Refrigeration System

a refrigeration system and expansion chamber technology, applied in the field of refrigeration systems, can solve the problems of reducing the power extracted from the expansion chamber, deteriorating the coefficient of performance (cop) of the refrigeration system, etc., and achieve the effect of preventing deterioration in cop, reducing cooling capacity, and reducing cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

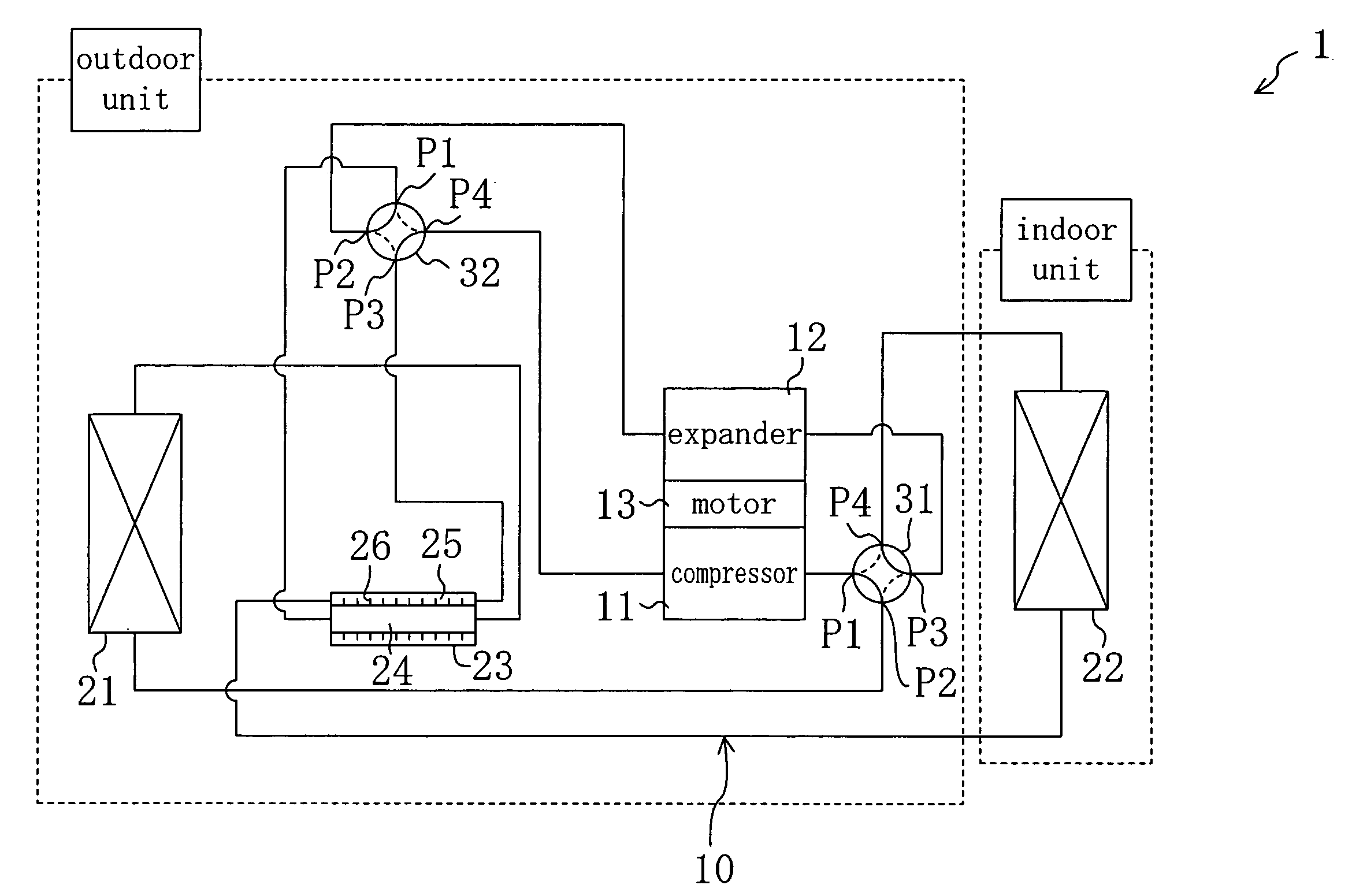

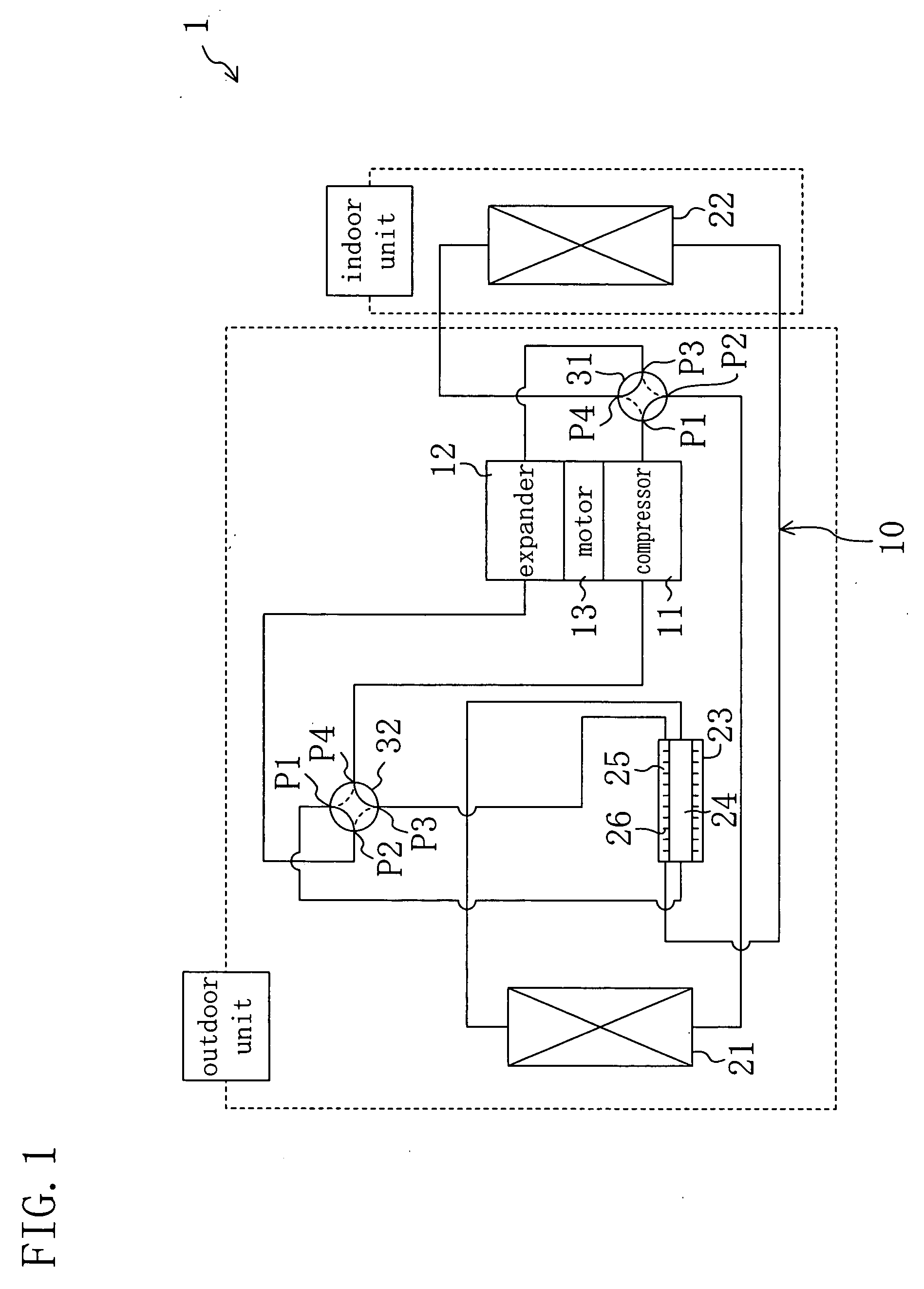

embodiment 1

Effects of Embodiment 1

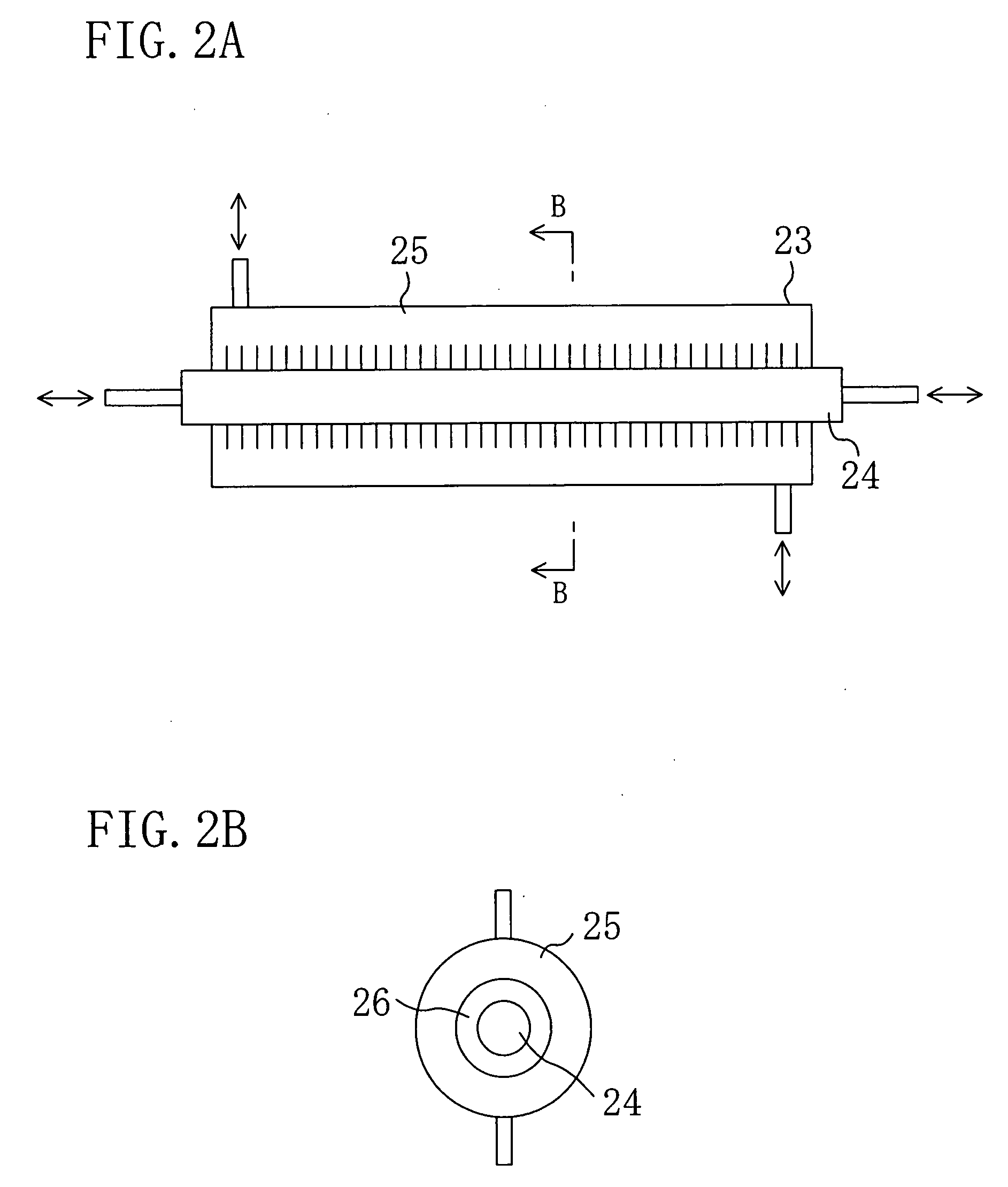

[0214] According to Embodiment 1, in the internal heat exchanger (23) during the cooling operation, refrigerant after passing through the indoor heat exchanger (22) serving as an evaporator flows through the outer channel (25) and refrigerant after passing through 20 the outdoor heat exchanger (21) serving as a gas cooler flows through the inner channel (24). On the other hand, in the internal heat exchanger (23) during the heating operation, refrigerant after passing through the indoor heat exchanger (22) serving as a gas cooler flows through the outer channel (25) and refrigerant after passing through the outdoor heat exchanger (21) serving as an evaporator flows through the inner channel (24). In addition, the outer channel (25) is provided with heat transfer fins (26).

[0215] Thus, during the cooling operation, gas refrigerant after passing through the evaporator flows through the outer channel (25), whereby refrigerant in the inner channel (24) comparativ...

embodiment 2

Effects of Embodiment 2

[0227] Also in Embodiment 2, during the cooling operation, gas refrigerant after passing through the indoor heat exchanger (22) serving as an evaporator flows through the outer channel (25). Therefore, refrigerant in the inner channel (24) comparatively efficiently exchanges heat with refrigerant in the outer channel (25) and the supercritical refrigerant decreases its temperature to reduce its specific volume and then flows in this state into the expander (12). On the other hand, during the heating operation, gas refrigerant after passing through the outdoor heat exchanger (21) serving as an evaporator flows through the inner channel (24). Therefore, refrigerant in the outer channel (25) hardly exchanges heat with refrigerant in the inner channel (24) and the supercritical refrigerant flows into the expander (12) substantially without changing its temperature.

[0228] Since, as described above, the specific volume and flow rate of refrigerant flowing into the ...

embodiment 3

Effects of Embodiment 3

[0240] Also in Embodiment 3, during the cooling operation, gas refrigerant after passing through the indoor heat exchanger (22) serving as an evaporator flows through the outer channel (25). Therefore, refrigerant in the inner channel (24) comparatively efficiently exchanges heat with refrigerant in the outer channel (25) and the supercritical refrigerant decreases its temperature to reduce its specific volume and then flows in this state into the expander (12). On the other hand, during the heating operation, gas refrigerant after passing through the outdoor heat exchanger (21) serving as an evaporator flows through the inner channel (24). Therefore, refrigerant in the outer channel (25) hardly exchanges heat with refrigerant in the inner channel (24) and the supercritical refrigerant flows into the expander (12) substantially without changing its temperature.

[0241] Since, as described above, the specific volume and flow rate of refrigerant flowing into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com