Non-halogen flame-resistant thermoplastic elastomer composition, manufacturing method thereof, and electric wire or cable in which its elastomer composition is used

a thermoplastic elastomer and composition technology, applied in the direction of fireproof paints, etc., can solve the problems of difficult to set the color hue of the molding freely, limit the softness of the composition to a halogen system material such as polyvinyl chloride, and emit nasty smells. achieve the effect of the same softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

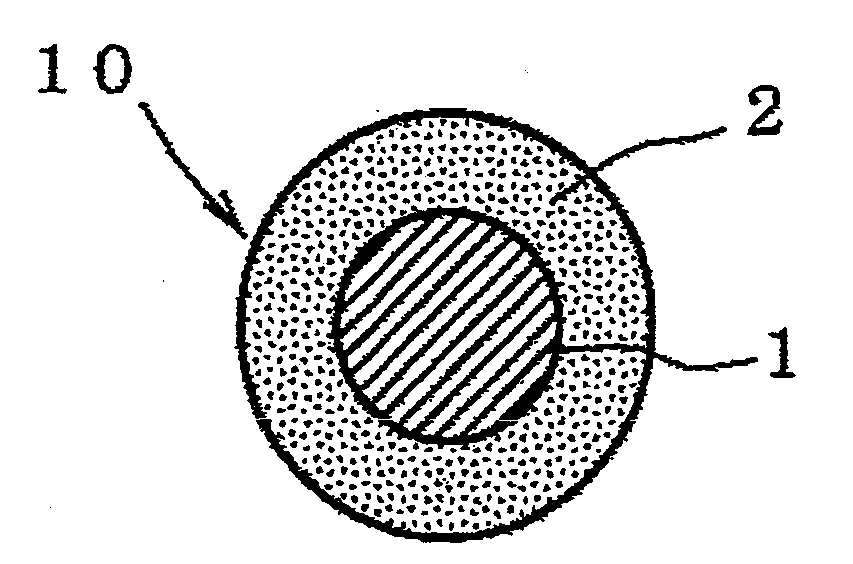

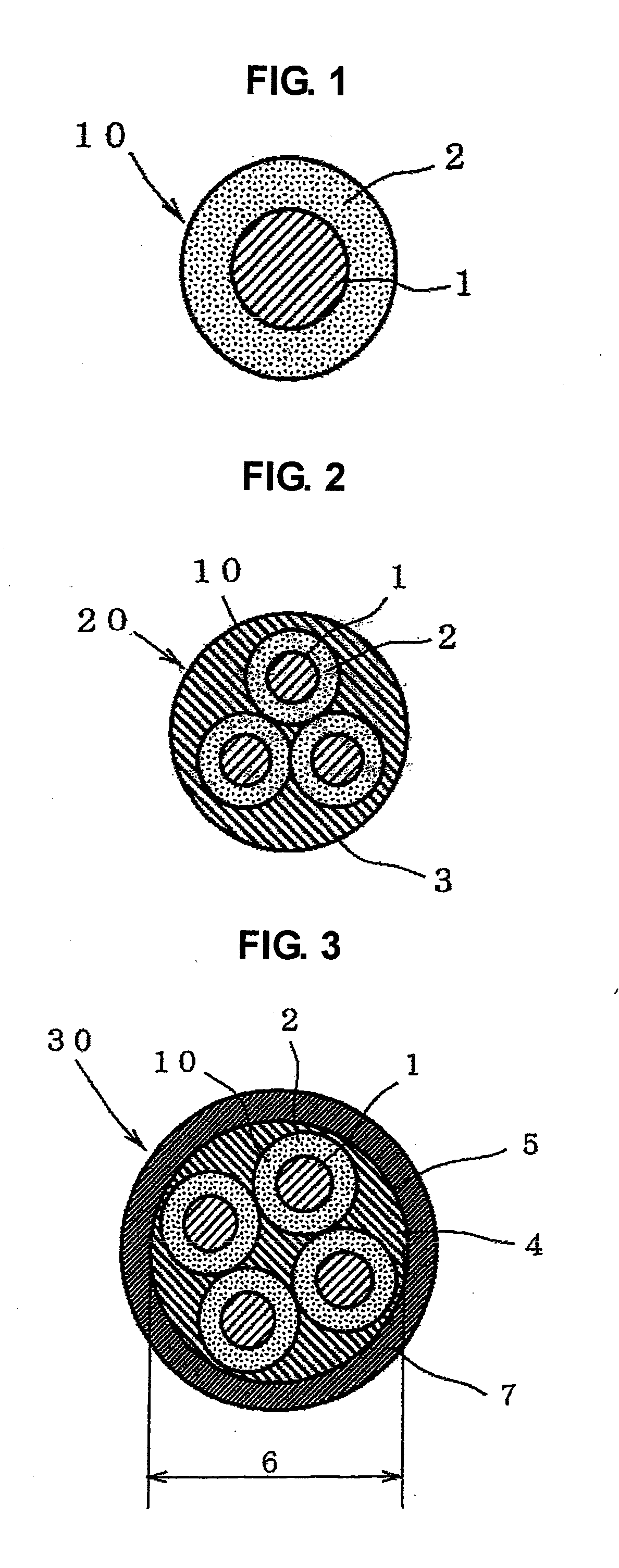

Image

Examples

embodiments

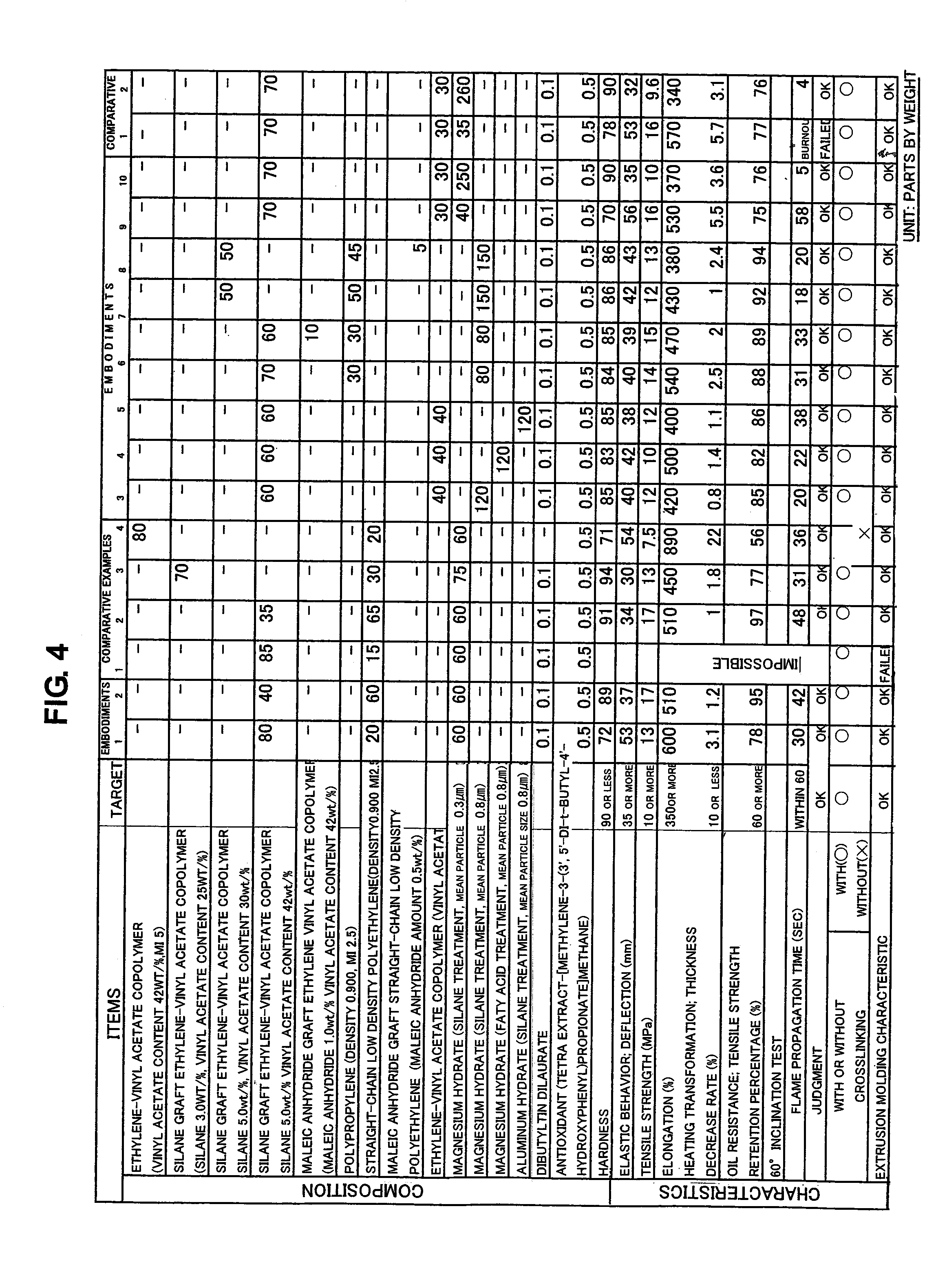

[0073]Embodiments of the present invention will be concretely explained hereinafter.

[0074]The material was made according to a process where silicon analogues are graft-copolymerized to ethylene vinyl acetate copolymer, and a process where compounding ingredients such as ethylene vinyl acetate copolymers in which silicon analogues are graft-copolymerized, crystalline polyolefin resins, metalhydroxides, and silanol condensation catalysts are mixed to cross-link ethylene vinyl acetate copolymer by silane.

[0075]In the process where silicon analogues are graft-copolymerized to ethylene vinyl acetate copolymer, raw materials where ethylene vinyl acetate copolymers (the content of vinyl acetate is 25, 30, and 42 wt %), vinyl trimethoxysilanes, and dicumylperoxides are impregnated and mixed at the ratio of 100 / 3 / 0.01 parts by weight or 100 / 5 / 0.02 parts by weight are prepared. These were extruded so that retention time may become about five minutes by using 40 mm extruder at 200° C. (L / D ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com