Reflection type liquid crystal display device and method of manufacturing the same

a liquid crystal display and reflection type technology, applied in the direction of organic semiconductor devices, non-linear optics, instruments, etc., can solve the problems of high power dissipation, large volume, heavy weight,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, a reflection type liquid crystal display device and a method of manufacturing the reflection type liquid crystal display device according to the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

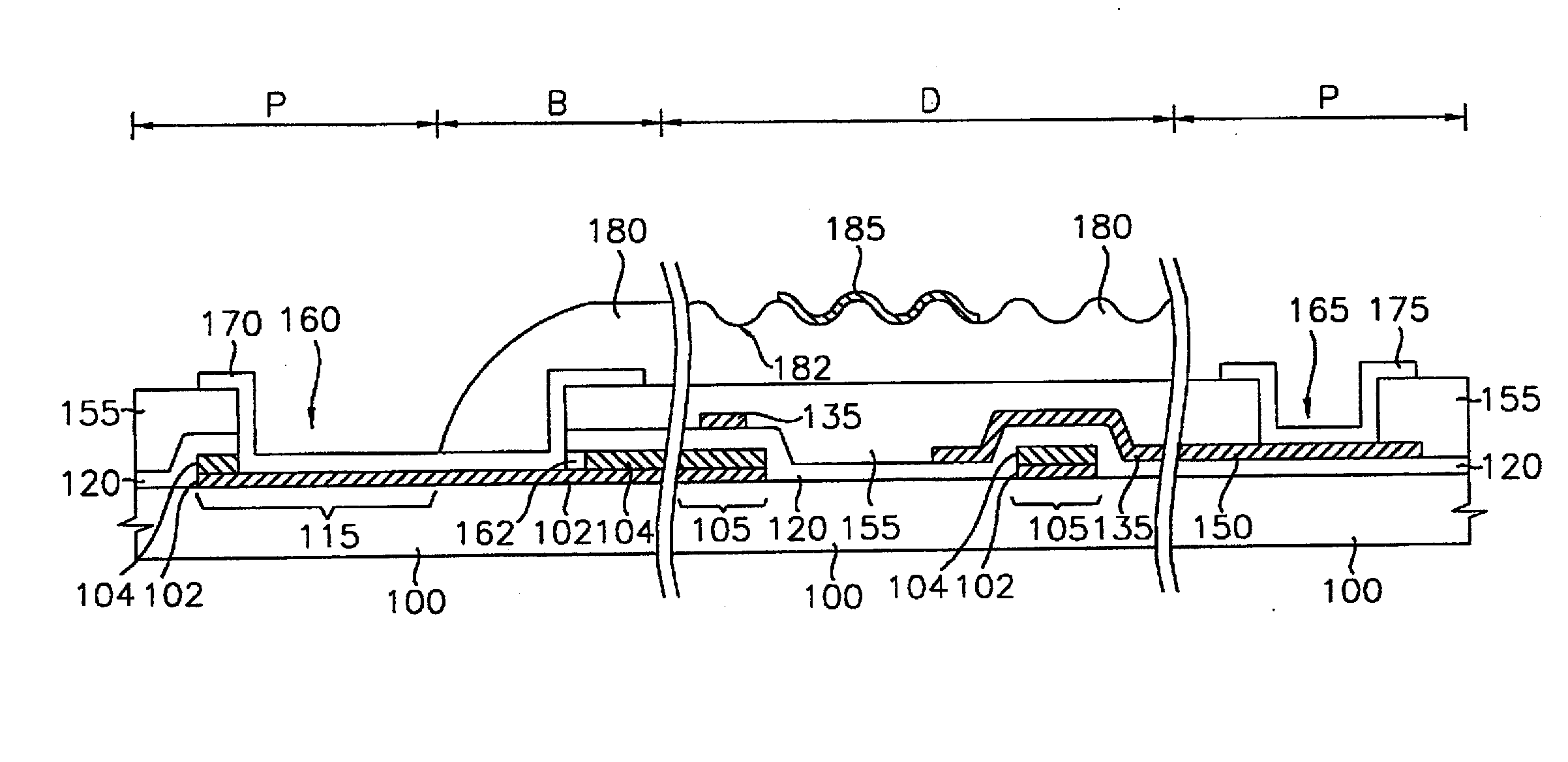

[0044]FIG. 3 is a plan view showing a reflection type liquid crystal display device according to the present invention. FIGS. 4A and 4B are cross-sectional views of the reflection type liquid crystal display device, taken along lines E-E′ and F-F′ in FIG. 3, respectively. The reflection type liquid crystal display device includes an amorphous silicon thin film transistor having a bottom-gate structure. Here, a reference symbol P shows a pad region; a reference symbol D indicated a display region; and a reference symbol B shows a boundary region located between the pad region and the display region. Here, the pad region P is formed outside the display region D so as to surround the display region D.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com