[0002]In general, prior tonneau covers have been of two types: hard and soft. Soft covers have been essentially formed from a fabric cover mounted over a

metal frame. The frame typically extends about the periphery of the pick-up

truck bed. The fabric can be vinyl or cloth or other flexible material, usually one that is waterproof or

water resistant. The fabric can be a single

cut piece or multiple pieces sewn together. Multiple pieces can be less costly to produce that a single cut piece, but have occasionally had the

disadvantage of seam leakage. Coatings or special assembly can be used to reduce seam leakage, but that can add to production costs and may wear off in time.

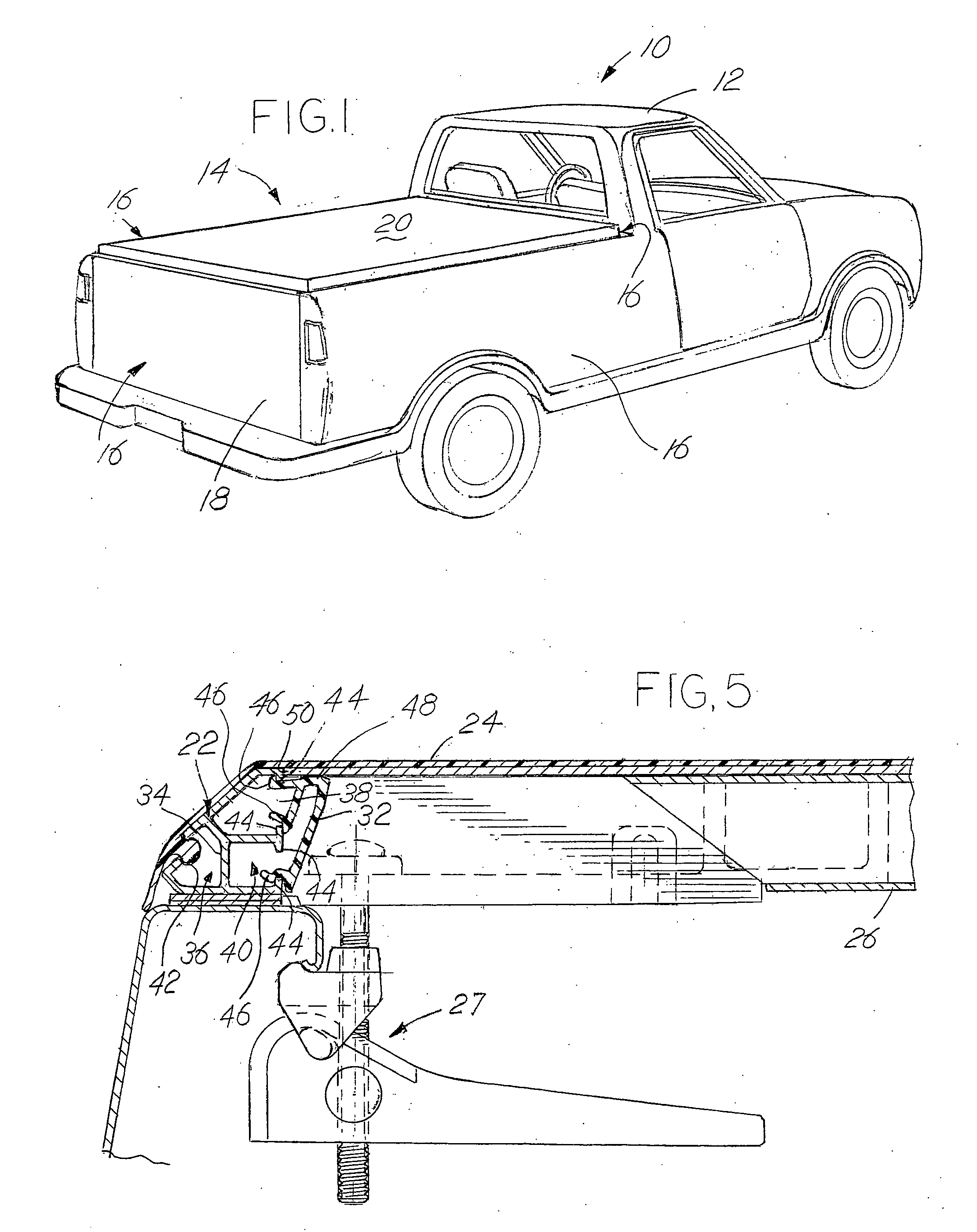

[0004]In contrast, hard covers are typically formed with a

metal, fiberglass or other rigid panel member or series of members that are often permanently connected to a

peripheral frame. The frame and cover are them removably mounted to the side walls of the pick-up truck

bed, frequently as a completed unit after initial assembly. In many cases, hard covers tend to be generally flat or slightly bowed across the opening of the pick-up truck bed, as compared with the somewhat more bowed appearance of soft covers. By comparison to soft covers, hard covers tend to be heavier in weight and take up more storage space when removed from the pick-up truck. This extra weight and / or the bulkier size of hard covers frequently requires at least two persons to remove and / or install the cover. By comparison, some soft covers can be removed or installed by a single person.

[0005]Hard cover and soft cover tonneau covers also differ in other features. Hard covers tend to be more waterproof and resistant of theft of pick-up truck bed contents. Hard covers tend to withstand greater loads from

snow or items / persons placed on top of the tonneau cover. Hard covers are less prone to tearing and puncture damage in general than many soft covers. Hard covers are less prone to deformation at higher speeds of travel and, thus may provide some benefits to vehicle

fuel efficiency in that regard as well as to overall product durability and

longevity. On the other hand, hard covers do not typically have a “soft”

look and feel, such as that resembling a

convertible top automobile. Moreover, the lighter weight of soft covers can benefit overall vehicle fuel economy more in that way. Given the tremendous variety in hard and soft covers, it is hard to say that one or the other will normally be less expensive, but in general the price range of soft covers goes lower than hard covers. Accordingly, tonneau cover users may start out with a soft cover, but over time may desire to

upgrade to a hard cover.

[0006]Accordingly, it is an object of the present invention to provide improved tonneau cover assemblies. More particularly, objectives of the present invention include providing soft cover tonneaus with many of the advantages of hard covers, but without some of the drawbacks of hard covers. For example, those objectives would include greater durability and theft protection, greater

water resistance, better fuel economy from shape maintenance, and larger load endurance while keeping costs and overall weight low and maintaining a soft

look and feel and ease of installation and removal. At the same time, it is an objective of the present invention to be able to provide these advantages both prospectively to new tonneau covers and ones already in use. Further, it is an objective of the present application to enable application of these advantages to other fabric and frame enclosures, just as tents, caravans, awnings,

patio covers and the like.

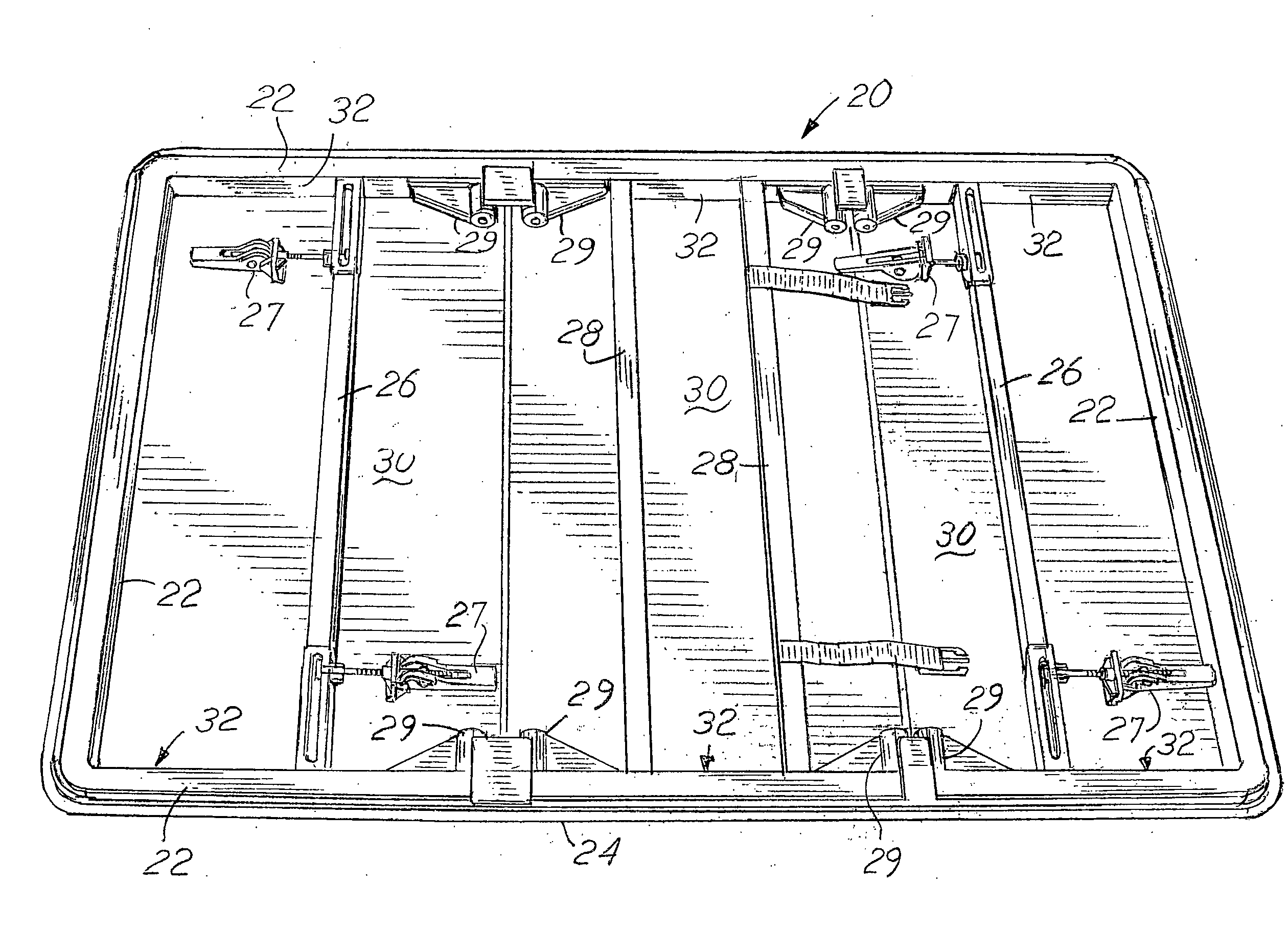

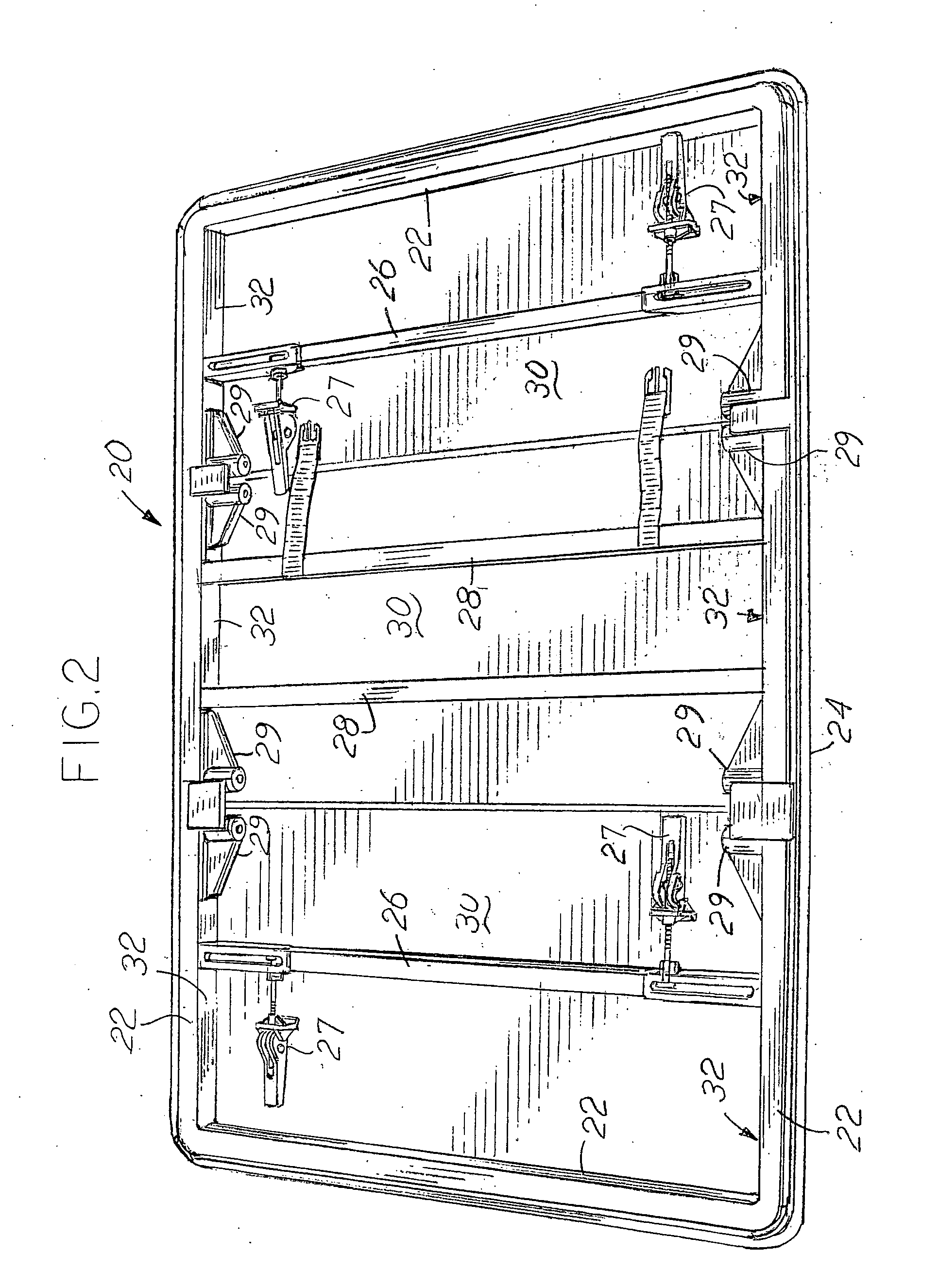

[0007]These and other objects of the present invention are obtained by the provision of a tonneau cover assembly having a plurality of substantially rigid panels inserted between the fabric and the bows and then locked into place and / or supported by snap-fit elements connecting to the

peripheral frame of the tonneau cover. The snap-fit elements can also serve to positively locate the bows with respect to the frame. The panels can be closely dimensioned with respect to the distance across the frame or spaced somewhat to accommodate

insertion about frame hinges and / or close fitting fabric, bows and frames. Two sided

adhesive tape can be used between the panels and the snap-fit elements and the bows to maintain panel placement in the event that the assembly is to be a permanent aspect of the tonneau cover. Panels can also be perforated for weight reduction and / or

cost savings without significant loss of theft security. Panels can be padded for

impact absorption without permanent deformation so as to maintain tonneau cover attractiveness despite significant

wear and tear during use. Other objects, advantages and novel features of the present invention will become readily apparent to those skilled in the art from the following detailed description of preferred embodiments.

Login to View More

Login to View More  Login to View More

Login to View More