Method for Controlling Fluid Pressure in a Borehole Using a Dynamic Annular Pressure Control System

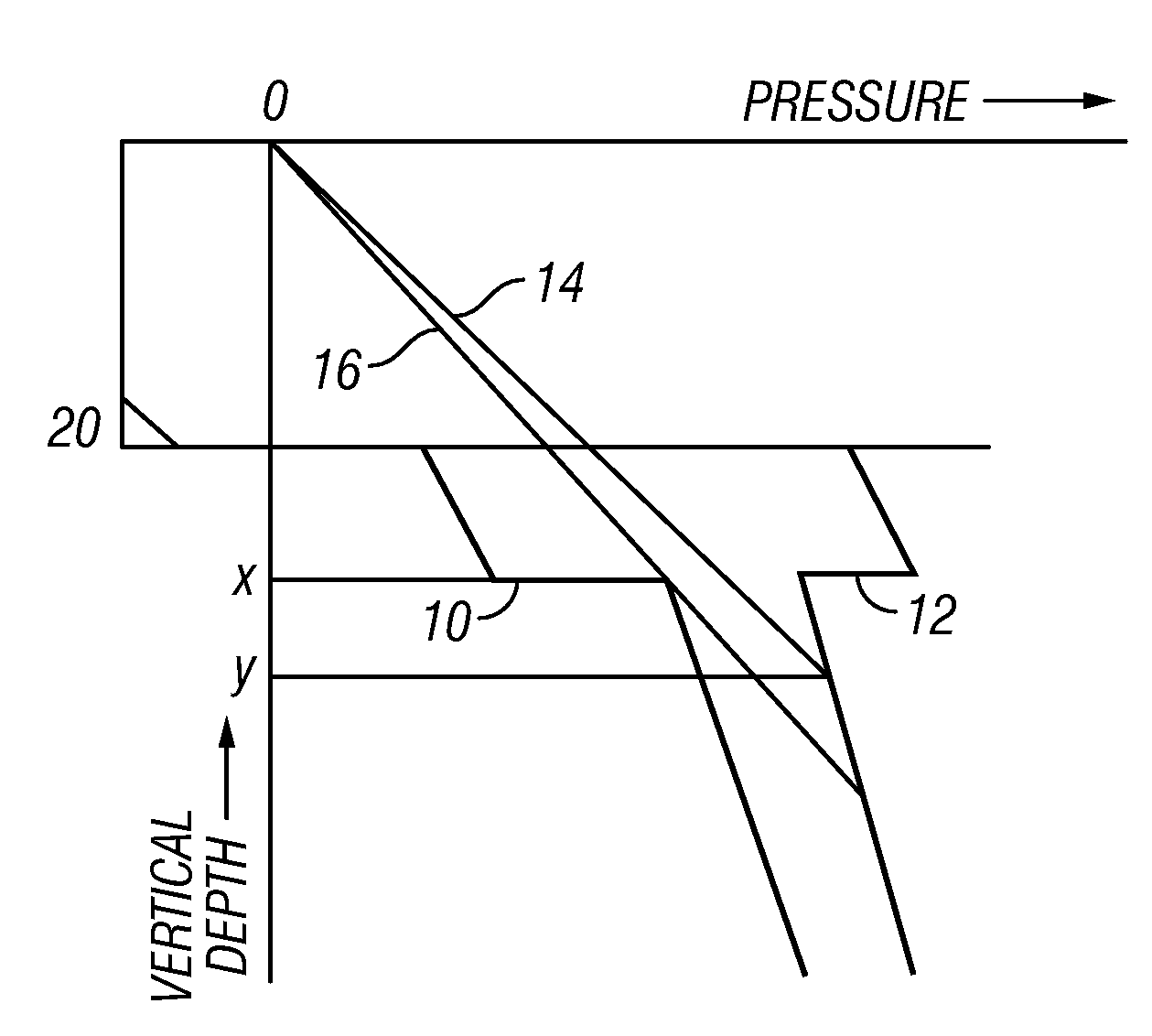

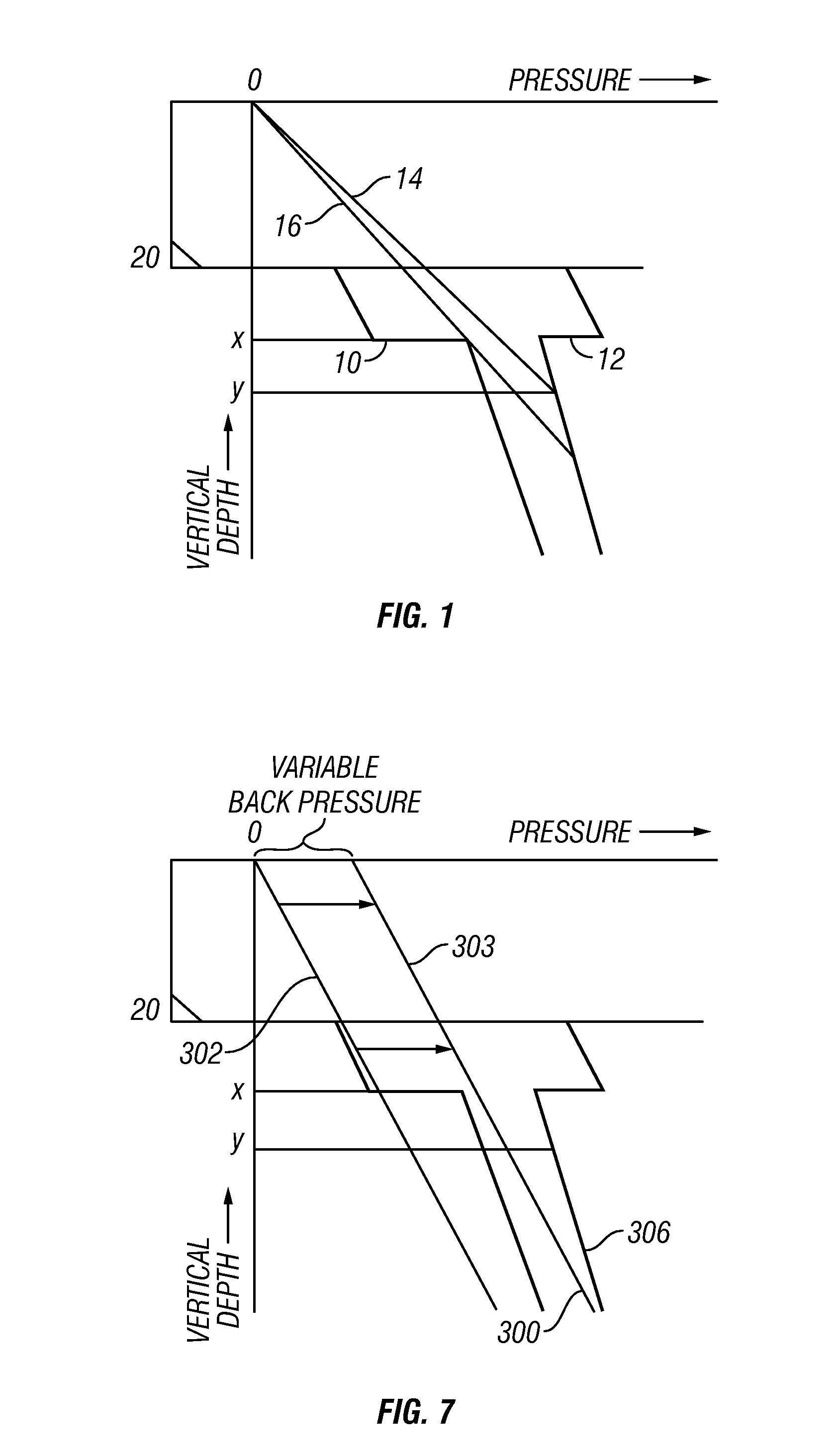

a control system and annular pressure technology, applied in earth drilling, well accessories, chemistry apparatus and processes, etc., can solve problems such as drilling fluid loss, fluid entering the formation pores, and creating fissures or fractures in the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

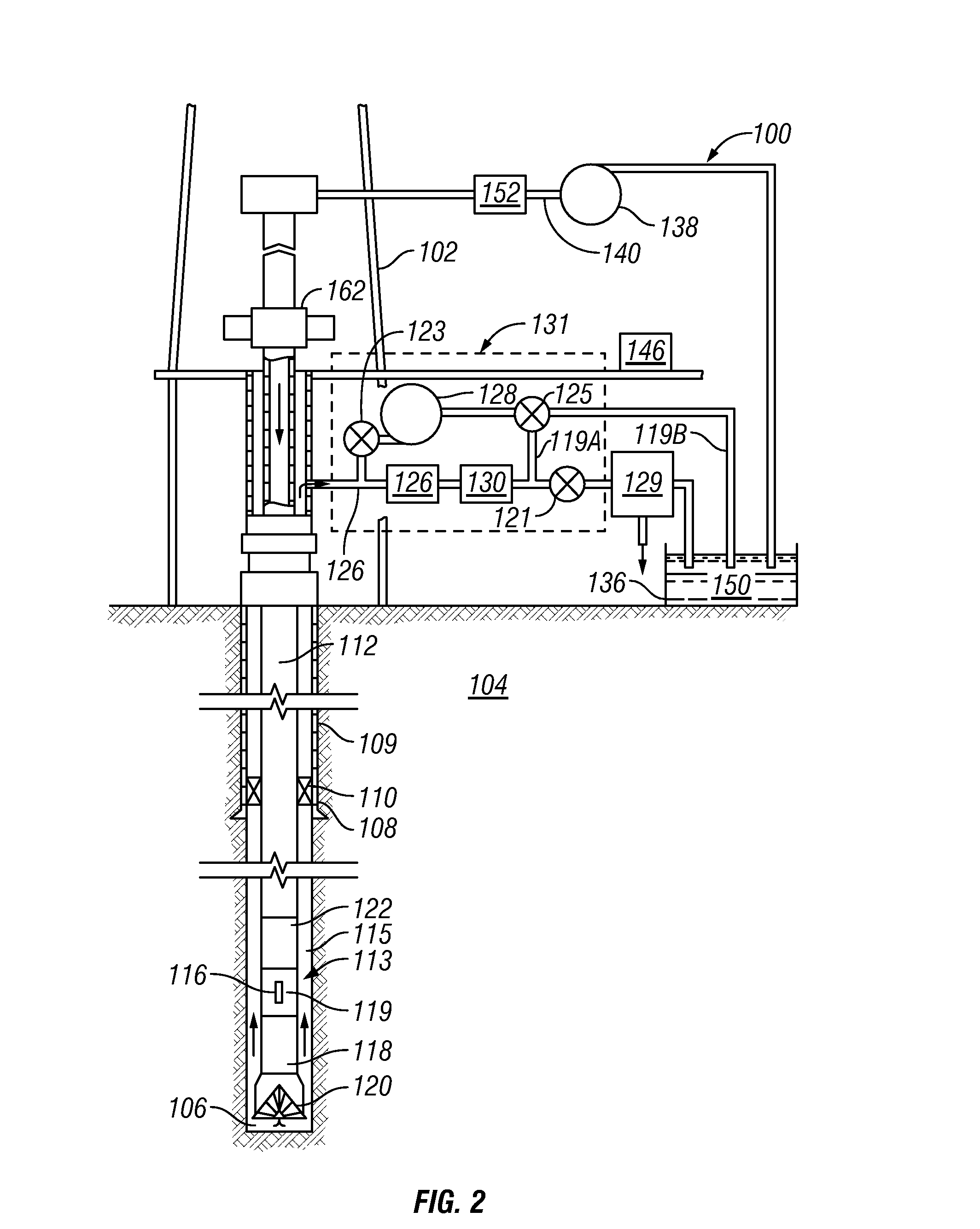

[0033]1. Drilling Circulation System and First Embodiment of a Backpressure Control System

[0034]FIG. 2A is a plan view depicting a land-based drilling system having one embodiment of a dynamic annular pressure control (DAPC) system that can be used with the invention. It will be appreciated that an offshore drilling system may likewise have a DAPC system using methods according to the invention. The drilling system 100 is shown including a drilling rig 102 that is used to support drilling operations. Many of the components used on the drilling rig 102, such as the kelly, power tongs, slips, draw works and other equipment are not shown separately in the Figures for clarity of the illustration. The rig 102 is used to support a drill string 112 used for drilling a borehole through Earth formations such as shown as formation 104. As shown in FIG. 2A the borehole 106 has already been partially drilled, and a protective pipe or casing 108 set and cemented 109 into place in part of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com