Steel manufacturing dust solidified, process for producing the same and production apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

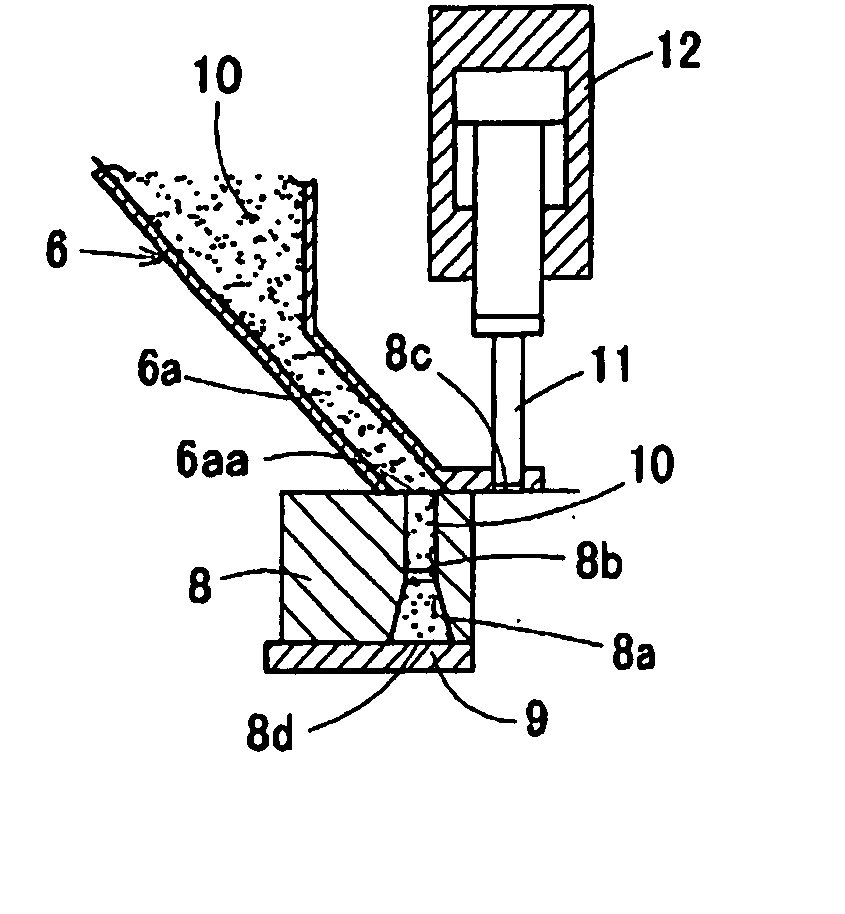

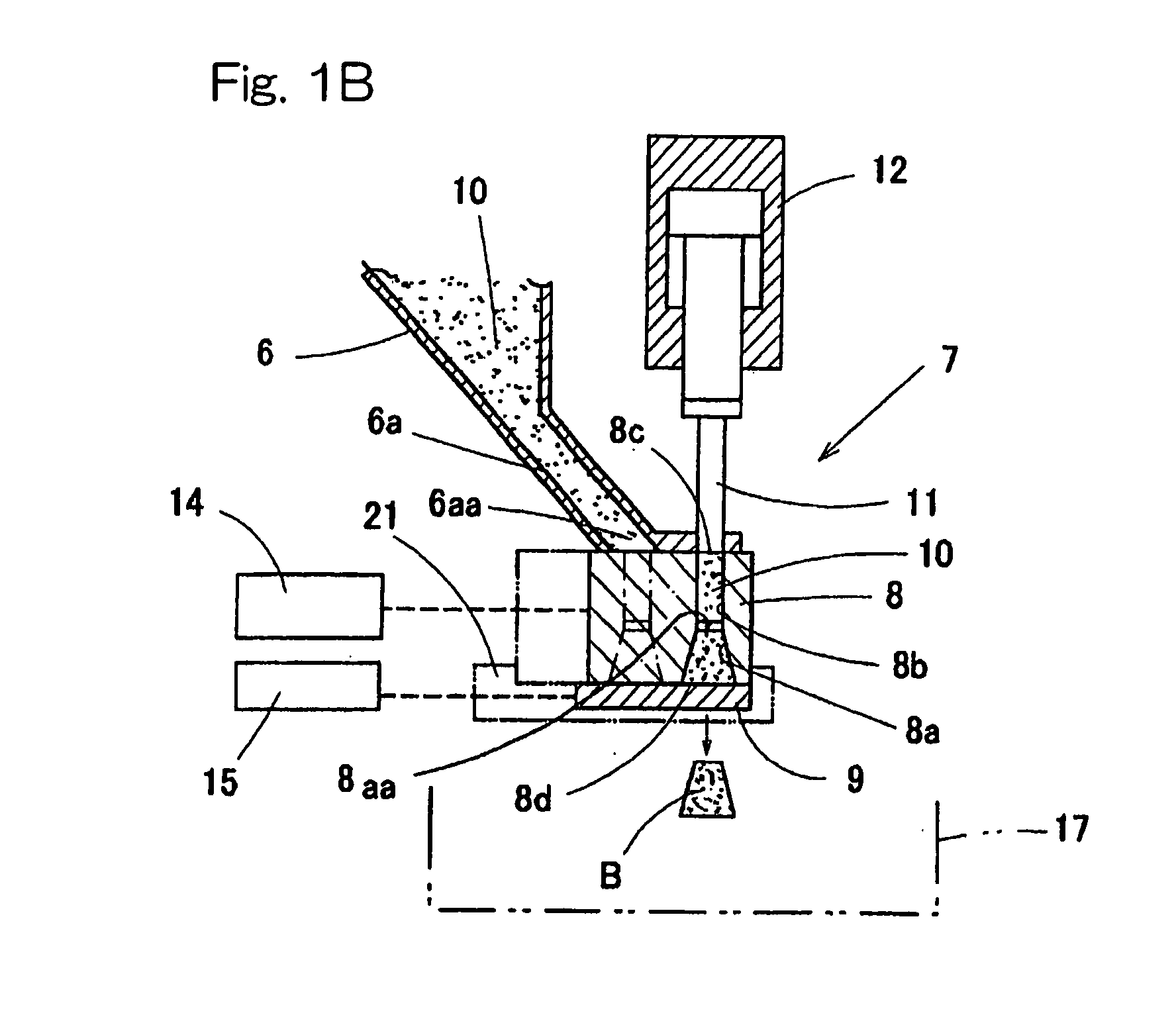

[0048] The steel manufacturing dust a and the carbon type powder d were mixed in a mixing ratio of 4:1 and pressured and molded within the previously described mold. The size of the steel manufacturing dust solidified was 71 mm in diameter, 58.5 mm in height and 696 grams in weight. In this example, a relatively quickly solidification was achieved.

example 2

[0049] Only the steel manufacturing dust was pressed and formed within the previously described mold after having been dewatered to a water content of 6 to 7% as a pretreatment. The size of the steel manufacturing dust solidified was 71 mm in diameter, 32 mm in height and 602 grams in weight. Even in this example, solidification was possible, but it was somewhat fragile.

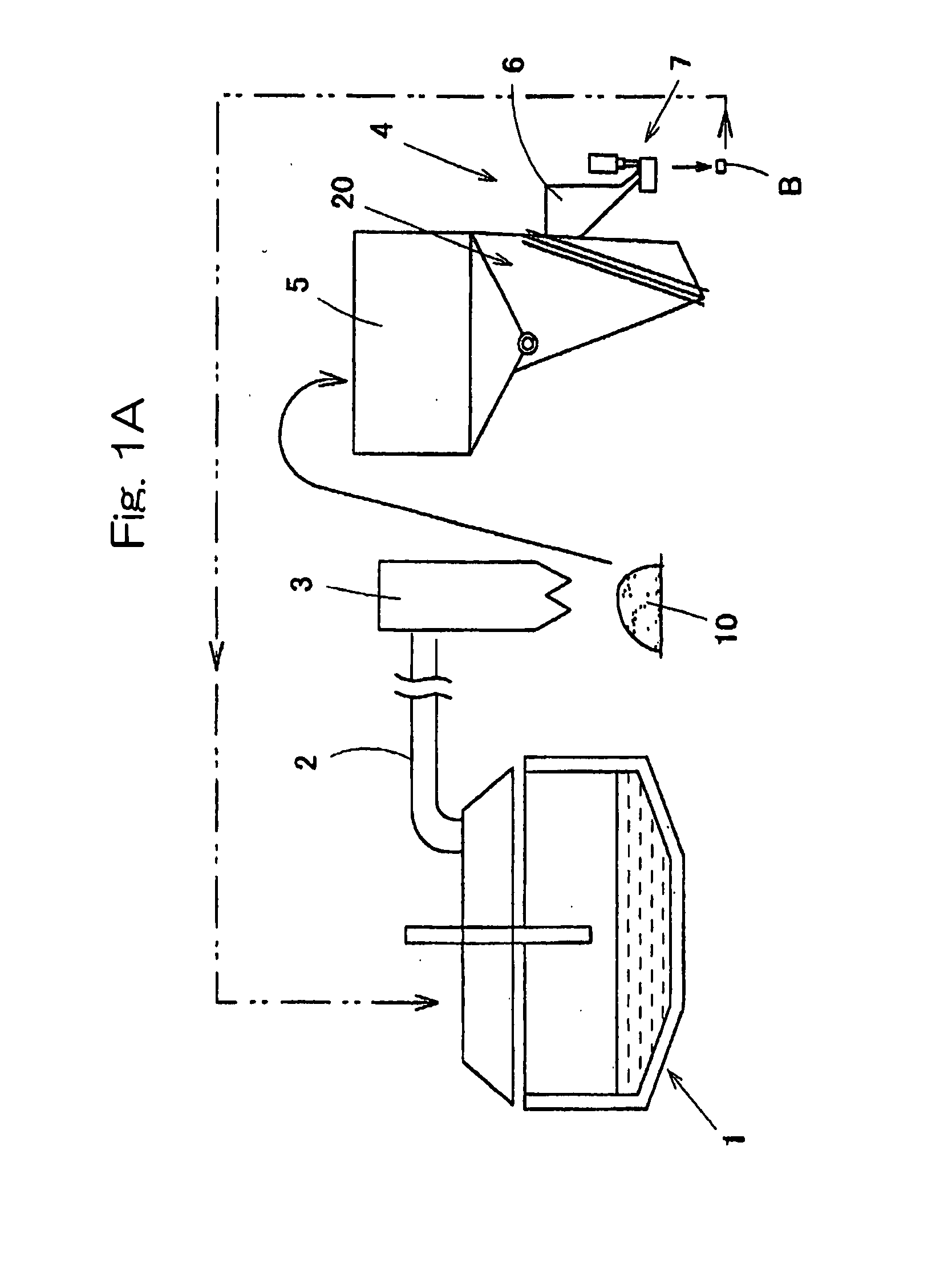

[0050] It is to be noted that although in the foregoing embodiment the dust occurring in the exhaust gases within the melting furnace 1 in the form of an electric furnace was used to manufacture the steel manufacturing dust solidified B, the steel manufacturing dust solidified B of the present invention and the dust used in the manufacturing process and apparatus thereof may suffice to be that containing as a principal component iron which occurs during the iron and steel manufacturing process or that occurring in a converter, a blast furnace or any other various type of steel manufacturing processes. Also, limited ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com