Electromagnetic fuel pump

a fuel pump and electromagnetic technology, applied in the direction of pump components, positive displacement liquid engines, pump parts, etc., can solve the problems of increasing the cost of electromagnetic fuel pumps, achieve excellent fuel delivery efficiency, avoid chip generation, and reduce a number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The description will be given below of a best mode for carrying out the present invention with reference to the accompanying drawings.

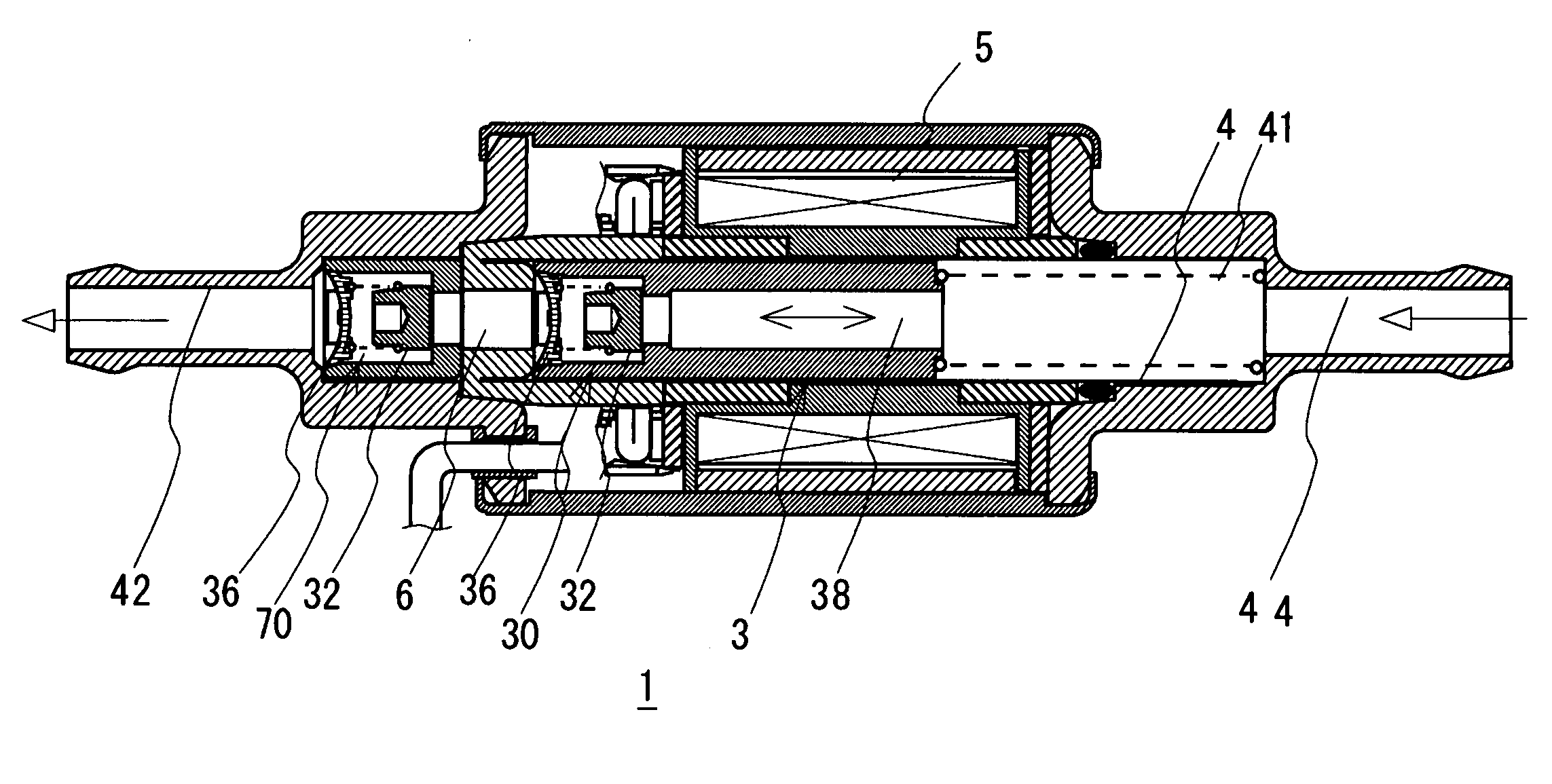

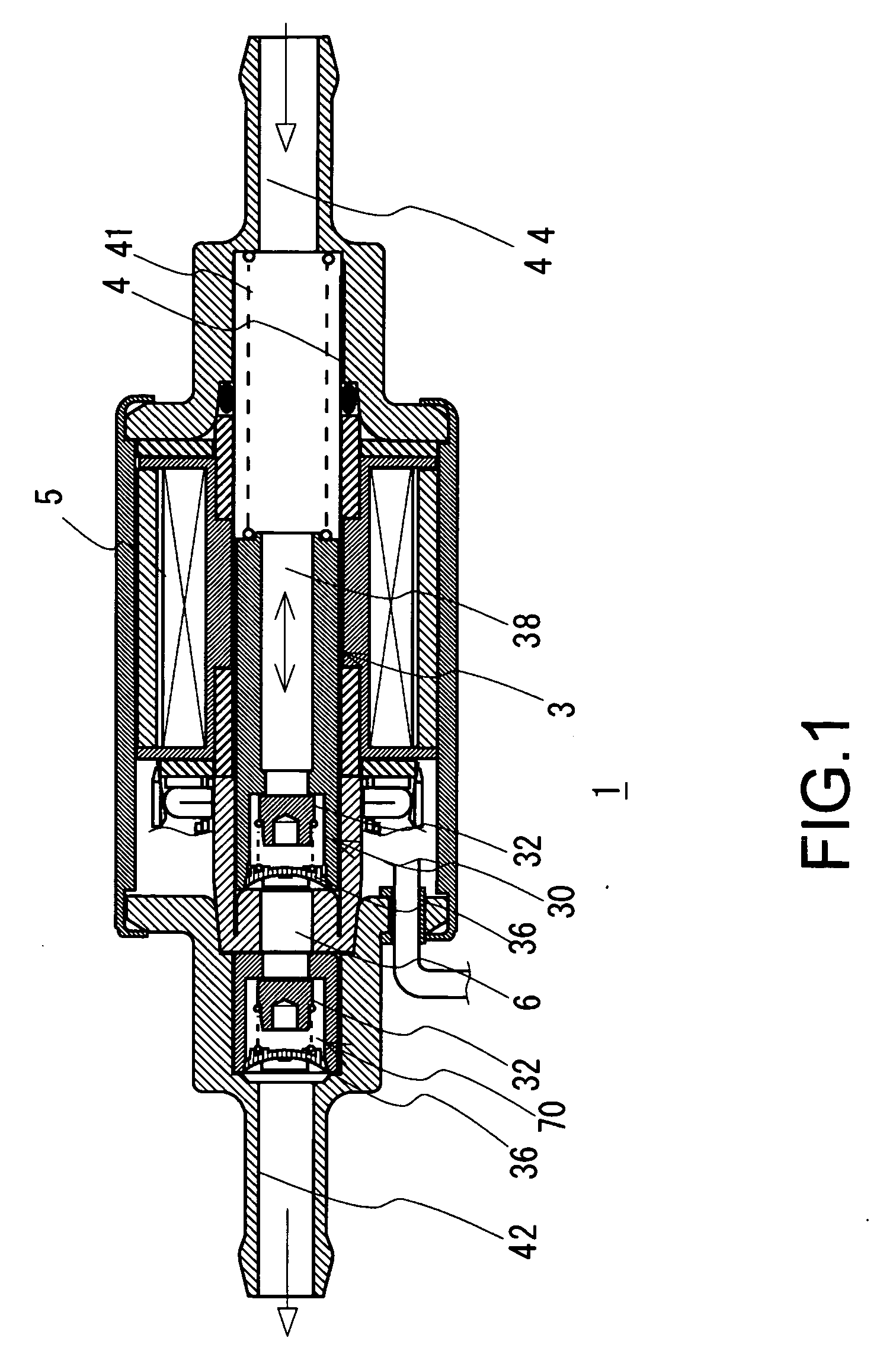

[0023]FIG. 1 shows a longitudinal cross sectional view of an electromagnetic fuel pump 1, for example, in the case that the present invention is used in a fuel supply system of a gasoline engine. The electromagnetic fuel pump 1 delivers a fuel corresponding to a gasoline reserved in a fuel tank (not shown) so as to supply it to an engine via a fuel piping by an injector, and is called as a so-called cylinder type electromagnetic fuel pump.

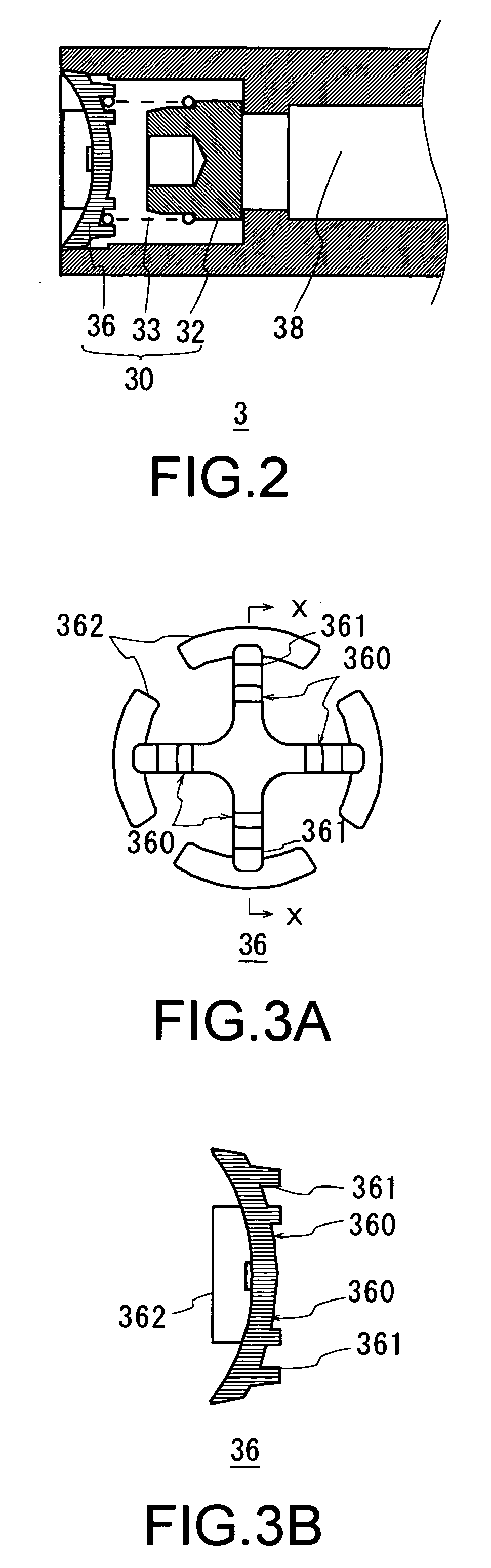

[0024]The electromagnetic fuel pump 1 is structured such that an electromagnetic coil 5 is provided around a cylinder 4, and a plunger 3 is slidably arranged in the cylinder 4 so as to be slidable in a horizontal direction in the drawing. A return spring 41 is arranged on a rear end side of the plunger 3 in a compressed state, and urges the plunger 3 toward the downward side, i.e., toward the left in the drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com