Highly insulated exhaust manifold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

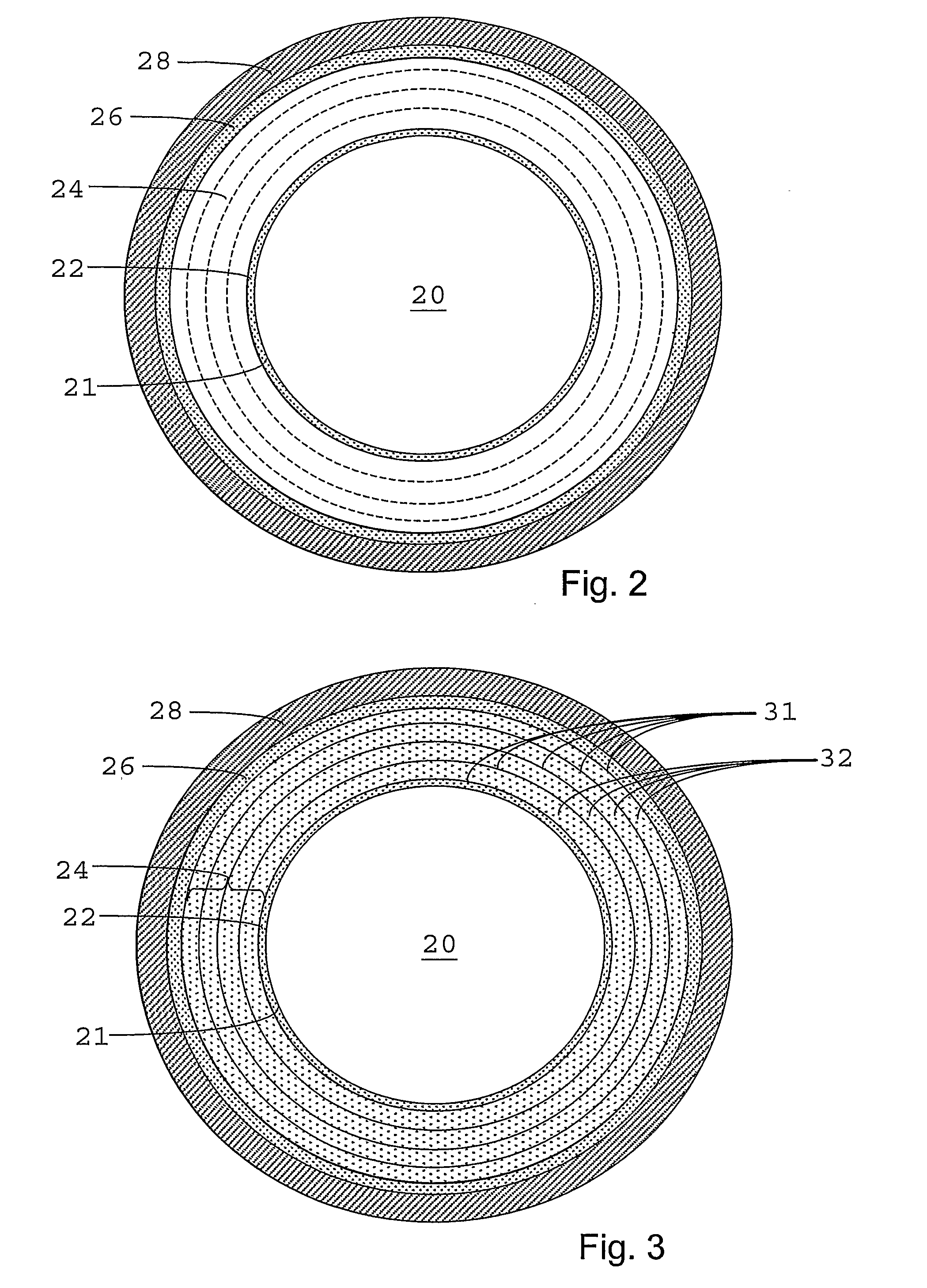

[0082] A series of 4-inch diameter disc composites were prepared in order to simulate the composite structure of an exhaust manifold having a composite insulation zone as described herein, and to demonstrate the improved insulative properties of such a composite structure. In all, four disc composites were prepared, three samples incorporating a composite insulation zone and a fourth sample that did not have a composite insulation zone. All four samples included an inner ceramic layer made by pouring a fused silica slip composition on a Plaster of Paris mold. The slip composition was product ICP-3 available from Industrial Ceramic Products, Marysville, Ohio. After the slip was dried each dried piece was fired in a ceramic kiln to cure the piece and form a finished inner ceramic layer. All four of the inner ceramic layers had a thickness of 0.265 inch.

[0083] Three separate composite insulation zones also were prepared. The first two consisted of alternating layers of aluminum foil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com