Flooded evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

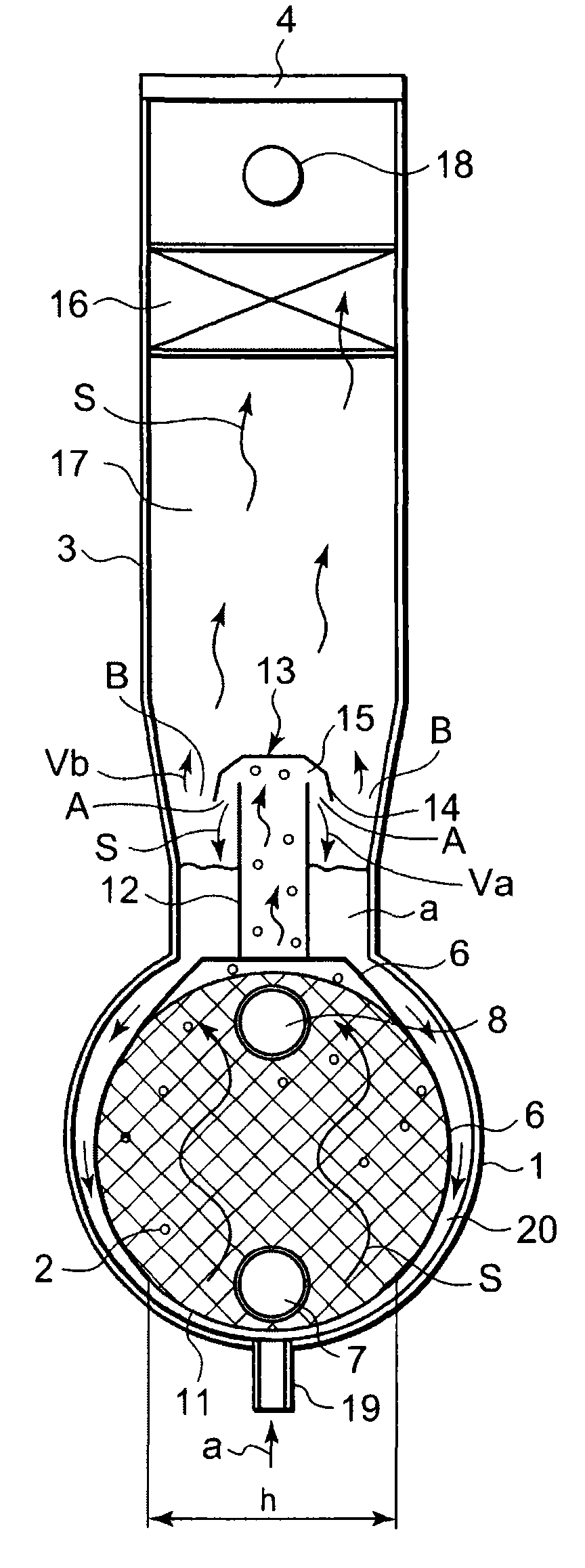

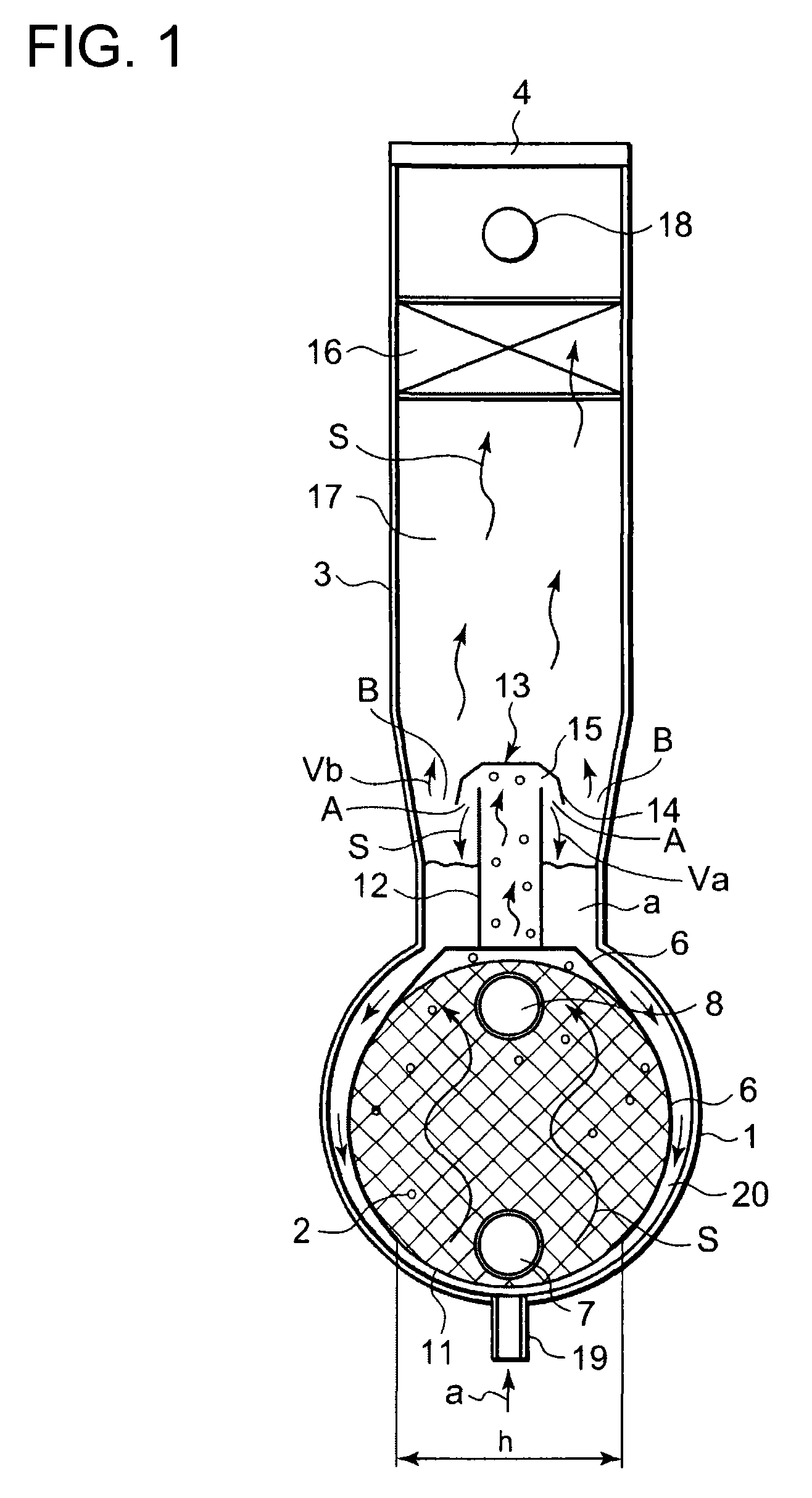

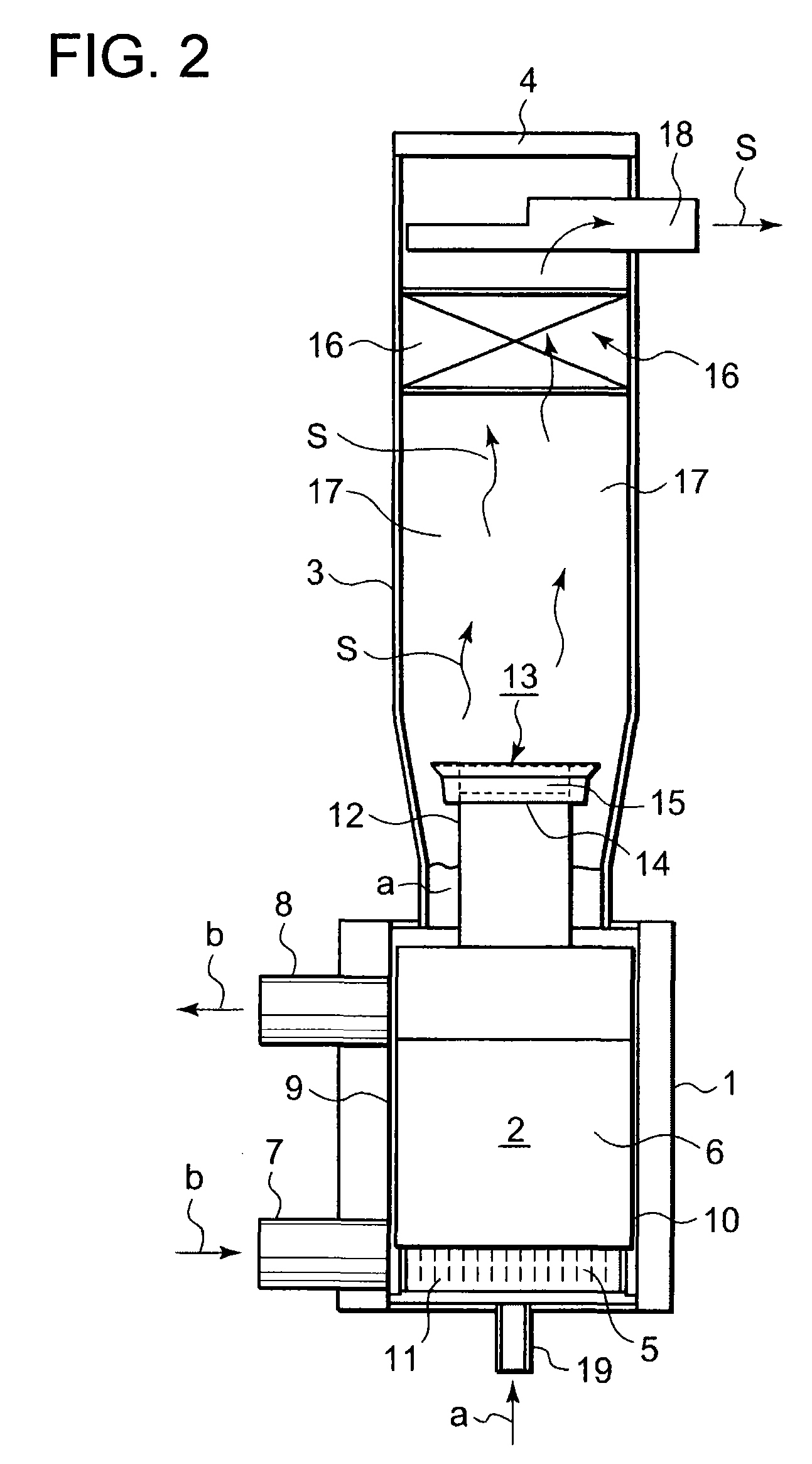

[0065] Referring to FIGS. 1-3, reference numeral 1 is a horizontal cylindrical container in which a heat exchanger 2 is accommodated. Reference numeral 3 is a tubular housing extending upward from the cylindrical container 1 which composes a refrigerant mist separating section. The tubular housing 3 is closed at the top thereof by a cover 4.

[0066] The heat transfer plates 5 are arranged parallel to each other at certain spacing and the upper part of the heat exchanger 2 including the upper part of the heat transfer plates 5 is covered with a cover plate 6. Reference numeral 7 is an inlet pipe for introducing a medium to be cooled ‘b’ and reference numeral 8 is an outlet pipe through which the medium cooled in the heat exchanger 2 flows out from the heat exchanger 2. The inlet pipe 7 and outlet pipe 8 are connected with heat exchanging tubes (not shown in the drawings, intersections of crosshatched lines indicating centers of the heat exchanging tubes) arranged i...

second embodiment

The Second Embodiment

[0080] Next, a second embodiment of the invention will be explained with reference to FIGS. 5-7. The second embodiment is an example of a case the flooded evaporator of the invention is applied to an ammonia refrigerating machine. In FIGS. 5-7, constituents the same as those of FIGS. 1-3 are indicated by the same reference numerals and symbols. Reference numerals 7 and 8 in FIGS. 5-7 are inlet pipes and outlet pipes for introducing and letting out the medium to be cooled and cooled medium into and from the heat exchanger 2 respectively. Unlike the first embodiment, in the second embodiment the inlet pipes 7 and outlet pipes 8 are provided at both ends of the horizontal cylindrical container 1 respectively. The outlet pipe 18 is connected to the upper part of each of two tubular housings 3 so that refrigerant vapor from each of the tubular housings 3 flows together therethrough. Reference numeral 21 is a support member for supporting the supply pipe 19 for introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com