Scale removal system

a technology of scale removal and system, applied in specific water treatment objectives, electrolysis components, water/sewage treatment by electrochemical methods, etc., can solve the problems of scale components such as silica, magnesium and calcium included in for-treatment water as scales, deterioration of wettability of elements, and remarkable shortening of element life, so as to achieve the effect of avoiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

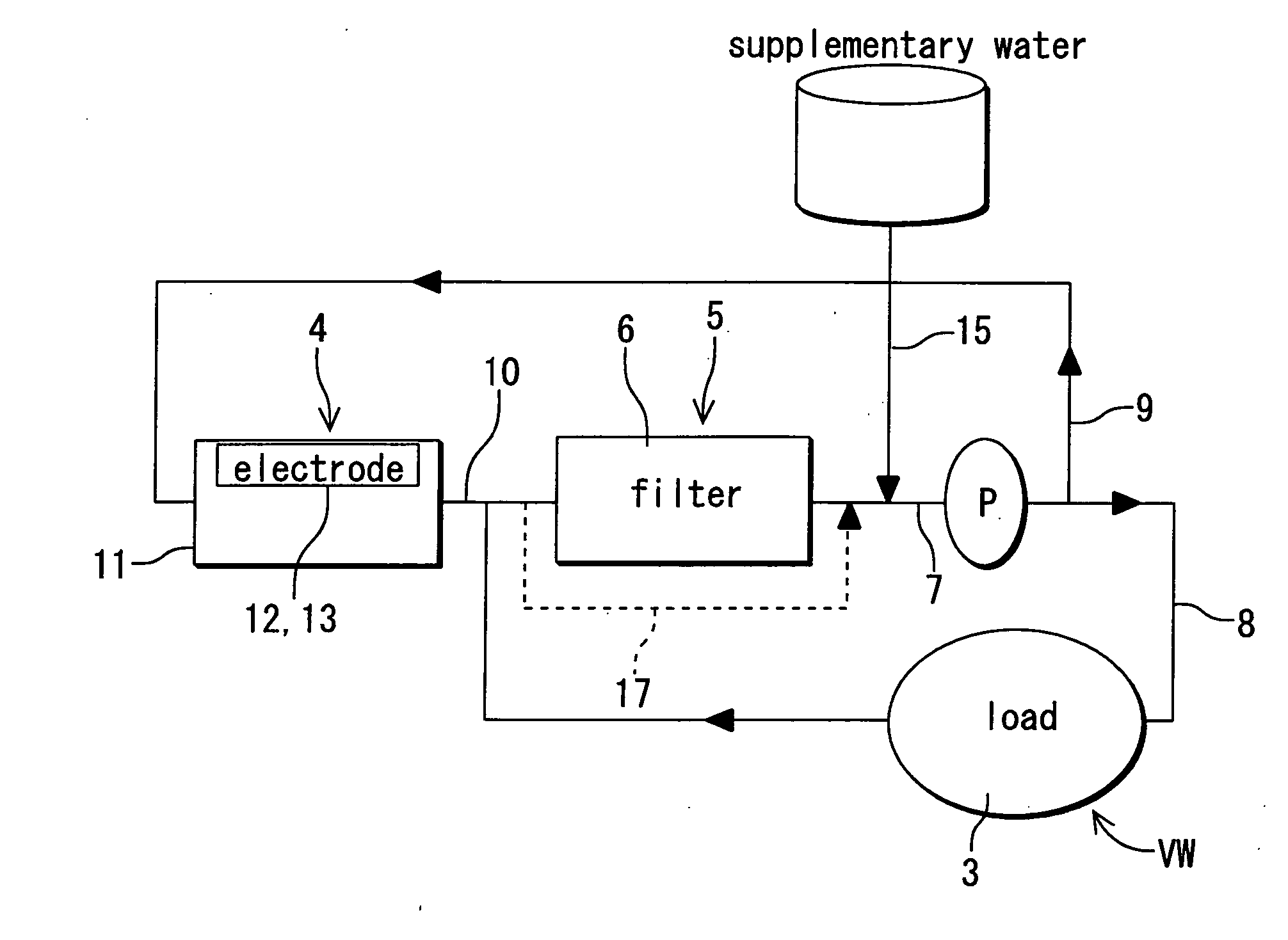

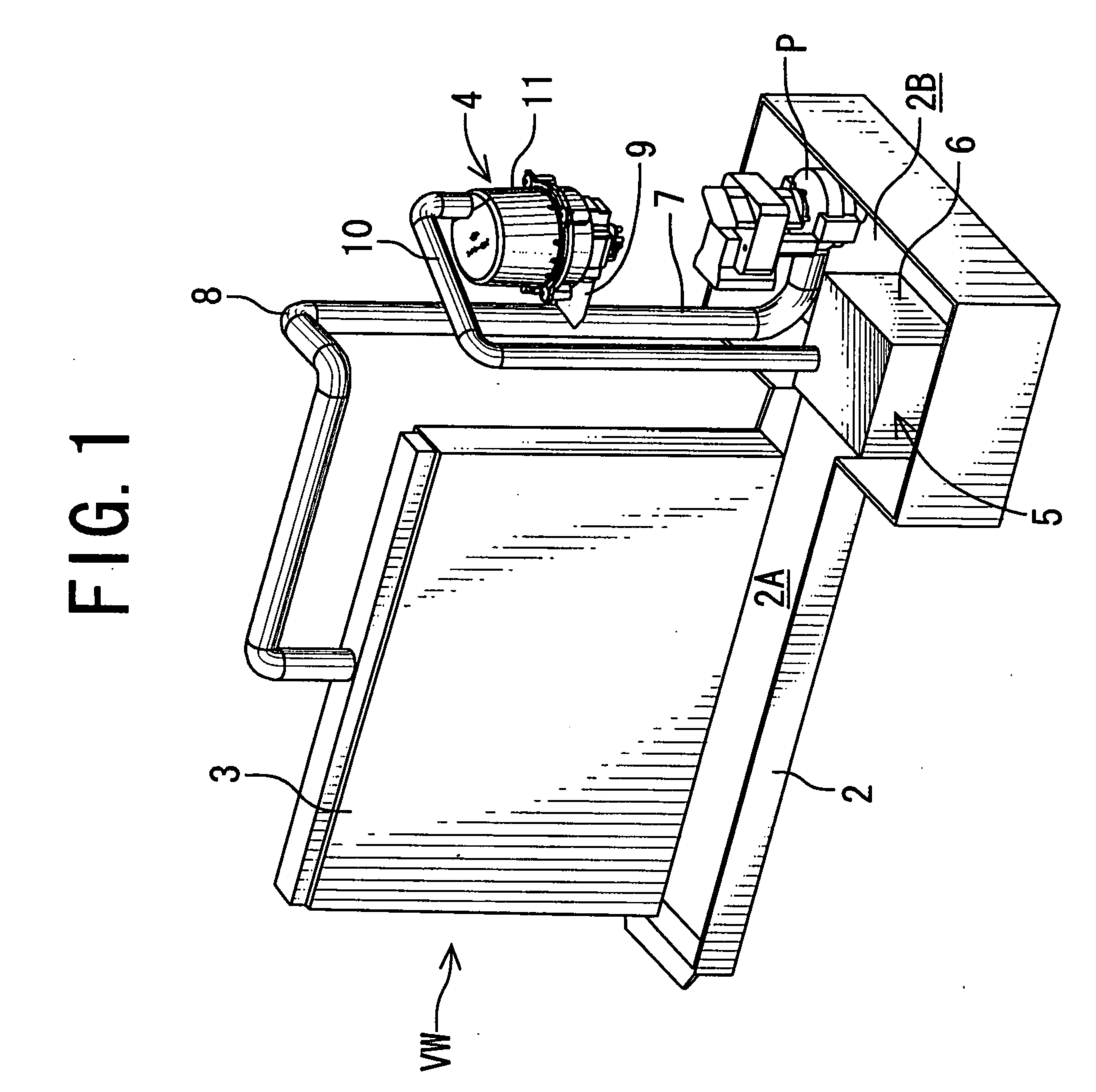

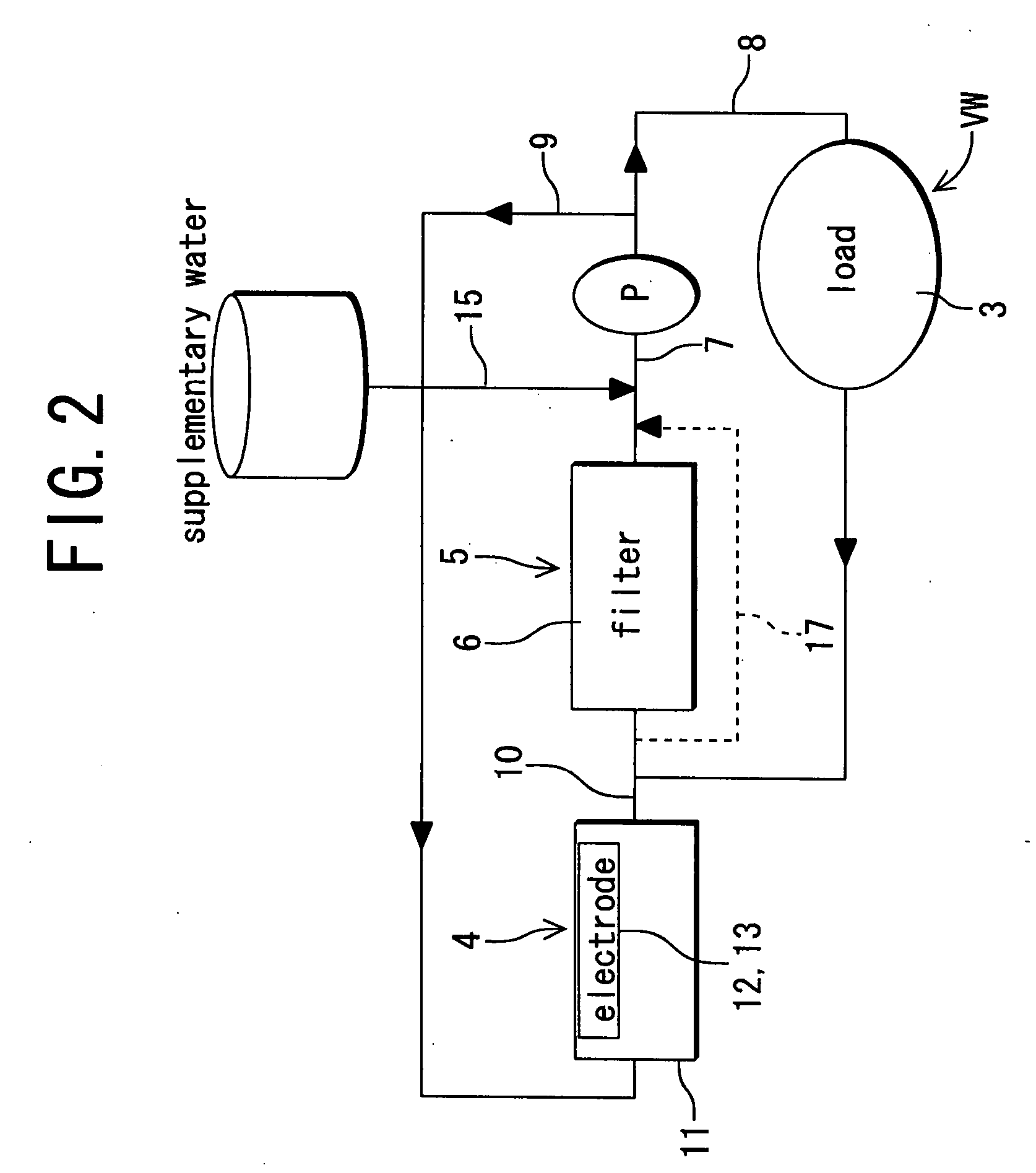

[0027]FIG. 1 shows a schematic constitution diagram of a scale collection system according to one embodiment of the present invention, and FIG. 2 shows a system diagram of the scale collection system shown in FIG. 1, respectively. In the present embodiment, the scale collection system of the present invention is applied to an air bacteria removal device VW. Therefore, a load of the present invention corresponds to an element of the air bacteria removal device VW.

[0028] The air bacteria removal device VW of the present embodiment includes a water reception tray 2 as a water storage section, an element 3 (corresponding to the load of the present invention) disposed on an upper surface of this water reception tray 2, an electrolytic cell 11, electrolytic treatment means 4 including a pair of electrodes 12, 13 (the electrodes are not shown in FIG. 1) and the like, scale collection means 5 disposed on a downstream side (an outlet side) of the electrolytic treatment means 4, and a pump P...

embodiment 2

[0050] Next, a scale collection system of another embodiment (a second embodiment) will be described with reference to FIG. 3. In the embodiment, the scale collection system is applied to an air bacteria removal device VW in the same manner as in Embodiment 1. FIG. 3 is a system diagram of the scale collection system of the present embodiment. It is to be noted that in FIG. 3, components denoted with the same reference numerals as those of FIGS. 1 and 2 produce similar effects and perform functions, and hence description thereof is omitted here.

[0051] In FIG. 3, reference numeral 20 denotes a resolving catalyst as hypochlorous acid resolving means. The resolving catalyst 20 of the present embodiment includes a catalyst which resolves hypochlorous acid in the for-treatment water, and is disposed along a pipe 22. The pipe 22 is one of pipes branched from a pipe 9A, one end of the pipe branched from the pipe 9A extends via the pipe 22, and the other end of the pipe is connected to a m...

embodiment 3

[0069] It is to be noted that in a case where a thermal catalyst such as nickel oxide is used as a resolving catalyst 20, that is, a catalyst is used which does not resolve hypochlorous acid in for-treatment water at ordinary temperature and which is heated to a predetermined temperature to perform a catalyst function and resolve hypochlorous acid in the for-treatment water, unlike Embodiment 2, the pipe 22 and the three-way valve 25 are not disposed. As shown in FIG. 6, the resolving catalyst 20 can be interposed along a pipe 9. In this case, heating means (e.g., a heater 27) capable of heating the resolving catalyst 20 to the predetermined temperature is attached to the resolving catalyst 20. It is to be noted that in a case where nickel oxide is used as the resolving catalyst 20, since the catalyst is heated at 40° C. to 70° C. to perform a resolving function, energization of the heater 27 needs to be controlled so that nickel oxide is heated at a temperature of 40° C. to 70° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wettability | aaaaa | aaaaa |

| polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com