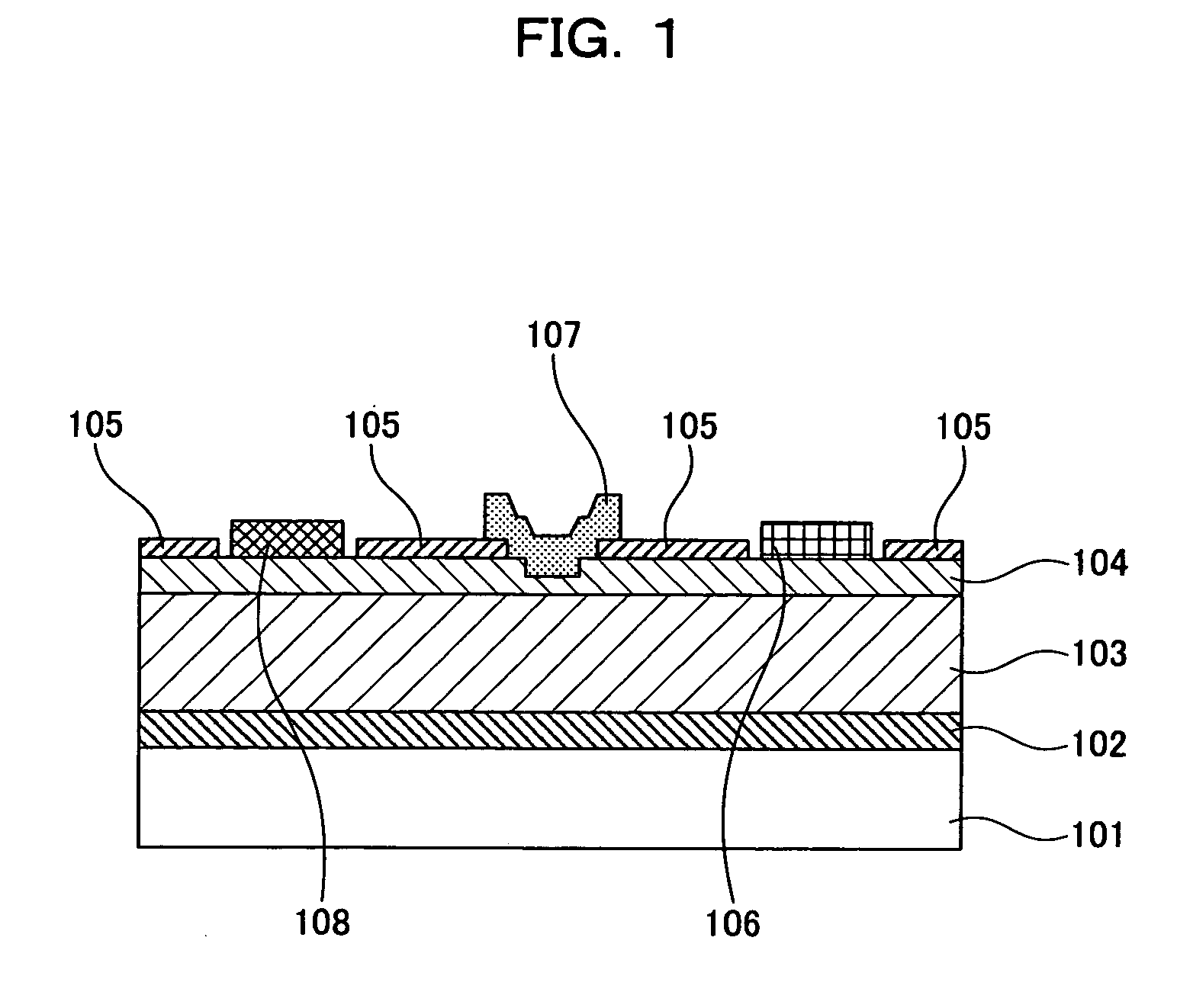

[0046]FIG. 1 is a sectional view showing a field effect transistor using a conductive oxide for a gate electrode according to Embodiment 1 of the present invention.

[0047] In FIG. 1, reference numeral 101 denotes a sapphire substrate, reference numeral 102 denotes an AlN buffer layer, reference numeral 103 denotes a first undoped GaN layer, reference numeral 104 denotes a first undoped AlGaN layer, reference numeral 105 denotes a SiO2 thin film, reference numeral 106 denotes a Ti / Al drain electrode, reference numeral 107 denotes a ZnInSnO gate electrode, and reference numeral 108 denotes a Ti / Al source electrode.

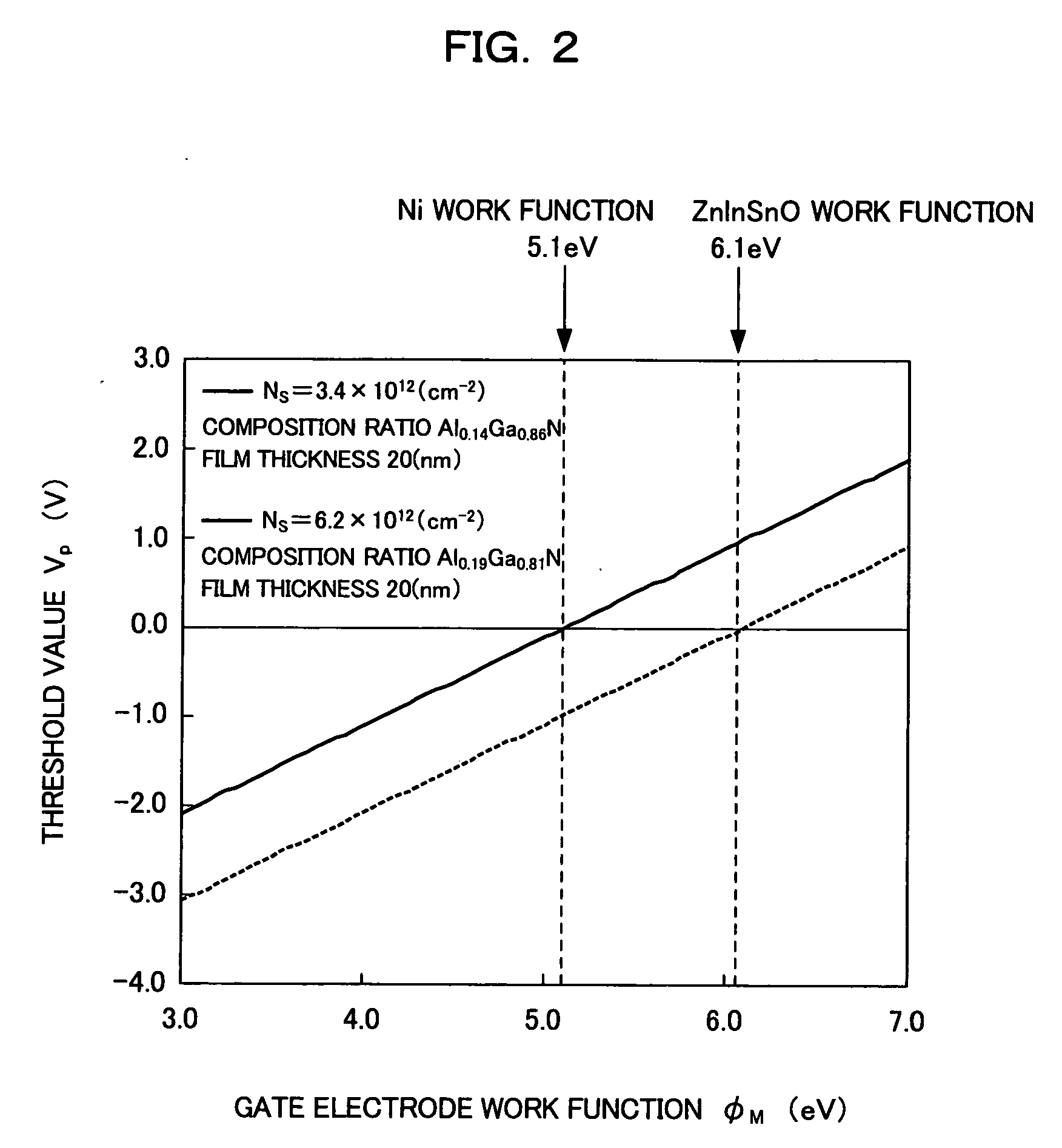

[0048]FIG. 1 shows the configuration of the field effect transistor of so-called normally-off type according to Embodiment 1. A threshold voltage VP is larger than 0 V. The feature of this configuration is the use of ZnInSnO for the gate electrode. In this configuration, the AlN buffer layer 102 having a thickness of 0.5 μm, the first undoped GaN layer 103 having a thicknes...

embodiment 2

[0059]FIG. 4 is a sectional view showing a field effect transistor using a conductive oxide for a gate electrode according to Embodiment 2 of the present invention.

[0060] In FIG. 4, reference numeral 401 denotes an n-type Si substrate, reference numeral 402 denotes an AlN buffer layer, reference numeral 403 denotes a first undoped GaN layer, reference numeral 404 denotes a first undoped AlGaN layer, reference numeral 405 denotes a Ti / Al drain electrode, reference numeral 406 denotes a ZnInSnO gate electrode, reference numeral 407 denotes a Ti / Al source electrode, reference numeral 408 denotes a Au wire, reference numeral 409 denotes a via hole, and reference numeral 410 denotes an Al backside source electrode.

[0061]FIG. 4 shows the configuration of the field effect transistor using the ZnInSnO gate electrode 406 according to Embodiment 2. In this configuration, the AlN buffer layer 402 having a thickness of 200 nm, the first undoped GaN layer 403 having a thickness of 1 μm, and th...

embodiment 3

[0066]FIG. 6 is a sectional view showing a field effect transistor using a conductive oxide for a gate electrode according to Embodiment 3 of the present invention.

[0067] In FIG. 6, reference numeral 601 denotes a GaN substrate, reference numeral 602 denotes a first undoped GaN layer, reference numeral 603 denotes a first undoped AlGaN layer, reference numeral 604 denotes a Ti / Al drain electrode, reference numeral 605 denotes an AlGaNOx oxide layer, reference numeral 606 denotes a ZnInSnO gate electrode, and reference numeral 607 denotes a Ti / Al source electrode.

[0068]FIG. 6 shows the structure of the field effect transistor using ZnInSnO for the gate electrode according to Embodiment 3. In this structure, the first undoped GaN layer 602 having a thickness of 5 μm and the first undoped AlGaN layer having a thickness of 12 nm and are formed in this order on a plane (0001) of the GaN substrate 601. In this epitaxial layer, the composition ratio of the first undoped AlGaN layer 603 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com