Fluid Bearing Device

a technology of bearings and fluids, which is applied in the direction of sliding contact bearings, bearing unit rigid supports, instruments, etc., can solve the problems of deterioration in the releasability of molded products at the time, and achieve the effects of high impact resistance, superior durability and reliability, and sufficient level of adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

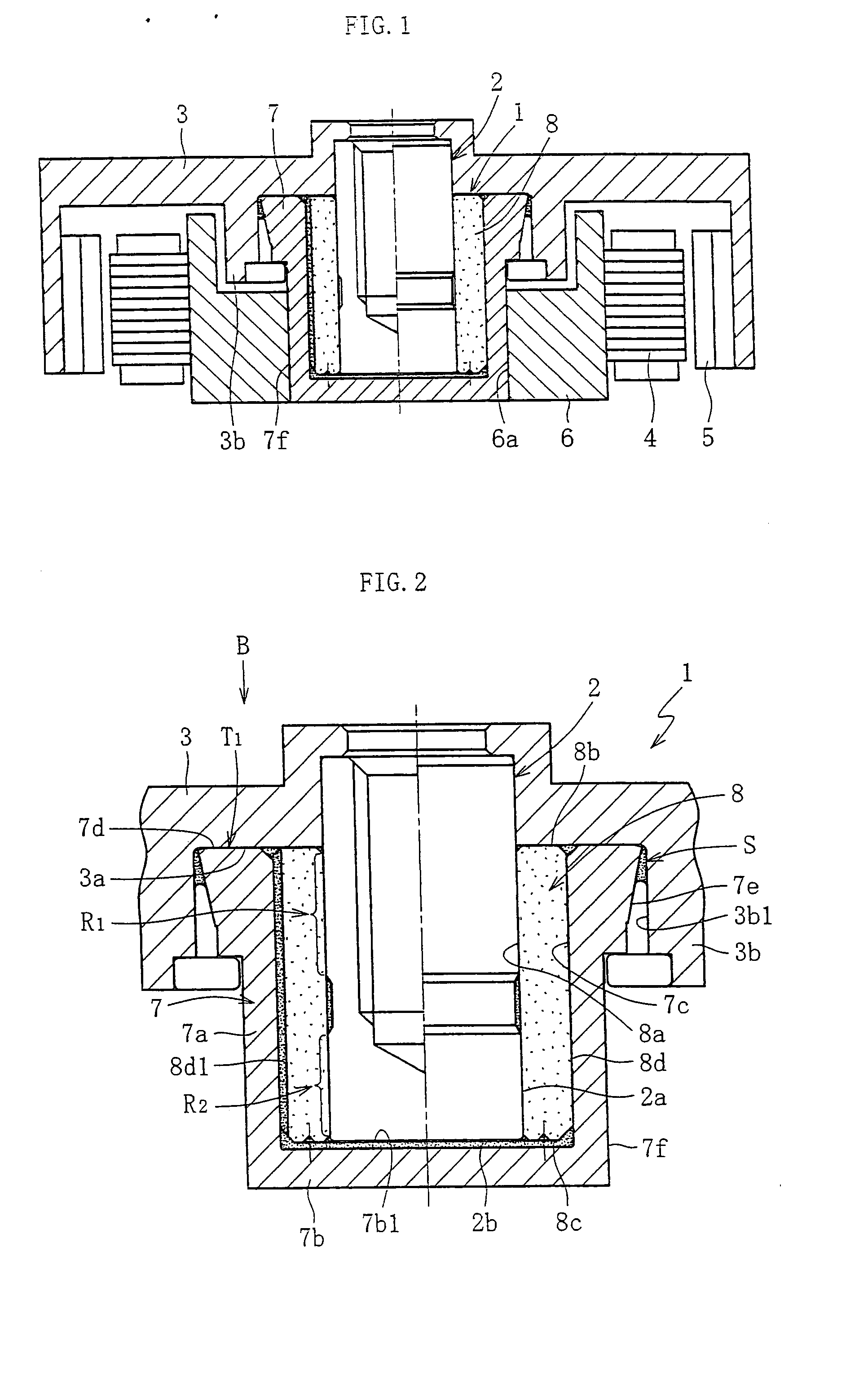

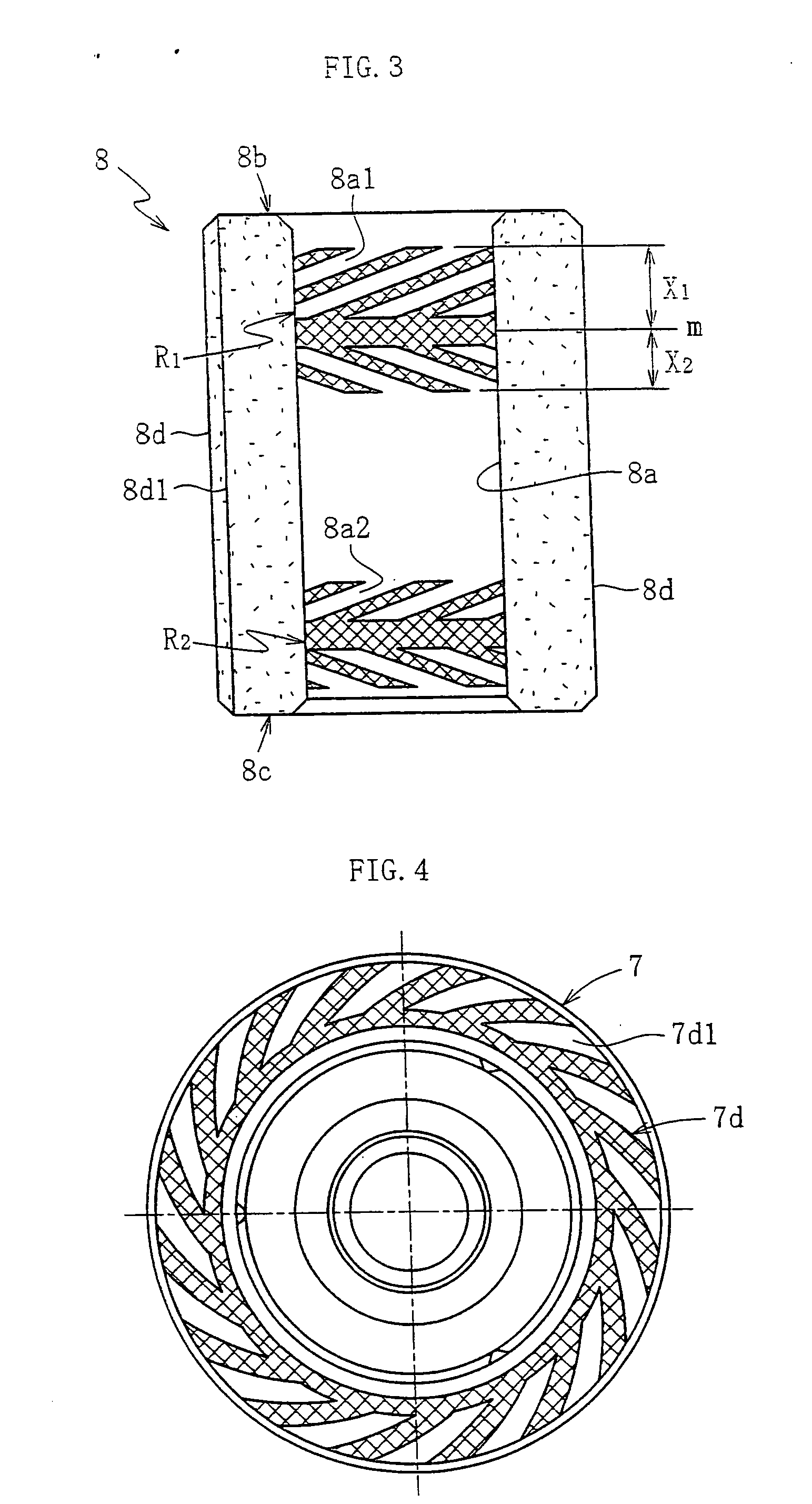

[0027] In the following, embodiments of the present invention will be described with reference to FIGS. 1 through 7.

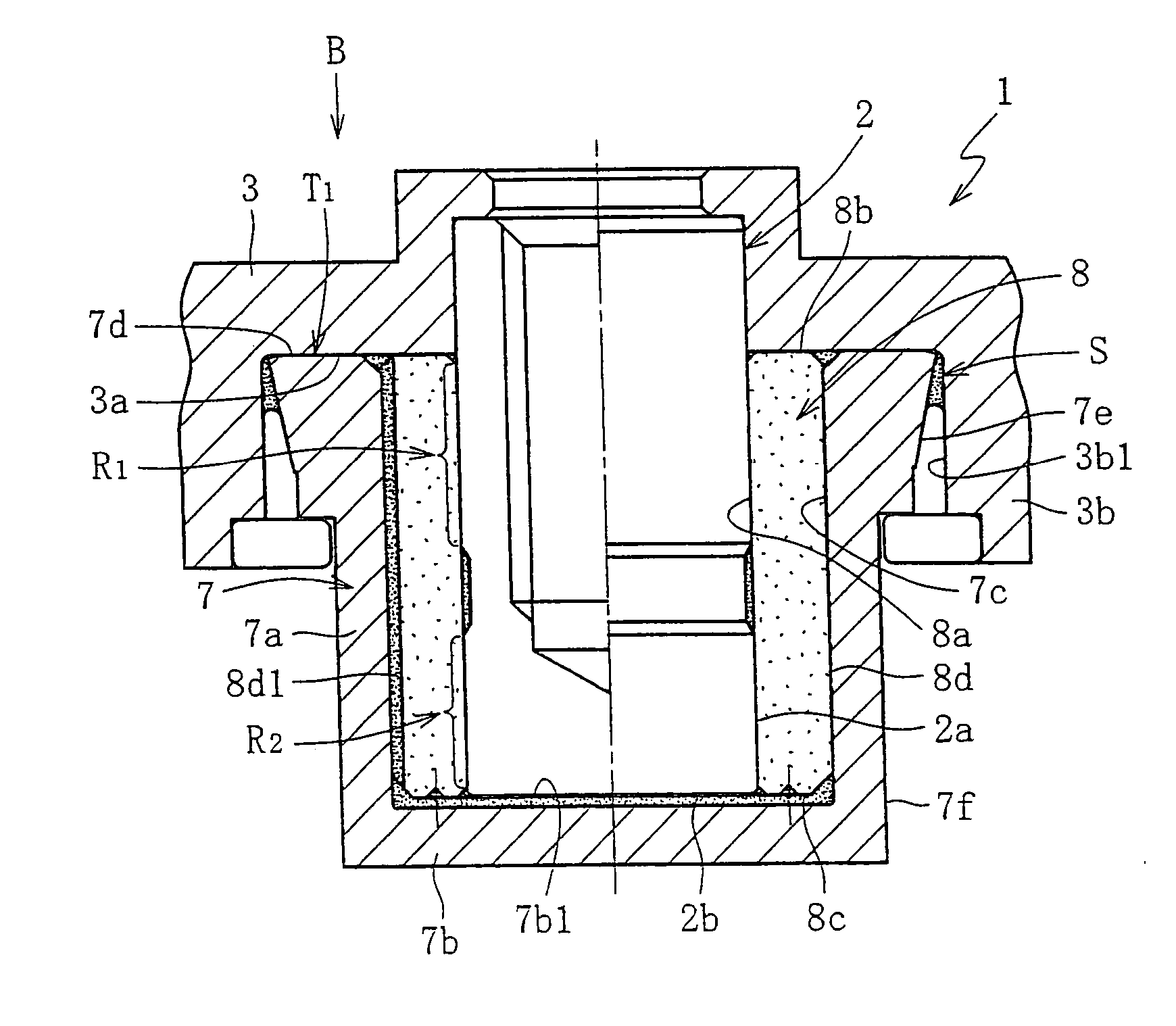

[0028]FIG. 1 conceptually shows an example of the construction of a spindle motor for an information apparatus with a dynamic pressure bearing device 1, supporting a shaft member 2 with a dynamic pressure oil film, incorporated therein. This spindle motor is used in a disc drive device, such as an HDD, and contains the dynamic pressure bearing device 1, a disc hub 3 mounted to a shaft member 2, and a stator coil 4 and a rotor magnet 5 that are opposed to each other through the intermediation, for example, of a radial gap. The stator coil 4 is mounted to the outer periphery of a bracket 6, and the rotor magnet 5 is mounted to the inner periphery of the disc hub 3. As described below, the dynamic pressure bearing 1 has a housing 7 fixed by adhesion to the inner periphery of the bracket 6. The disc hub 3 retains one or a plurality of discs D, such as magnetic discs (see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com