Programmable semiconductor device

a technology of programmable semiconductors and semiconductors, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device details, instruments, etc., can solve the problems of fuse pitch, post-collateral damage of neighboring structures, and known semiconductor e-fuses that have not been completely satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

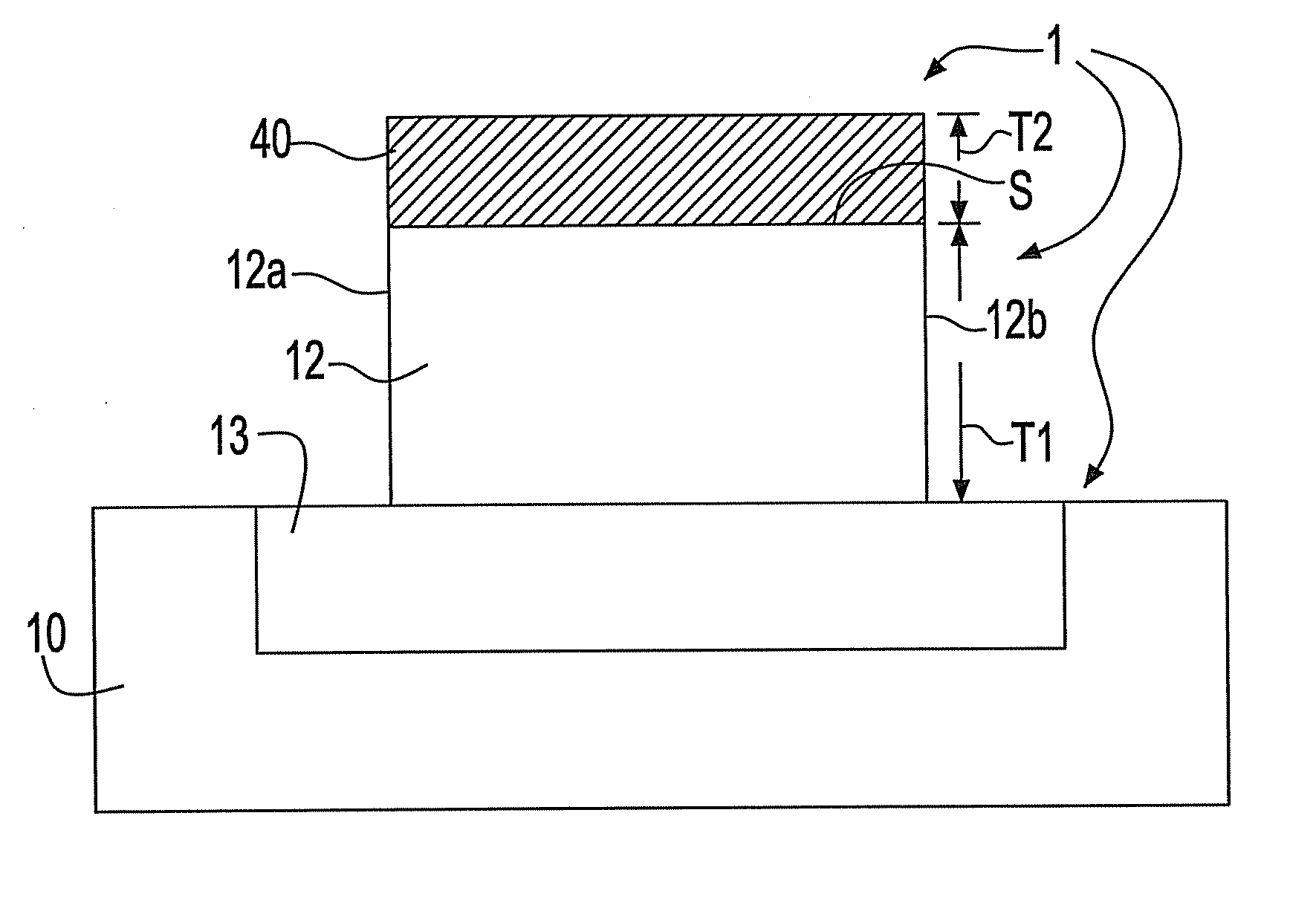

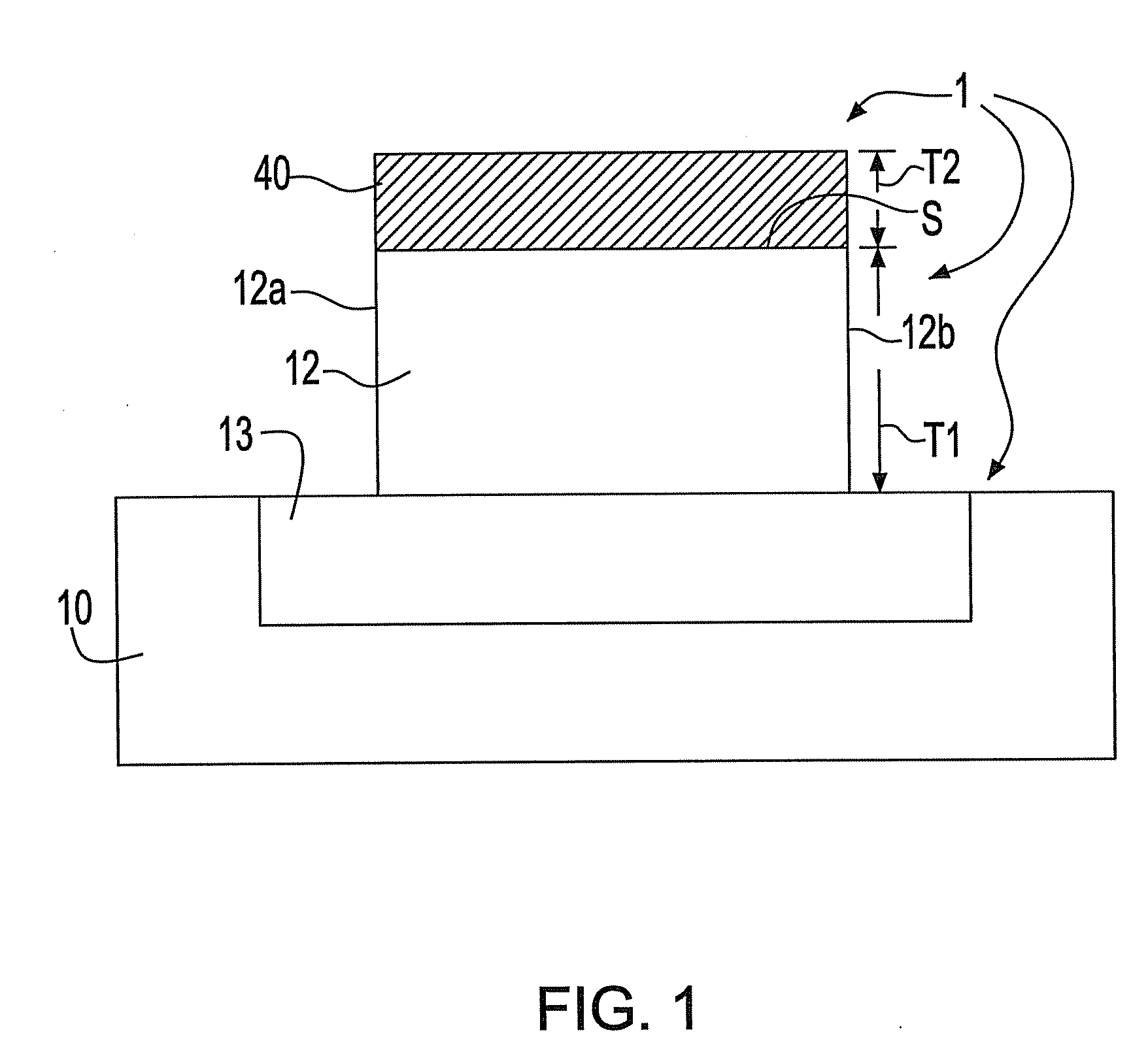

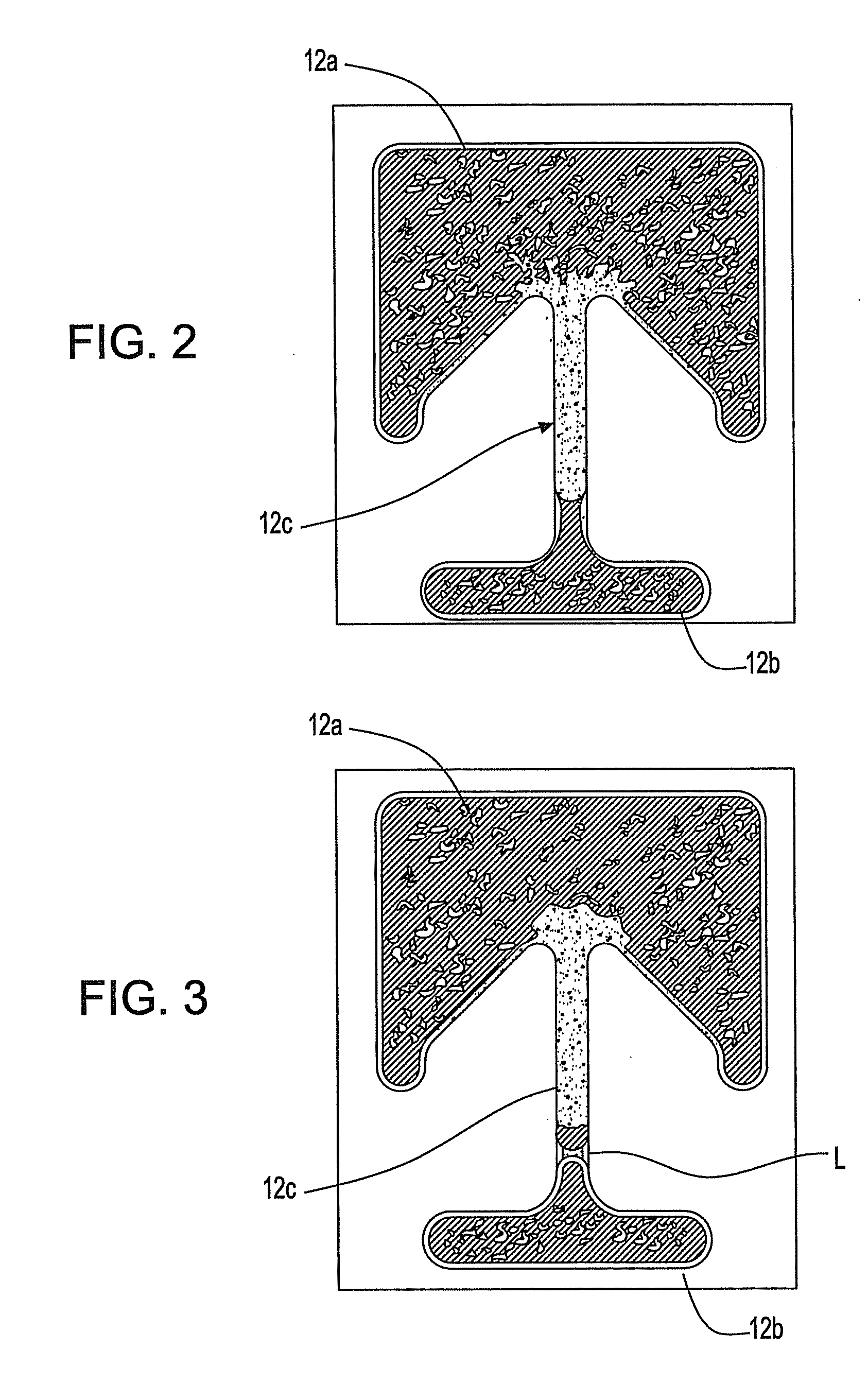

[0022]FIG. 1 shows a preferred programmable (un-programmed) semiconductor device (1) (e.g. fuse) in cross section. The fuse (1) includes an elongated semiconductor material (12) having a metallic material (40) disposed on an upper surface S. The material (12) is disposed on / over an isolation region (13) in a silicon substrate (10). Preferably, the unprogrammed fuse includes N+ polysilicon (90 nm height / thickness T1) (12) and WSi2 (55 nm height / thickness T2) (40). The region (13) is, for example, filled with an insulator such as an oxide. The region (13) is, for example, a known shallow trench isolation (STI) region. The device (1) includes a first end (12a), a second end (12b) and a central portion or link (12c) connecting the first end (12a) to the second end (12b). Preferably, the link (12c) and the second end (12b), together, form a “T”-shaped member (FIG. 2, and FIGS. 11a, 11b).

[0023] According to an important feature of the present invention, the resistivity of the metallic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com