Exhaust Gas Control Apparatus for Internal Combustion Engine

a control apparatus and exhaust gas technology, applied in engine controllers, electric control, machines/engines, etc., can solve the problems of insufficient increase of exhaust gas temperature by downstream oxidation catalysts, ineffective oxidation of particulate matter, and excessive space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following description, the present invention will be described in more detail in terms of exemplary embodiments.

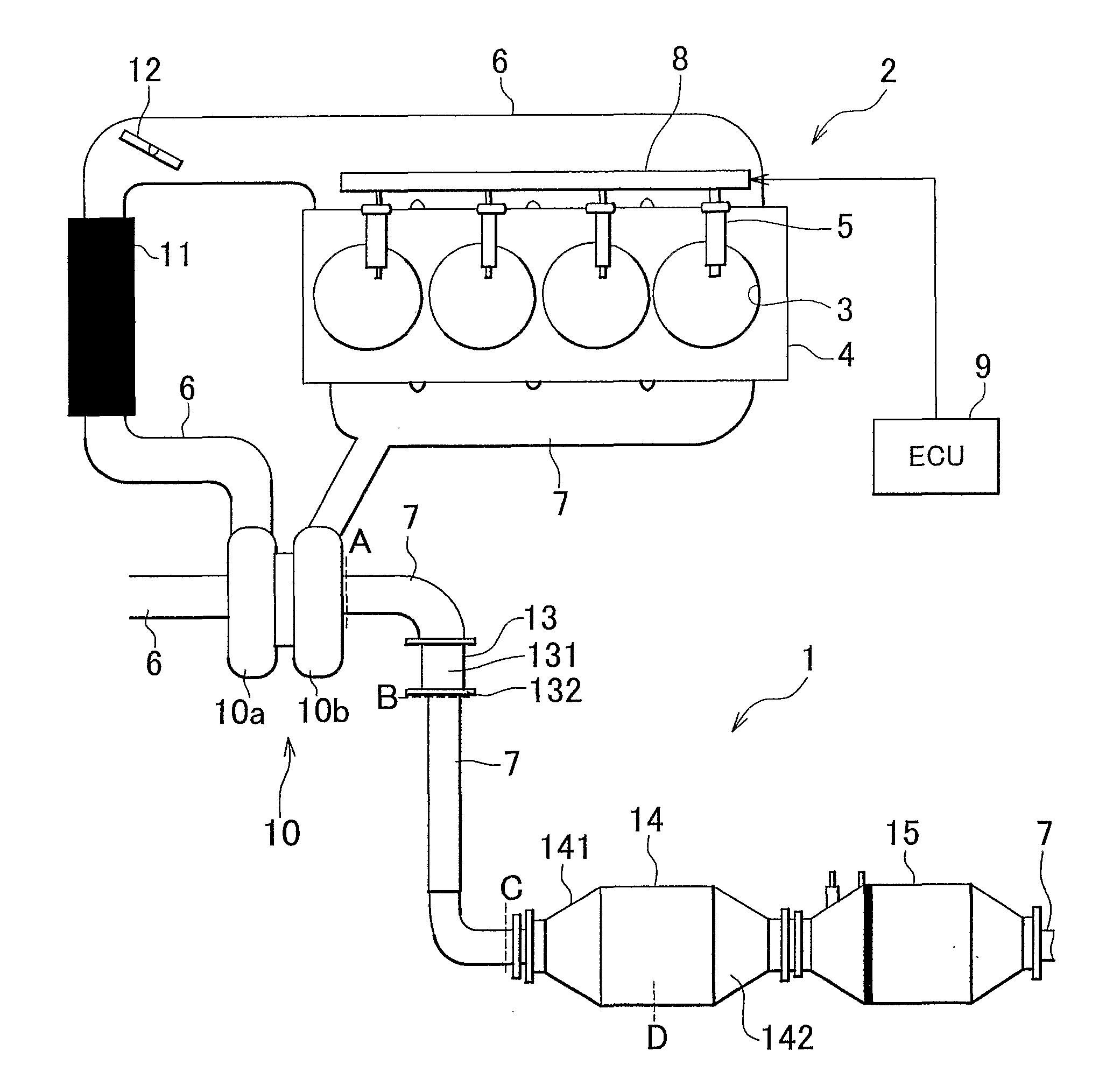

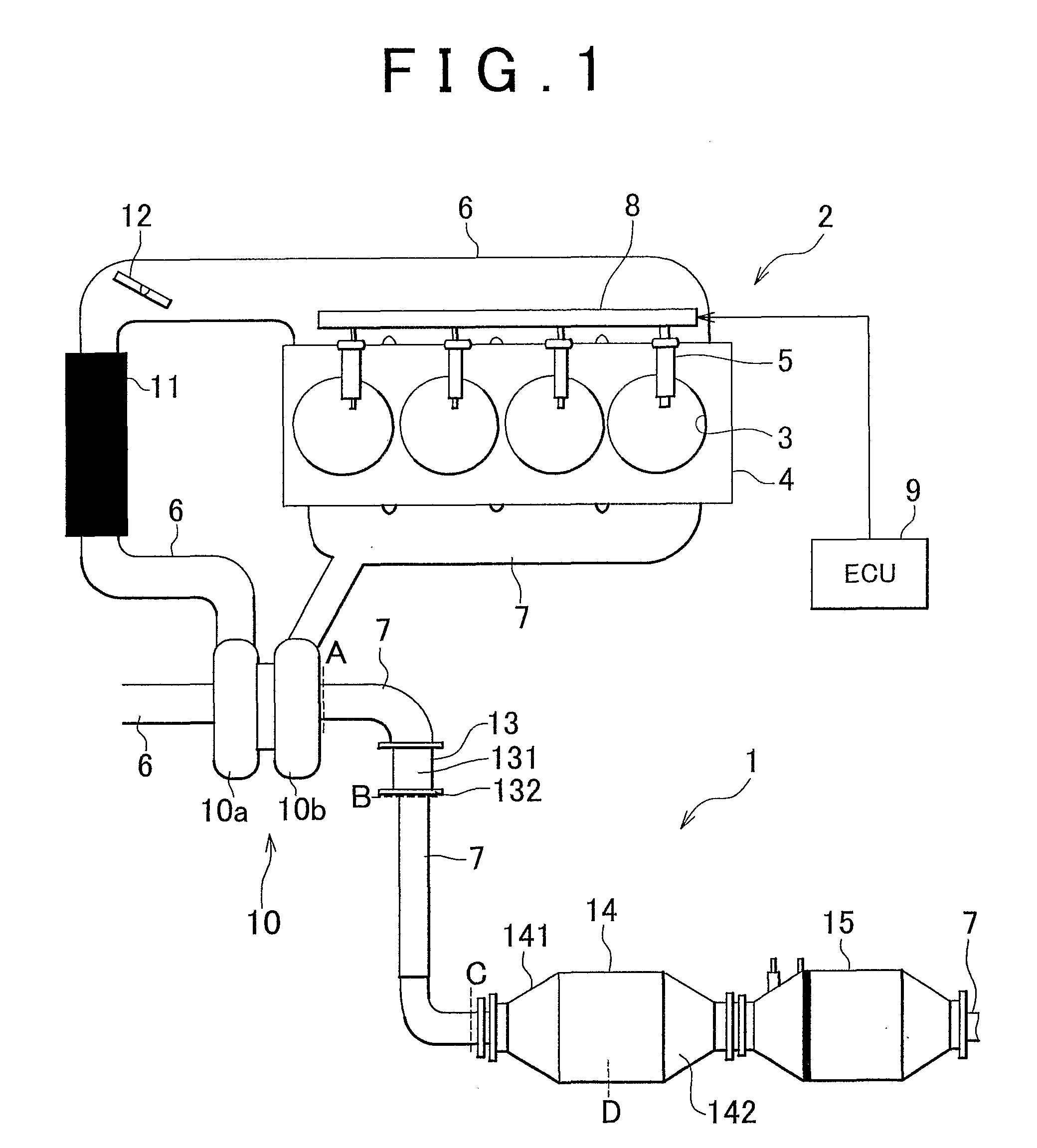

[0019]FIG. 1 is a view schematically showing a diesel engine (hereinafter, simply referred to as an “engine”) 2 to which an exhaust gas control apparatus 1 according to the invention is applied. As shown in FIG. 1, the engine 2 is a reciprocating four-cylinder engine. The engine 2 includes a cylinder block 4 in which cylinders 3 are formed, injectors 5 which are provided for the respective cylinders 3, and an intake passage 6 and an exhaust passage 7 which are connected to the cylinder block 4. The injectors 5 are connected to a common rail 8, and inject fuel, which has been supplied to the common rail 8 under pressure by a pressure pump (not shown) and then stored in the common rail 8, to the respective cylinders 3. An engine control unit (ECU) 9 controls an amount of fuel injected by the injectors 5, fuel injection timing, and the like.

[0020] A compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com