Tobacco material, flavoring agent, and regenerated tobacco material, reduced in stimulus and pungency in the smoking stage, method of preparing tobacco material and method of preparing flavoring agent

a technology of flavoring agent and tobacco material, which is applied in the field of improving the flavor and taste of tobacco, can solve the problems of undesired taste, unsatisfactory efficiency and cost, and undesired taste that has not yet been clarified, and achieve the effect of improving the flavor and taste of natural tobacco material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Analytical Method for the Present Causal Component

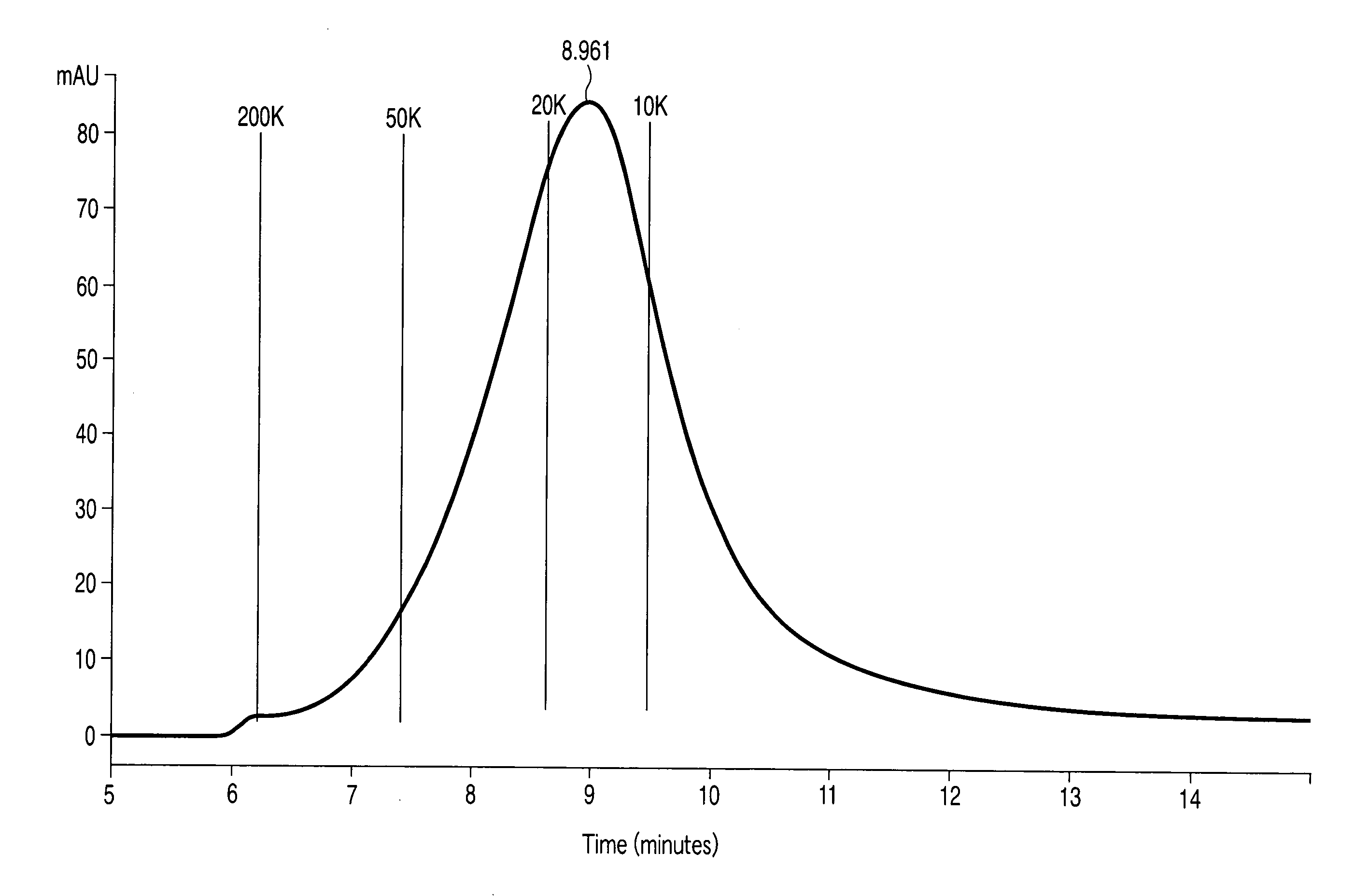

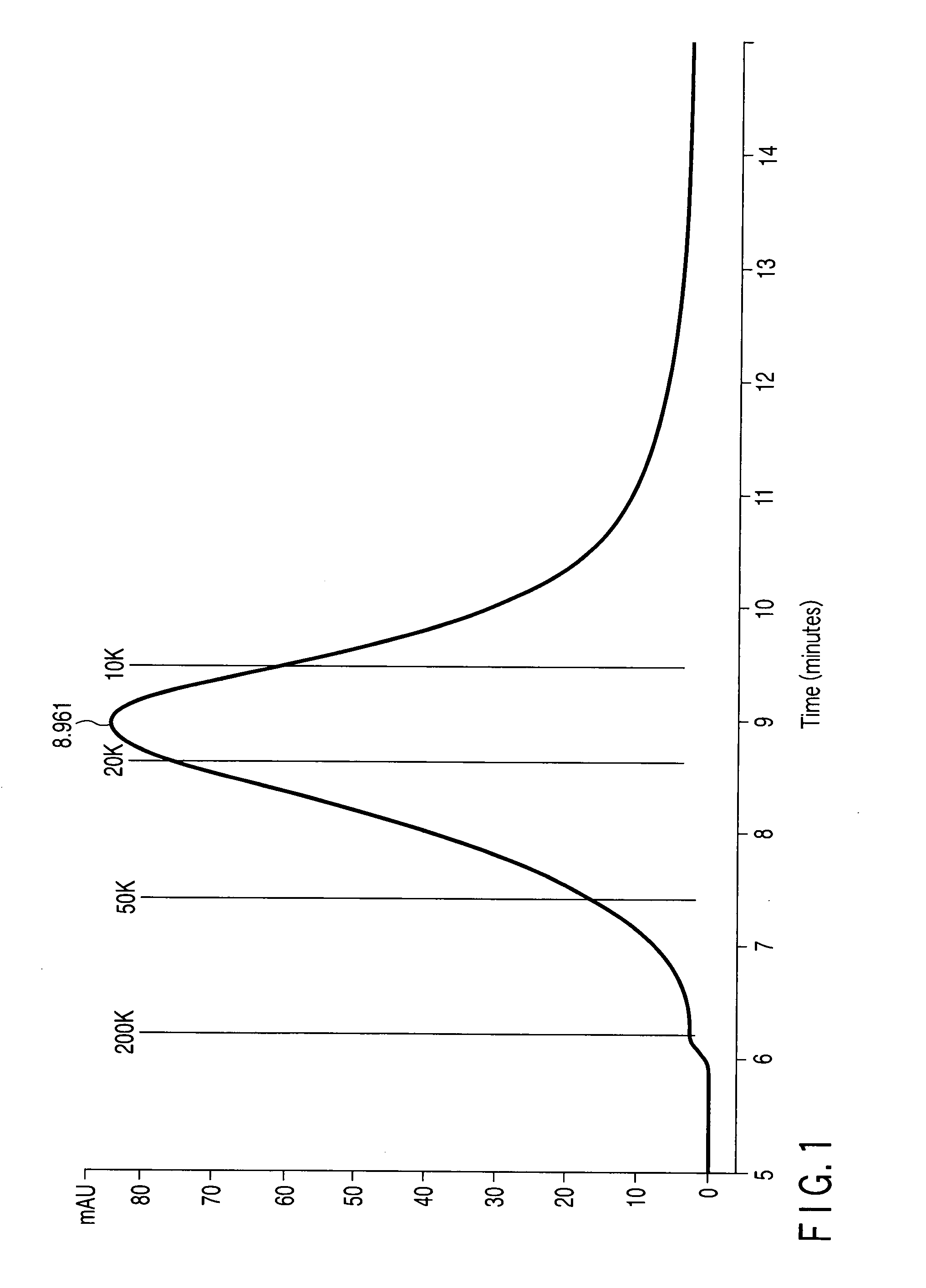

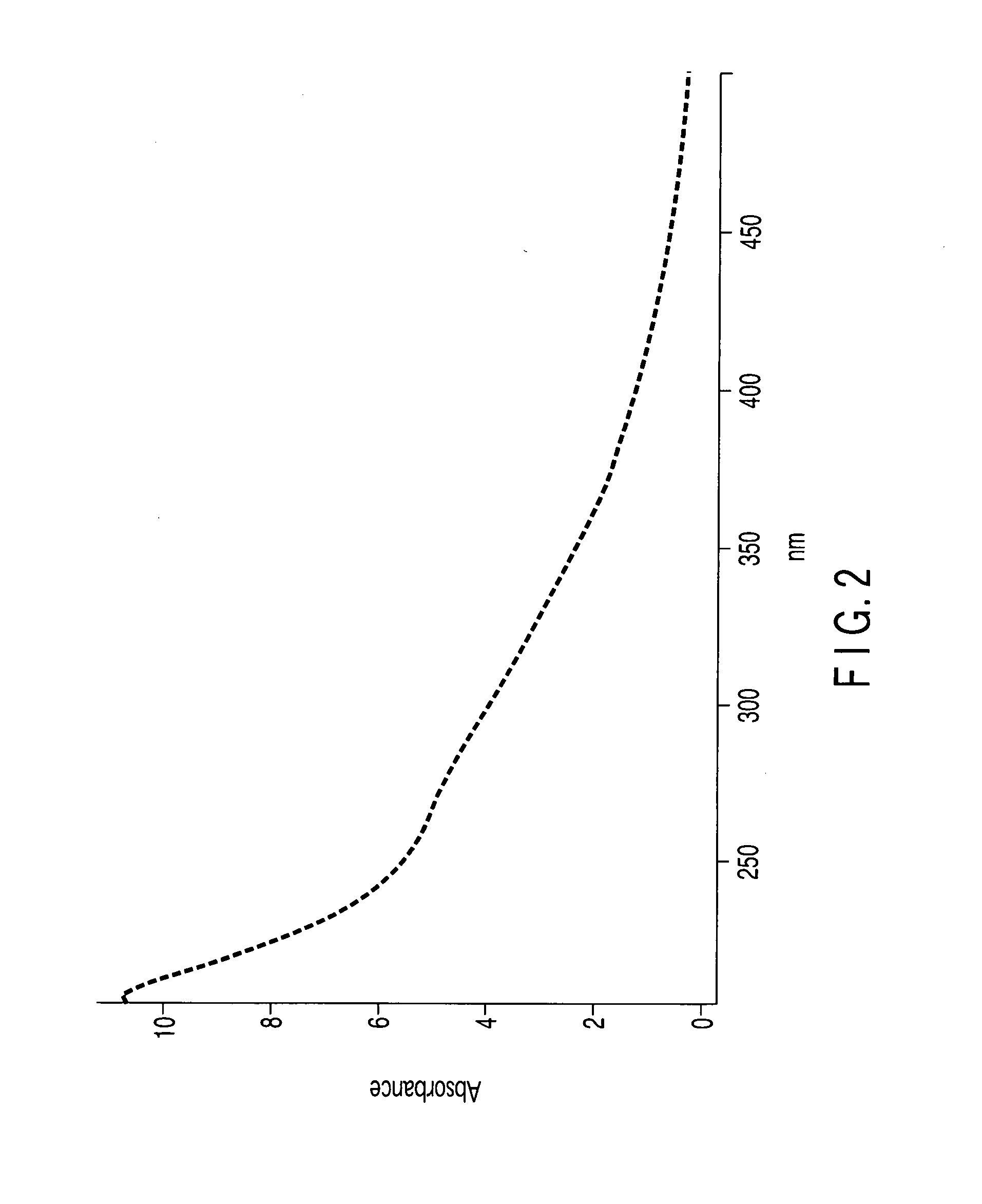

[0068] As an index of the decrease of the present causal component, a simple analytical method for the present causal component was established by using a high performance liquid chromatography. 1.0 g of Burley tobacco material (in the case of the extract liquid, pulverized was the extracted liquid, lyophilized one in an amount corresponding to 1.0 g of the tobacco material) was pulverized, to which 10 mL of 0.1M aqueous solution of sodium acetate was added. The mixture was stirred at room temperature for 30 minutes, filtered and subjected to centrifugal separation. The supernatant was passed into a reverse phase solid phase extraction cartridge (Oasis HLB (6 cc, 500 mg, Waters Inc.), washed with water and eluted with 10 mL of acetonitrile / water (6 / 4). The eluate was concentrated under a reduced pressure to remove the acetonitrile, passed into a mini column of a polyvinyl pyrrolidone resin (Polycler VT (Wako Junyaku K.K.)) and then ...

example 2

[0079] The filtrate (0.5 L, corresponding to 75 g of the raw material) obtained in the Reference Example was subjected to centrifugal separation (3,000 rpm, 10 minutes) so as to remove the insoluble portion and, then, subjected to an ultrafiltration treatment by using an ultrafiltration disk using a semipermeable membrane made of a regenerated cellulose having a fractionating molecular weight cutoff of 10,000 daltons (Ultracell PLGC ultrafiltration disk, Millipore Inc., nominal molecular weight cutoff of 10,000 daltons). The yields of the permeate and the concentrated liquid, after lyophilization, were 12.8 g and 2.1 g, respectively. The lyophilized material of the permeate was dissolved in 50 mL of water, and the total amount of the resultant solution was sprayed onto the shreds obtained in the Reference Example to obtain regenerated tobacco shreds. Cigarettes were made as in the Reference Example by using the regenerated tobacco shreds.

example 3

[0080] The filtrate (0.5 L, corresponding to 75 g of the raw material) obtained in the Reference Example was subjected to centrifugal separation (3,000 rpm, 10 minutes) so as to remove the insoluble portion, and added with 50 mL (volume of wet resin) of an anion exchange resin (DEAE Cellulofine available from Seikagaku Kogyo K.K.) to carry out adsorption by stirring, followed by filtration. The processed liquid was concentrated under a reduced pressure, and the total amount of the concentrate was sprayed onto the shredded tobacco obtained in the Reference Example to obtain regenerated tobacco shreds. Cigarettes were made as in the Reference Example by using the regenerated tobacco shreds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com