Noise-attenuating laminate composite wallboard panel and methods for manufacturing same

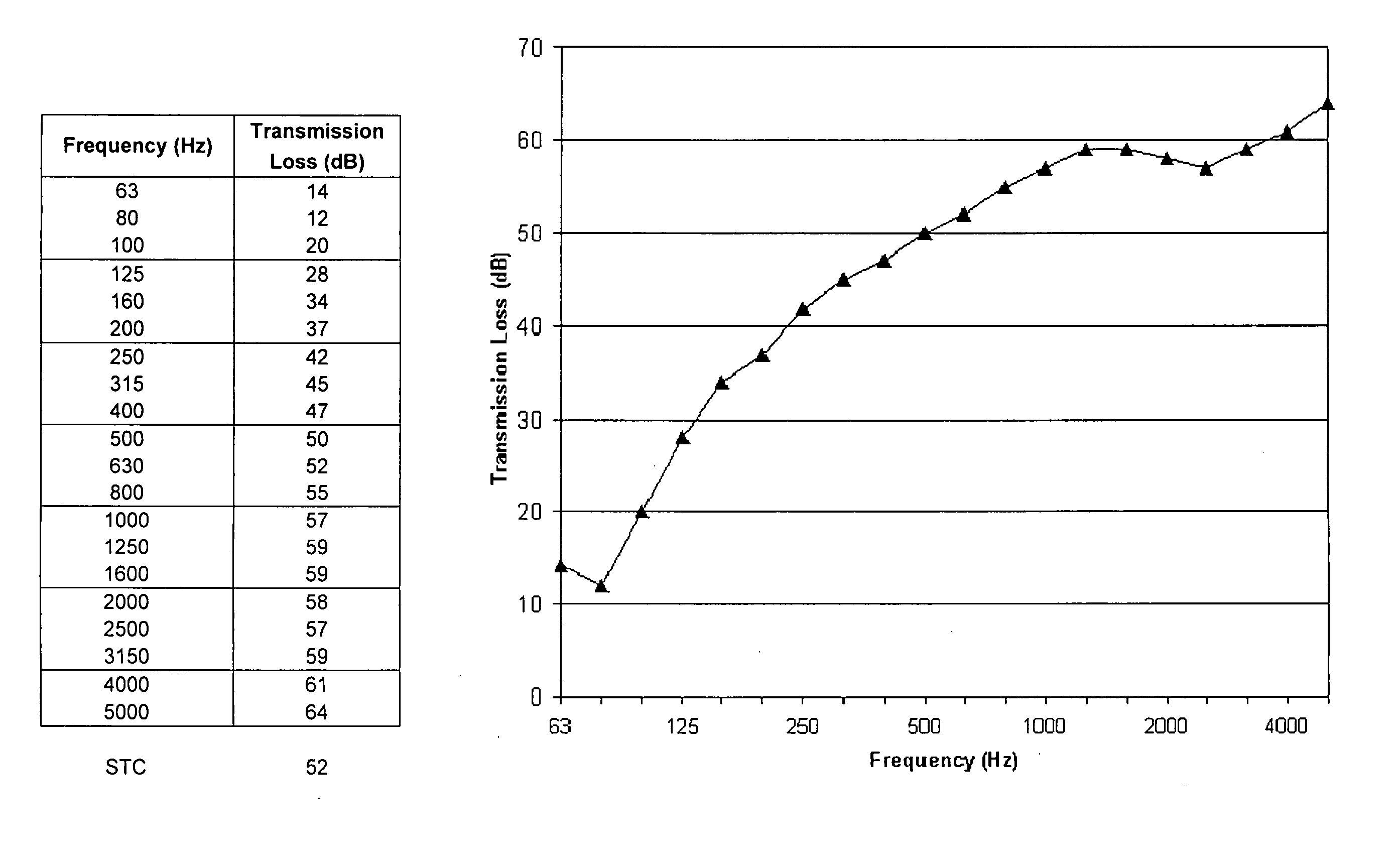

a laminate composite wallboard and noise-attenuating technology, applied in the field of building materials, can solve the problems of using surface and section together without uniformity, and achieve the effects of superior noise attenuation, superior noise attenuation, and similar weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following description is intended to be exemplary only and not to in any way limit the scope or objective of the invention. The preferred embodiments referred to below describe a laminate composite wallboard system. This invention, however, is not limited to wallboards, but can be used in any application where a noise-attenuating building material is desired.

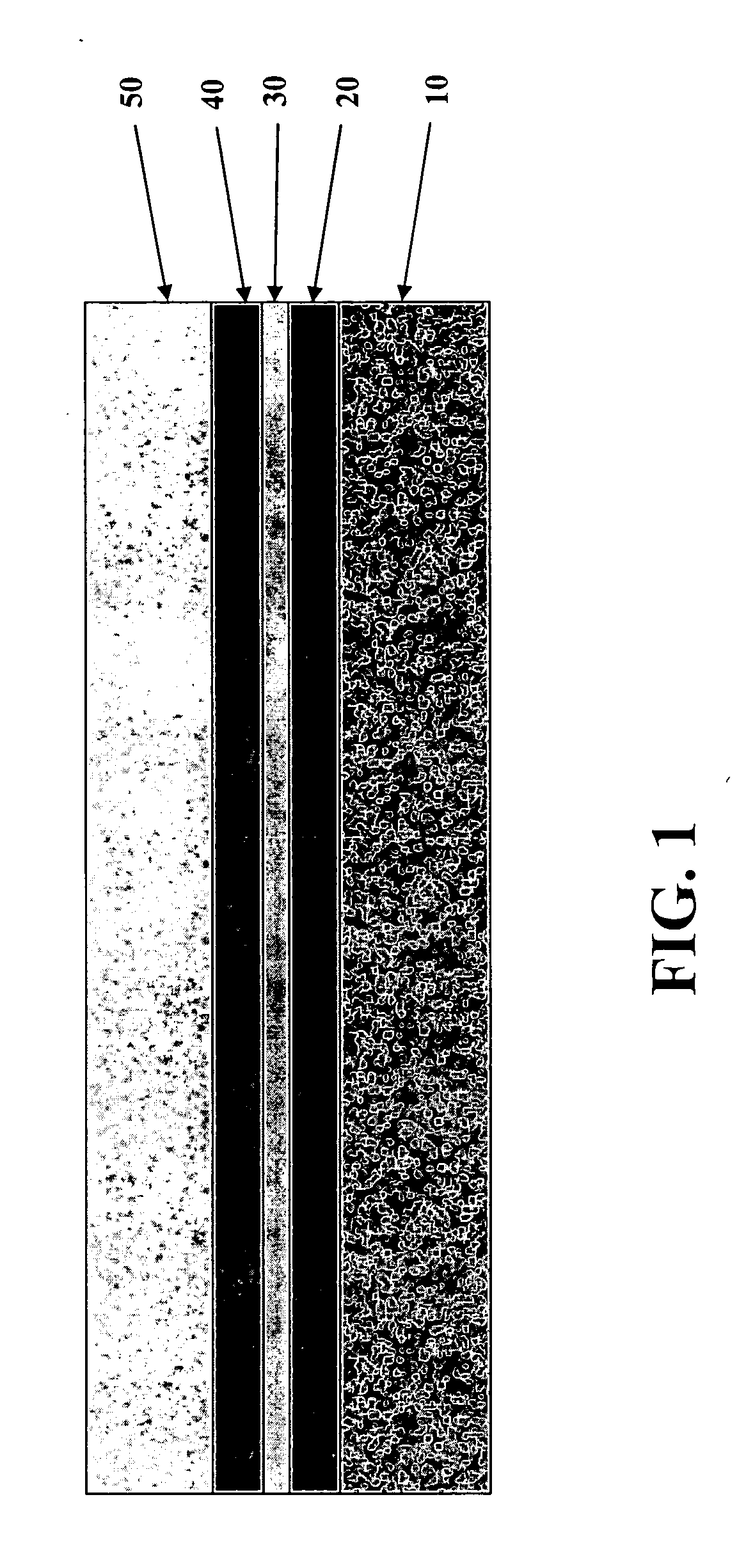

[0035]FIG. 1 shows a cross-section of a preferred embodiment of a wallboard panel constructed with the present invention, which wallboard panel is a five-layer laminate consisting of a standard gypsum panel 10 whose non-facing side is adjacent to a layer of viscoelastic adhesive 20. On the side of the viscoelastic adhesive 20 away from the gypsum panel 10 is a layer of absorbent paper 30. Then, on the side of the absorbent paper 30 away from the viscoelastic adhesive 20 is another layer of viscoelastic adhesive 40. Then, on the side of viscoelastic adhesive 40 away from the absorbent paper 30 is an MgO panel 50.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com