Exhaust heat recovering device

a heat recovery device and exhaust gas technology, applied in the direction of indirect heat exchangers, machines/engines, light and heating apparatus, etc., can solve the problems of no consideration particularly seen regarding the heat of the insulating part formed, waste heat of the exhaust gas will no longer be able to be transported to the condenser, etc., to achieve reliable heat transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

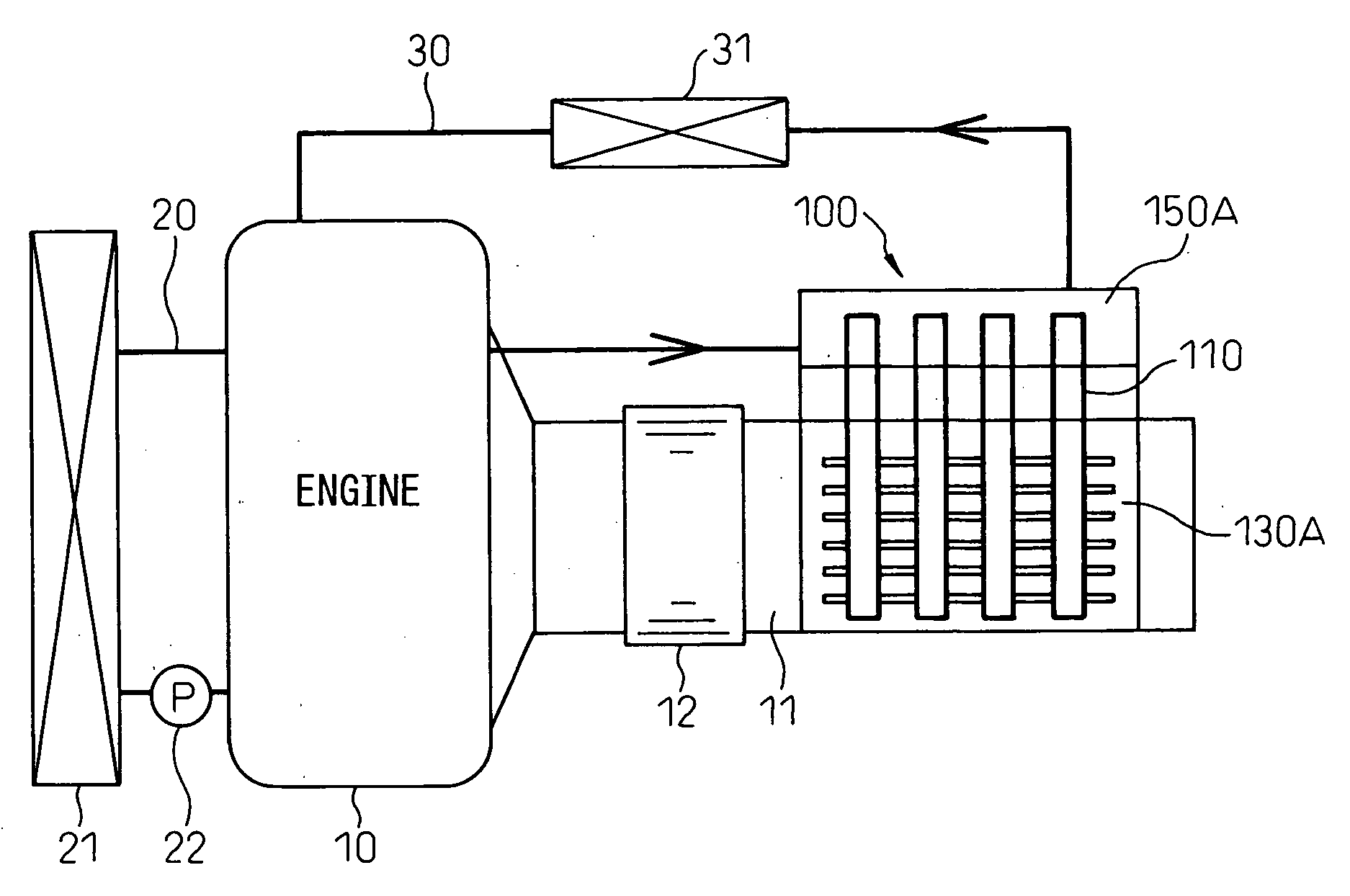

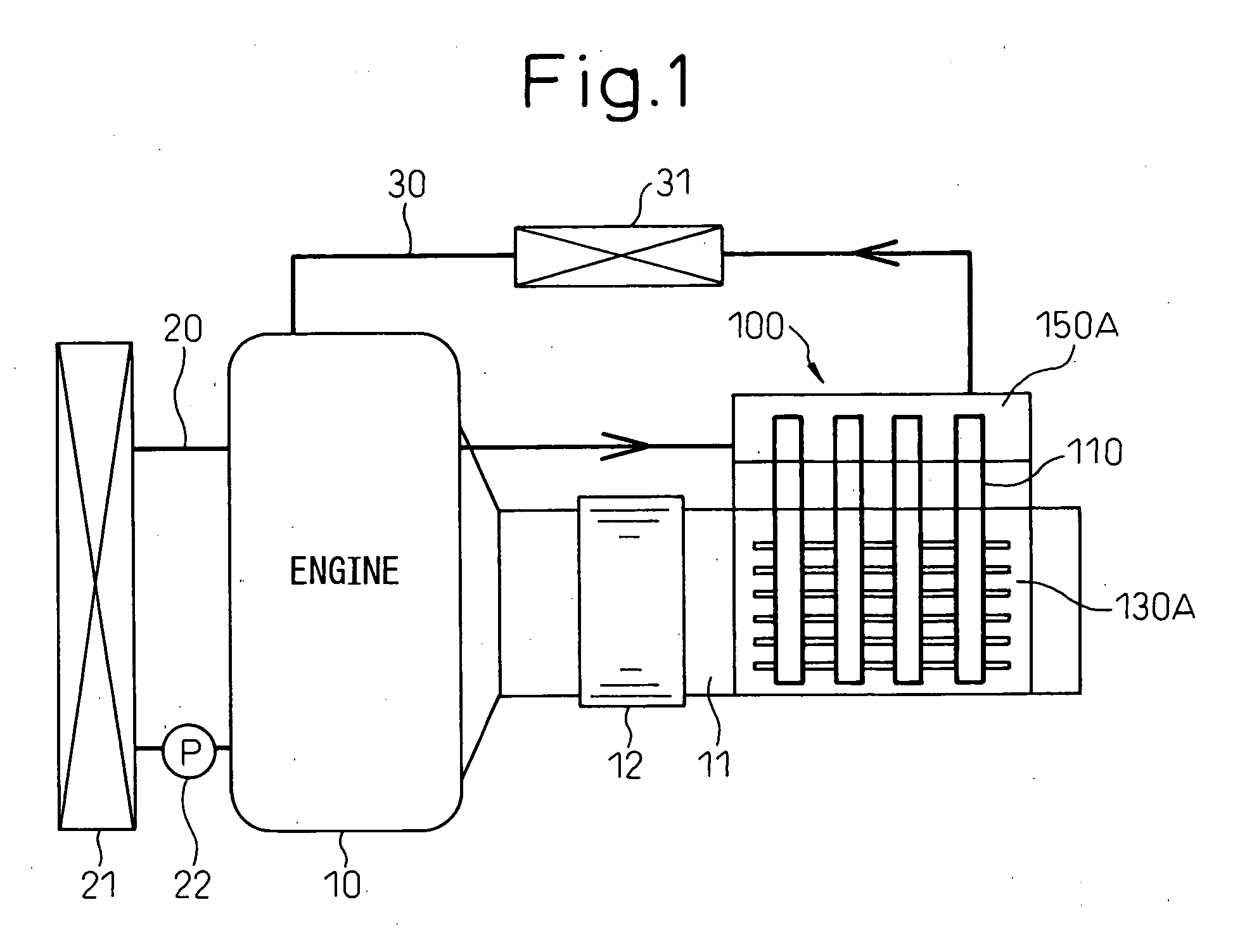

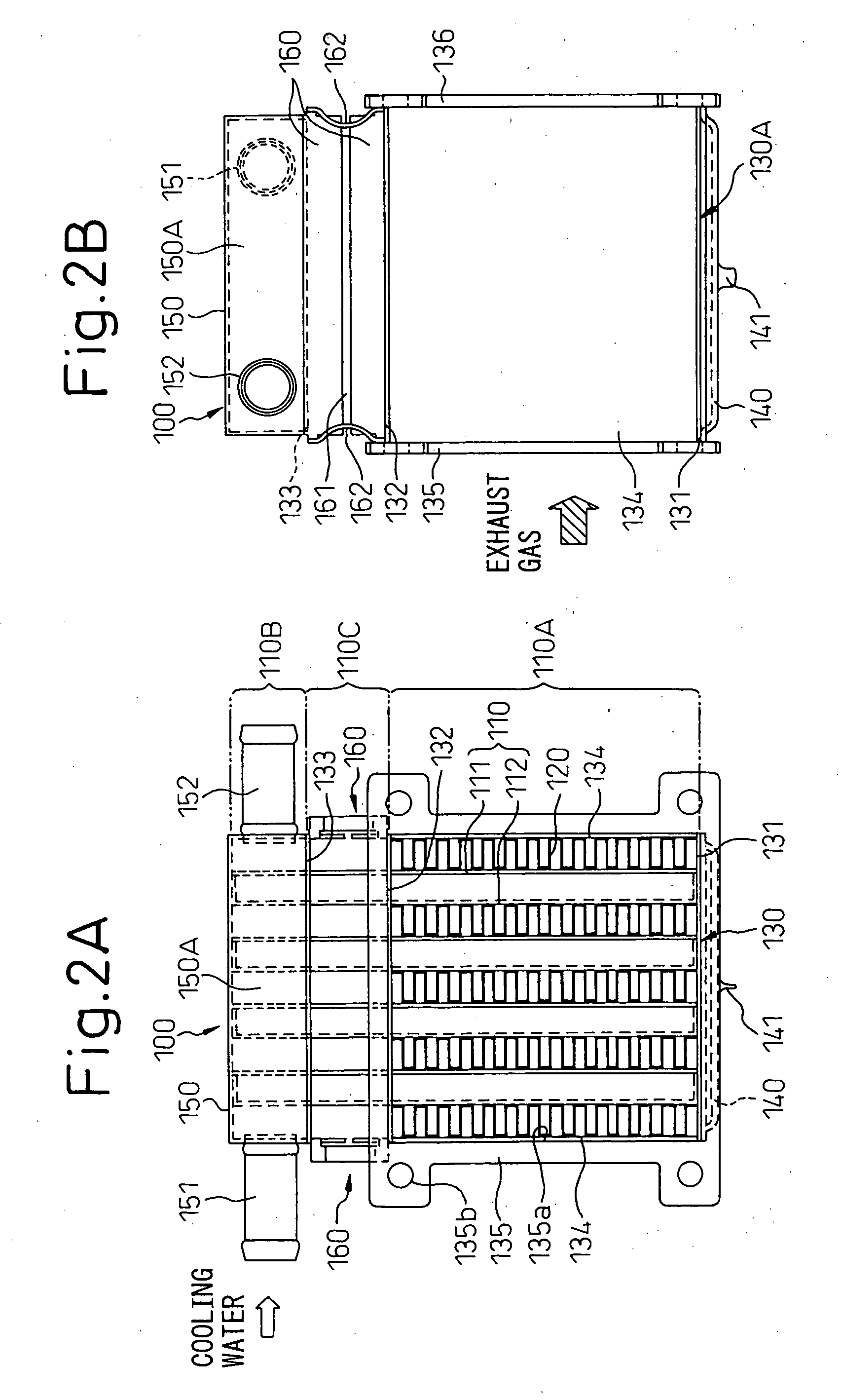

[0032]A first embodiment of the present invention is shown in FIG. 1 to FIG. 3. First, the specific configuration will be explained. A waste heat recovery system 100 of the present embodiment is applied to a vehicle (automobile) having an engine 10 as a drive source for running. In this connection, FIG. 1 is a schematic view showing the state of the waste heat recovery system 100 mounted in a vehicle, FIG. 2A is a front view showing the waste heat recovery system 100, FIG. 2B is a right side view of FIG. 2A, and FIG. 3 is a graph showing the amount of heat transferred to the engine cooling water by the waste heat recovery system 100.

[0033]As shown in FIG. 1, a vehicle engine 10 is a water-cooled internal combustion engine which has an exhaust pipe 11 from which exhaust gas is exhausted after fuel is burned. The exhaust pipe 11 is provided with a catalytic converter 12 for purifying the exhaust gas.

[0034]Further, the engine 10 has a radiator circuit 20 by which the engine 10 is coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com